Supply chain risk management demands more than reactive firefighting. You need structured identification of vulnerabilities, deliberate assessment of exposure levels, and targeted mitigation strategies that protect operations before disruptions occur.

This systematic approach begins with mapping your entire supply network. Include primary suppliers, but extend visibility deeper. Tier 2 suppliers face a 21% higher disruption risk, and Tier 3 suppliers up to 38%. Understanding these dependencies reveals where your operations are most vulnerable.

The framework involves four interconnected phases. First, identify potential threats across all tiers of your supply chain. Second, assess the likelihood and potential impact of each risk. Third, implement specific mitigation strategies tailored to your highest-priority vulnerabilities. Fourth, establish continuous monitoring systems that detect early warning signals.

Technology amplifies your capabilities across all four phases. Real-time tracking systems provide visibility into supplier performance. Predictive analytics identify patterns that signal emerging risks. Invest in platforms that provide real-time monitoring across all supplier tiers to maintain current intelligence on your supply network health.

The business case for systematic risk management has strengthened considerably. Over 70% of companies now prioritize risk resilience as a top investment, recognizing that disruption costs far exceed prevention investments.

This article examines practical approaches developed through real-world application. You’ll learn specific tactics for identifying vulnerabilities, assessing exposure, implementing protective measures, and maintaining vigilance. The strategies presented work across industries and scale to operations of varying complexity.

Understanding Supply Chain Risk Management Fundamentals

Supply chain risk management is the structured process of identifying, evaluating, and controlling threats that could disrupt the flow of materials, information, or finished products through your network.

The scope extends beyond your direct suppliers. Your supply chain includes transportation providers, warehousing operations, information systems, financial arrangements, and regulatory compliance across multiple jurisdictions. Each connection point represents a potential vulnerability.

Core Risk Categories

Operational risks stem from internal processes and capabilities. Equipment failures, quality issues, capacity constraints, and workforce disruptions fall into this category. These risks often have immediate impact but remain within your sphere of influence.

Financial risks include supplier insolvency, currency fluctuations, payment delays, and credit availability. A supplier’s financial instability can cascade through your operations, creating shortages even when demand remains steady.

External risks originate outside your direct control. Geopolitical tensions, natural disasters, regulatory changes, and cybersecurity threats require different mitigation approaches than operational challenges.

Why Traditional Approaches Fall Short

Many organizations treat supply chain risk management as an administrative task. They maintain supplier lists, conduct periodic audits, and document contingency plans. This compliance-focused approach misses the dynamic nature of modern supply networks.

Supply chains constantly evolve. Suppliers change their sourcing strategies. Transportation routes shift due to economic factors. New regulations alter compliance requirements. Yesterday’s risk assessment quickly becomes outdated.

Effective risk management requires ongoing attention, not annual reviews. The most resilient organizations embed risk awareness into daily operations, empowering teams to identify and escalate emerging threats before they materialize into disruptions.

The Four-Stage Risk Management Process

Building from these fundamentals, implementing structured processes transforms risk management from reactive to proactive. The four-stage framework provides the organizational approach needed for sustained resilience.

Stage One: Risk Identification

Start by mapping your complete supply network. Document every supplier, their geographic locations, and their dependencies on sub-tier suppliers. Include logistics providers, technology systems, and regulatory requirements.

Conduct structured interviews with operational teams. Warehouse managers, procurement specialists, and logistics coordinators possess ground-level insights into potential vulnerabilities. Their daily experiences reveal risks that executive-level reviews might miss.

Examine historical disruptions within your industry. Analyze which events caused the most significant impacts and how similar risks might affect your current operations. Industry reports and trade associations provide valuable data on emerging threat patterns.

Create a risk register that catalogs identified threats. Include the risk category, potential trigger events, affected operations, and preliminary severity estimates. This living document becomes the foundation for subsequent assessment and mitigation work.

Stage Two: Risk Assessment

Evaluate each identified risk along two dimensions: likelihood of occurrence and potential business impact. This assessment determines where to focus mitigation resources.

Likelihood assessment requires honest evaluation. Consider historical frequency, current conditions, and trend trajectories. A supplier located in a region with increasing geopolitical tensions faces higher disruption likelihood than one in a stable area.

Impact assessment examines consequences across multiple dimensions. Financial costs matter, but also consider operational downtime, customer relationship damage, regulatory penalties, and reputational harm. Some disruptions create effects that persist long after immediate operations resume.

| Risk Factor | Assessment Approach | Key Considerations |

|---|---|---|

| Supplier Financial Health | Credit reports, payment patterns, financial statements | Debt levels, cash flow stability, ownership structure |

| Geographic Exposure | Regional analysis, climate data, political stability indices | Natural disaster frequency, infrastructure quality, regulatory environment |

| Operational Capacity | Facility audits, production data, quality metrics | Equipment age, workforce skills, quality control systems |

| Cybersecurity Posture | Security assessments, incident history, system architecture | Data protection measures, access controls, backup systems |

Plot risks on a matrix with likelihood on one axis and impact on the other. High-likelihood, high-impact risks demand immediate attention. Low-likelihood, low-impact risks might accept monitoring without active mitigation.

Stage Three: Risk Mitigation

Develop specific strategies for your highest-priority risks. Mitigation approaches fall into four categories: avoidance, reduction, transfer, and acceptance.

Risk avoidance eliminates exposure entirely. If a supplier’s risk profile proves unacceptable, sourcing from alternative providers removes the threat. This approach works when viable alternatives exist without creating new vulnerabilities.

Risk reduction implements controls that decrease likelihood or impact. Diversifying your supplier base reduces dependence on single sources. Building inventory buffers minimizes disruption from short-term supply interruptions. Strengthening supplier relationships improves communication and collaborative problem-solving.

Risk transfer shifts potential losses to other parties. Insurance coverage, contractual liability clauses, and financial hedging instruments move financial exposure. Note that transfer addresses financial consequences but doesn’t eliminate operational disruption.

Risk acceptance acknowledges some threats as unavoidable or too costly to mitigate. Document these decisions explicitly, including the rationale and circumstances that might trigger reconsideration.

Stage Four: Continuous Monitoring

Establish systems that track risk indicators and supplier performance in real time. Technology platforms integrate data from multiple sources, providing early warning of emerging issues.

Define key risk indicators for each major threat. Supplier financial metrics, quality performance trends, delivery reliability, and external factors like weather patterns or regulatory announcements all provide signals.

Schedule regular risk reviews with cross-functional teams. Quarterly assessments work for most organizations, with more frequent reviews for high-exposure areas. These sessions evaluate whether risk profiles have changed and mitigation strategies remain effective.

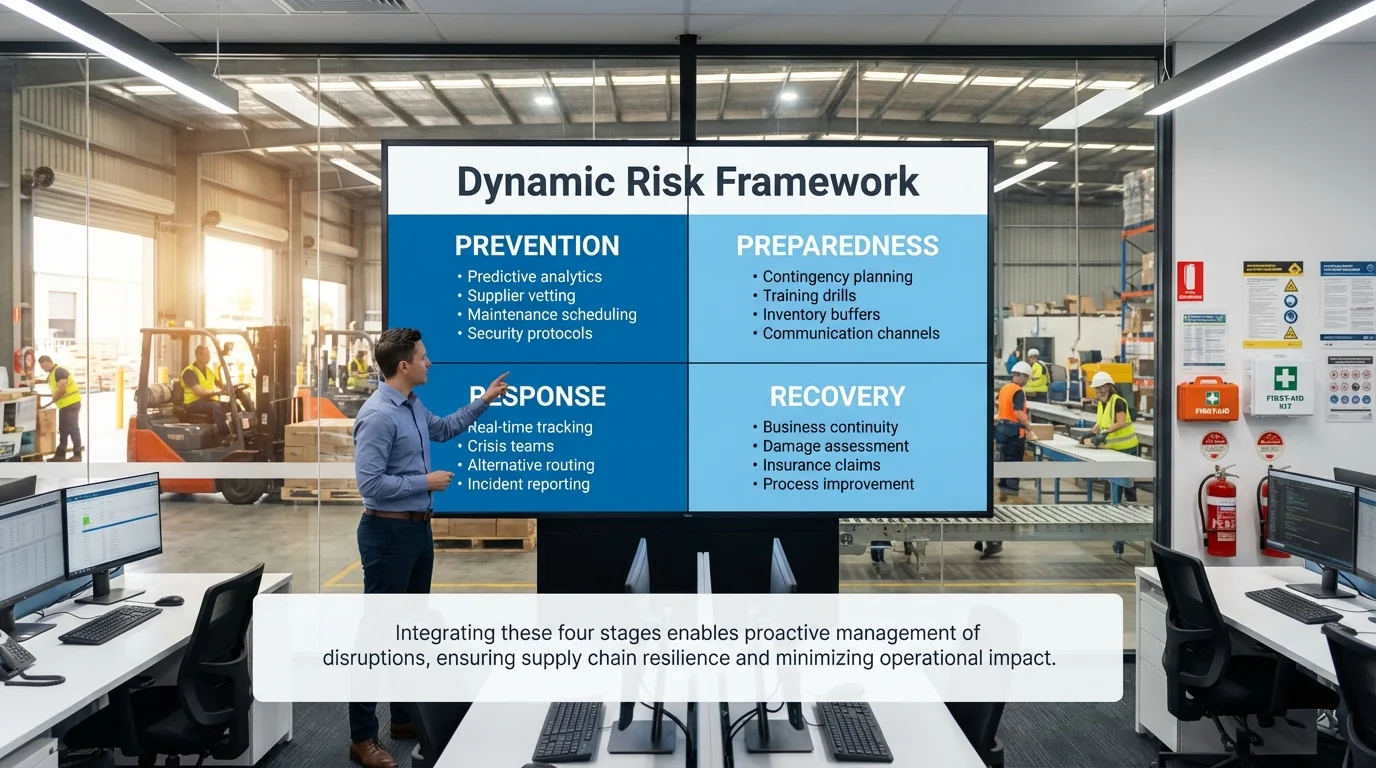

Apply the prevention, preparedness, response, and recovery model to ensure ongoing resilience. This framework keeps risk management dynamic, adapting to changing conditions rather than following static protocols.

Essential Supply Chain Risk Mitigation Strategies

With processes established, specific tactical approaches address the most common supply chain vulnerabilities. These strategies build resilience across different risk categories.

Supplier Diversification

Avoid concentration risk by qualifying multiple suppliers for critical materials and components. Single-source dependencies create fragility, leaving you vulnerable when that supplier experiences problems.

Develop at least two qualified suppliers for components representing significant revenue exposure or long lead times. Three or more suppliers provide even stronger protection for your most critical inputs.

Balance diversification against efficiency considerations. Splitting orders among multiple suppliers increases coordination complexity and may reduce economies of scale. Target diversification where disruption risk justifies these trade-offs.

Geographic diversification protects against regional disruptions. Source from suppliers in different countries or regions to minimize exposure to localized events like natural disasters, political instability, or regional infrastructure failures.

Strategic Inventory Management

Inventory buffers provide time to respond when supply disruptions occur. Strategic stockpiles of critical materials prevent production stoppages during short to medium-term supplier outages.

Calculate optimal safety stock levels based on supply variability, lead times, and criticality to operations. Higher variability and longer lead times require larger buffers. Items with readily available alternatives need less protective inventory.

Consider consignment inventory arrangements where suppliers maintain stock at your facilities. This approach provides buffer protection without tying up your working capital, though it requires suppliers with sufficient financial strength.

Balance inventory costs against disruption costs. Carrying excess inventory ties up capital and risks obsolescence. Calculate the break-even point where buffer inventory costs equal expected disruption losses.

Supplier Relationship Strengthening

Collaborative relationships with key suppliers improve communication, facilitate joint problem-solving, and increase your priority during allocation decisions.

Share forecasts and planning information with strategic suppliers. Better visibility into your requirements helps them plan capacity and manage their own supply chains more effectively. This transparency reduces surprises that could trigger allocation or quality issues.

Conduct regular business reviews with important suppliers. Discuss performance trends, upcoming changes, and improvement opportunities. These structured conversations build relationship depth beyond transactional interactions.

Develop joint contingency plans for potential disruptions. Work with suppliers to identify alternative production sites, backup transportation routes, and communication protocols during emergencies. Planning together before crises occur enables faster, more coordinated responses.

Consider supplier development programs that help build capabilities. Technical assistance, quality improvement support, or financial stability programs strengthen your supply base while deepening relationships.

Enhanced Supply Chain Visibility

Visibility into supplier operations, transportation status, and inventory positions enables proactive risk response. Technology platforms aggregate data from across your supply network into unified dashboards.

Implement supplier portals that capture performance data, certification status, and quality metrics. Automated data collection reduces manual reporting burden while providing current intelligence.

Deploy transportation tracking systems that provide real-time location data for shipments. GPS tracking, electronic logging, and carrier integration platforms show exactly where materials are in the logistics network.

Extend visibility beyond first-tier suppliers into sub-tier relationships. Understanding who supplies your suppliers reveals hidden dependencies and concentration risks.

Cybersecurity Risk Management

Digital integration creates cyber vulnerabilities across supply chains. A breach at a supplier can compromise your data, disrupt operations, or create compliance violations.

Require cybersecurity assessments as part of supplier qualification. Evaluate their data protection practices, access controls, incident response capabilities, and business continuity plans.

Limit supplier access to only the systems and data they require. Implement strong authentication, encrypt sensitive data, and monitor access patterns for anomalies.

Include cybersecurity requirements in supplier contracts. Specify security standards, breach notification obligations, and liability provisions. Regular audits verify ongoing compliance.

Develop incident response plans that address supplier-related cyber events. Define communication protocols, containment procedures, and recovery steps for scenarios where supplier breaches affect your operations.

Leveraging Technology for Risk Management

Technology amplifies human judgment in risk management. The right tools provide capabilities impossible through manual processes alone.

Artificial Intelligence and Machine Learning

AI systems analyze vast datasets to identify risk patterns and predict potential disruptions. Machine learning algorithms detect subtle correlations that human analysts might miss.

Predictive models process supplier performance data, external risk indicators, and historical patterns to forecast disruption probability. These insights enable preventive action before issues escalate.

Natural language processing monitors news feeds, social media, and regulatory announcements for events affecting your supply chain. Automated alerts notify teams of potential risks as information emerges.

Start with focused applications rather than enterprise-wide deployments. Target AI tools at your highest-priority risks or most data-rich processes. Early successes build organizational confidence and funding for broader adoption.

Internet of Things Sensors

IoT devices provide real-time data on product location, environmental conditions, and asset status throughout the supply chain.

Temperature sensors on shipments ensure cold-chain integrity for sensitive products. Location trackers provide current position data. Vibration monitors detect handling issues that might cause damage.

This sensor data feeds into analytics platforms that identify deviations from normal patterns. Automated alerts enable rapid response when conditions fall outside acceptable ranges.

Blockchain for Supply Chain Transparency

Blockchain technology creates immutable records of transactions and product movements. This transparency builds trust and facilitates tracing when issues arise.

Smart contracts automate compliance verification and payment processing based on predefined conditions. Goods meeting specified quality standards trigger automatic payment, reducing transaction friction.

Product provenance tracking through blockchain verifies authenticity and ethical sourcing. Each participant records their handling, creating an auditable chain from origin to final customer.

Cloud-Based Risk Management Platforms

Integrated platforms consolidate risk data, assessment workflows, and monitoring dashboards into unified systems. Cloud deployment provides accessibility, scalability, and automatic updates.

Look for platforms offering supplier management, risk assessment tools, compliance tracking, and reporting capabilities. Integration with ERP, procurement, and logistics systems eliminates manual data transfer.

Vendor selection should consider your organization’s size, complexity, and specific risk profile. Larger enterprises need extensive customization and integration capabilities. Smaller organizations benefit from pre-configured solutions with faster implementation.

Building Organizational Risk Awareness

Technology and processes provide the framework, but organizational culture determines whether risk management succeeds. Building risk awareness across all levels creates sustainable resilience.

Cross-Functional Risk Committees

Establish teams representing procurement, operations, logistics, quality, finance, and legal functions. This diverse perspective ensures comprehensive risk evaluation.

Meet regularly to review risk assessments, discuss emerging threats, and coordinate mitigation activities. Quarterly meetings work for most organizations, with additional sessions during significant changes or events.

Define clear escalation paths for urgent risks. Team members need authority to raise immediate concerns and trigger emergency protocols when situations demand rapid response.

Training and Education Programs

Educate employees about supply chain risks, their role in prevention, and procedures for reporting concerns. Training creates shared understanding and empowers proactive risk identification.

Tailor content to different organizational levels. Executives need strategic context and business impact understanding. Operational teams need practical skills for recognizing and responding to specific risk indicators.

Include scenario-based exercises that simulate disruption events. Working through realistic situations builds muscle memory and reveals process gaps before real emergencies occur.

Performance Metrics and Accountability

Measure risk management effectiveness through specific indicators. Track metrics like supplier disruption frequency, risk assessment currency, mitigation plan completion rates, and incident response times.

Include risk management performance in employee evaluations and incentive structures. Accountability mechanisms ensure risk awareness translates into action.

Share performance data transparently across the organization. Visibility into progress and gaps maintains focus and demonstrates leadership commitment.

Responding to Geopolitical and Natural Disaster Risks

External disruptions beyond organizational control require specialized approaches. Geopolitical tensions and natural disasters represent two critical categories demanding attention.

Geopolitical Risk Management

Political instability, trade disputes, sanctions, and regional conflicts can disrupt supply chains rapidly. These events often emerge with limited warning, requiring advance preparation.

Monitor geopolitical developments in regions where you source materials or manufacture products. Subscribe to risk intelligence services that analyze political stability, trade policy changes, and conflict potential.

Develop contingency plans for high-risk regions. Identify alternative suppliers in different geographies. Maintain modest inventory buffers for materials sourced from politically unstable areas. Document procedures for rapid supplier switching if situations deteriorate.

Consider the political risk profile when making long-term sourcing decisions. Lower-cost regions might carry higher disruption probability. Evaluate whether cost savings justify the additional risk exposure.

Natural Disaster Preparedness

Earthquakes, hurricanes, floods, and other natural disasters can devastate supply chains. While unpredictable in timing, these events follow geographic patterns enabling preparation.

Map supplier locations against natural disaster risk zones. Identify concentrations in earthquake-prone areas, flood plains, or hurricane corridors. Geographic diversification reduces exposure to regional weather events.

Require business continuity plans from suppliers in high-risk zones. Plans should document backup facilities, data recovery capabilities, and communication protocols during emergencies.

Establish communication procedures for natural disaster scenarios. Define check-in requirements, contact escalation paths, and information-sharing protocols. Test these procedures regularly through tabletop exercises.

Managing Compliance and Regulatory Risks

Regulatory environments grow increasingly complex. Compliance failures create legal exposure, financial penalties, and reputational damage.

Regulatory Monitoring Systems

Track regulatory changes affecting your supply chain across all jurisdictions where you operate. Environmental regulations, labor standards, product safety requirements, and trade compliance rules all evolve continuously.

Subscribe to regulatory update services specific to your industry. Professional associations, legal firms, and specialized consultancies provide monitoring and analysis of regulatory developments.

Designate compliance owners for each regulatory domain. These individuals track changes, assess impacts, and coordinate necessary adjustments to processes or supplier requirements.

Supplier Compliance Management

Extend compliance oversight to suppliers whose actions create liability for your organization. Environmental violations, labor abuses, or quality failures at supplier facilities can trigger legal and reputational consequences.

Incorporate compliance requirements into supplier contracts. Specify standards, audit rights, certification requirements, and consequences for non-compliance.

Conduct regular compliance audits using qualified third parties. Independent verification provides assurance and demonstrates due diligence to regulators and stakeholders.

Develop corrective action processes for identified compliance gaps. Work with suppliers on improvement plans, but maintain willingness to exit relationships where compliance commitment proves inadequate.

Creating Effective Business Continuity Plans

Business continuity planning prepares organizations to maintain operations during disruptions. These plans translate risk management into operational procedures.

Scenario Planning

Develop response plans for your most significant risk scenarios. A major supplier bankruptcy requires different actions than a natural disaster or cyberattack. Scenario-specific plans enable faster, more effective responses.

For each scenario, document trigger events, immediate actions, communication procedures, alternative supply arrangements, and recovery steps. Assign clear responsibilities for each action item.

Validate plans through realistic exercises. Simulations reveal gaps, test decision-making processes, and build team familiarity with emergency procedures.

Communication Protocols

Effective crisis communication keeps stakeholders informed and coordinates response activities. Establish protocols before emergencies occur.

Create contact lists for key stakeholders including suppliers, logistics providers, customers, internal teams, and external advisors. Verify contact information quarterly.

Define communication cadences for different disruption severities. Minor issues might warrant weekly updates. Major disruptions require daily or more frequent communication.

Designate official spokespersons authorized to communicate externally during crises. Consistent messaging prevents confusion and maintains stakeholder confidence.

Recovery Prioritization

Not all operations require simultaneous recovery. Prioritize restoration efforts based on business criticality, customer commitments, and resource availability.

Identify your most critical products, customers, and processes. Focus initial recovery efforts on capabilities generating the most significant revenue or serving your most important relationships.

Document recovery time objectives for different operational areas. Some processes must resume within hours. Others can tolerate longer restoration timelines. Clear objectives guide resource allocation during recovery.

Measuring and Improving Risk Management Performance

Continuous improvement requires measuring effectiveness and adapting based on results. The following metrics provide insight into risk management performance.

| Metric Category | Specific Measures | Target Frequency |

|---|---|---|

| Disruption Impact | Number of disruption events, downtime duration, financial impact, customer impact | Monthly tracking, quarterly review |

| Process Effectiveness | Risk assessment currency, mitigation plan completion, audit findings, training completion rates | Monthly tracking, quarterly review |

| Supplier Performance | On-time delivery, quality metrics, compliance status, financial health scores | Real-time monitoring, monthly review |

| Response Capability | Incident response time, recovery time, plan exercise completion, communication effectiveness | Per-incident tracking, quarterly aggregation |

Review metrics regularly with leadership and risk management teams. Identify trends, celebrate improvements, and address persistent issues.

Conduct post-incident reviews after significant disruptions. Analyze what worked well, what failed, and what requires improvement. Document lessons learned and update procedures accordingly.

Benchmark performance against industry standards where available. Trade associations and research firms publish supply chain performance data enabling comparative analysis.

Quick Answers to Common Questions

What are the 5 C’s of supply chain management?

The 5 C’s framework includes Cost, Capacity, Competency, Consistency, and Communication. Organizations use these elements to optimize supply chain performance by focusing on efficiency, supplier capabilities, reliability, and effective information sharing.

What is supply chain risk management?

Supply chain risk management is the process of identifying, assessing, and mitigating risks that could disrupt the flow of goods, services, or information within a supply chain. It aims to ensure continuity, compliance, and resilience against various threats.

What are the 7 C’s of supply chain management?

The 7 C’s expand the foundational framework to include Customer focus, Collaboration, Communication, Coordination, Competency, Cost-effectiveness, and Continuous improvement. This approach enhances supply chain integration, efficiency, and adaptability.

Moving from Planning to Protection

Supply chain risk management requires sustained commitment, not one-time projects. The strategies outlined here provide a foundation for building resilience into your operations.

Start with thorough risk identification across your complete supply network. Honest assessment of vulnerabilities reveals where to focus protective efforts. Prioritization ensures limited resources address your most critical exposures first.

Implement specific mitigation strategies matched to your risk profile. Supplier diversification, strategic inventory, enhanced visibility, and technology deployment all strengthen resilience. Choose approaches aligned with your organization’s capabilities and risk tolerance.

Build risk awareness into your organizational culture. Cross-functional collaboration, training programs, and clear accountability create the human infrastructure supporting technical systems and processes.

Measure performance and adapt continuously. Supply chains evolve. Risk profiles shift. Effective risk management remains dynamic, adjusting strategies as conditions change.

The investment in structured risk management pays returns through avoided disruptions, stronger supplier relationships, and operational confidence. Organizations that embed these practices into daily operations build competitive advantages through reliability and resilience.

For specialized guidance on mitigating risks in global supply chains, explore our detailed examination of international supply network protection. Our analysis of supply chain risk management software provides practical insights into technology selection and implementation.

Additional resources on logistics management and fleet management address operational aspects critical to supply chain resilience.