Chain of Responsibility (CoR) is a legal framework extending safety and compliance obligations beyond drivers to all parties in Australia. This means transport safety isn’t just a driver’s problem anymore.

If you schedule freight, load vehicles, manage transport operations, or employ drivers, you have legal obligations under the Heavy Vehicle National Law (HVNL).

The consequences of getting this wrong are significant. Penalties reach $3 million for corporate breaches. But more importantly, understanding CoR protects your people, your operations, and your business reputation.

This guide covers everything you need to know. You’ll learn who CoR applies to, what your primary duty requires, how reasonably practicable measures work, and how to implement effective compliance systems. We’ll also explain the 2026 amendments that make Safety Management Systems a legal requirement.

With 25+ years of supply chain experience and over 600 clients navigating HVNL compliance, we’ve seen what works. Whether you’re a scheduler, consignor, loader, or executive, this guide gives you the practical knowledge to meet your obligations and protect your business.

Understanding the Heavy Vehicle National Law (HVNL)

The Heavy Vehicle National Law (HVNL) governs heavy vehicle operations across Australia. Passed in 2012 and implemented progressively across states, the HVNL created a single national framework for transport safety.

The law applies to vehicles with a Gross Vehicle Mass (GVM) over 4.5 tonnes. This includes trucks, prime movers, truck and trailer combinations, and buses.

The HVNL introduced Chain of Responsibility as its core safety mechanism. Rather than placing all responsibility on drivers, CoR recognizes that many different parties influence the safety of a heavy vehicle on a road.

The National Heavy Vehicle Regulator (NHVR) administers the HVNL. They provide guidance, develop codes of practice, and enforce compliance across the supply chain.

Key HVNL Compliance Areas

The HVNL establishes strict requirements across multiple domains. Each one carries specific obligations and potential penalties.

Fatigue management rules govern work and rest hours for drivers. The law requires accurate recording of work time through written work diaries or Electronic Work Diaries (EWD).

Mass and dimension requirements set legal limits for vehicle weight and size. Exceeding these limits creates serious safety risks and attracts substantial penalties.

Load restraint standards ensure freight is secured properly. Poorly restrained loads can shift during transport, causing vehicle instability and crashes.

Vehicle standards cover roadworthiness, maintenance schedules, and equipment requirements. Vehicles must meet minimum safety standards before entering service.

Speed compliance obligations extend beyond drivers to parties who influence speed decisions. This includes schedulers who set unrealistic delivery timeframes.

The 2026 HVNL Amendments

These amendments represent the most substantial update to CoR since the HVNL began. The changes strengthen obligations and clarify expectations across the supply chain.

The most significant change involves Safety Management Systems. Previously recommended, Safety Management Systems become enforceable legal requirements under the 2026 amendments.

The amendments also introduce clearer guidance on what constitutes reasonable steps. This gives parties better direction on meeting their primary duty obligations.

New codes of practice will provide practical guidance for specific industry sectors. These codes will help parties understand their obligations in real-world contexts.

Who Is Covered by Chain of Responsibility?

CoR doesn’t apply to just one role. It reaches across the entire transport supply chain to anyone who can influence safety outcomes.

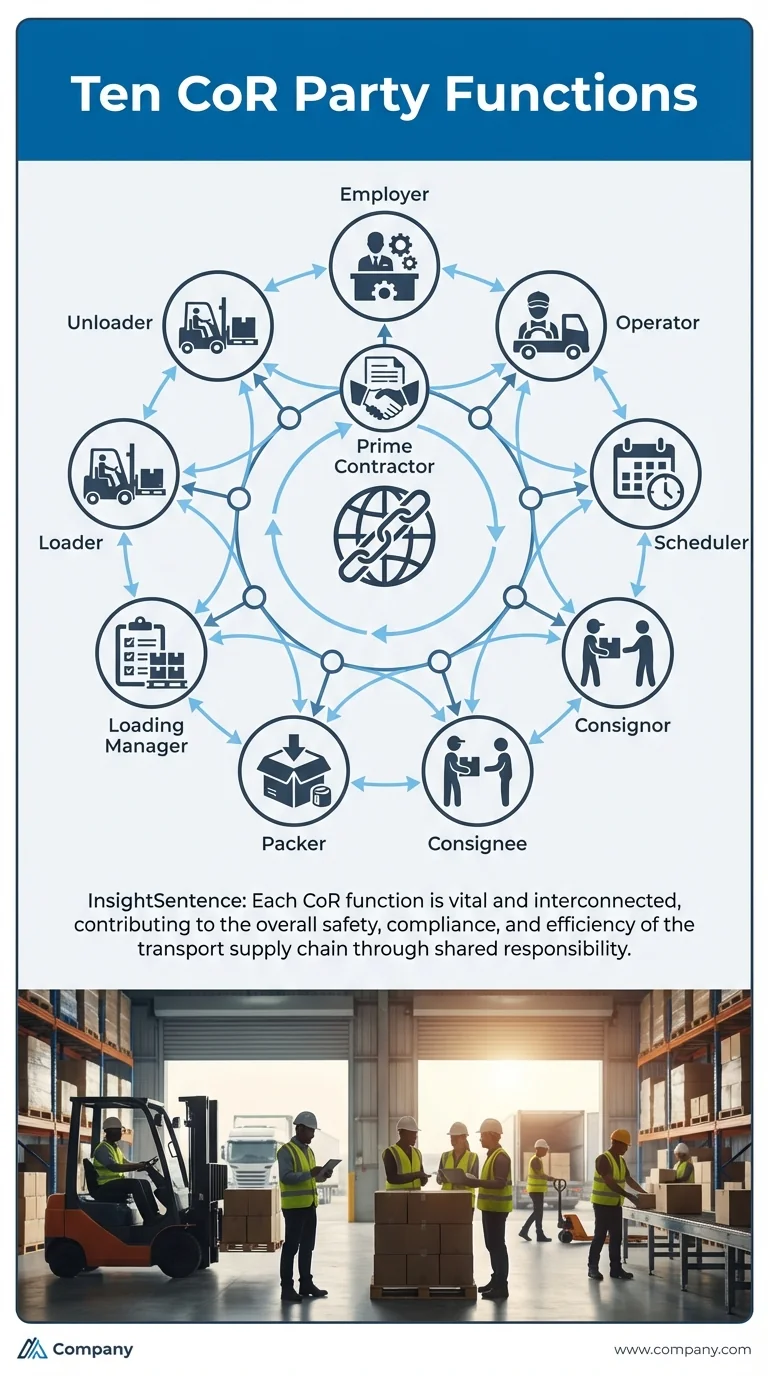

The law identifies ten specific party functions. Each function represents a role that can influence transport safety through decisions or actions.

The Ten CoR Party Functions

Understanding which party functions apply to your business is the first step toward compliance. You might hold multiple functions depending on your operations.

| Party Function | Core Responsibility | Typical Activities |

|---|---|---|

| Employer | Employs or engages drivers | Hiring drivers, setting employment terms, providing training |

| Prime Contractor | Engages another party to transport goods | Contracting transport operators, managing subcontractors |

| Operator | Holds responsibility for vehicle operation | Fleet management, vehicle maintenance, operational decisions |

| Scheduler | Controls or influences driver work and rest times | Setting delivery schedules, allocating jobs, planning routes |

| Consignor | Consigns goods for transport | Preparing freight, arranging transport, packaging goods |

| Consignee | Receives transported goods | Accepting deliveries, unloading requirements, booking appointments |

| Packer | Packs goods into container or onto vehicle | Packing containers, securing cargo inside packages |

| Loading Manager | Supervises or controls loading | Directing loading operations, managing loading areas |

| Loader | Loads goods onto vehicle | Physical loading, weight distribution, securing loads |

| Unloader | Unloads goods from vehicle | Physical unloading, managing unloading procedures |

Most businesses hold multiple party functions simultaneously. A manufacturer might be a consignor, scheduler, and loading manager all at once.

Parties Who Exercise Control or Influence

CoR applies based on control or influence, not job titles. The law looks at what you actually do, not what your business card says.

You’re a CoR party if your decisions or actions affect transport safety outcomes. This includes indirect influence through policies, procedures, or commercial arrangements.

A scheduler who sets tight delivery timeframes exercises control over driver fatigue risks. A consignor who specifies loading methods influences load restraint outcomes.

Even parties without direct operational involvement can be caught by CoR. Finance departments that set payment terms encouraging speeding, or procurement teams that select the cheapest (and potentially non-compliant) carriers.

The test is simple. Can your decisions or actions affect whether a driver complies with the HVNL? If yes, you’re a CoR party.

The Primary Duty Under Chain of Responsibility

Every CoR party must comply with the primary duty. This is the foundation of all HVNL obligations.

The primary duty requires you to ensure the safety of your transport activities, so far as is reasonably practicable. This applies to the scheduling, loading, and operation of a vehicle.

The duty is positive and proactive. You must actively manage risks, not just avoid doing obviously dangerous things.

What the Primary Duty Covers

The primary duty extends across all aspects of heavy vehicle safety under your control or influence.

Fatigue management obligations require you to ensure drivers can comply with work and rest hour requirements. This means realistic scheduling that accounts for traffic, weather, and mandatory rest breaks.

Mass and dimension compliance means ensuring vehicles don’t exceed legal weight limits. You must have systems to verify load weights before vehicles depart.

Load restraint requirements demand properly secured freight. Loads must be restrained to prevent movement during all normal driving conditions.

Vehicle standards obligations ensure vehicles are roadworthy and properly maintained. Maintenance schedules must be followed, and defects addressed before vehicles operate.

Speed compliance extends to anyone who influences speed decisions. Setting delivery schedules that require speeding to achieve violates your primary duty.

Taking Reasonable Steps

Meeting your primary duty means taking reasonable steps to prevent breaches. But what counts as reasonable?

Reasonable steps are practical measures appropriate to your role and circumstances. They’re actions that a reasonable person in your position would take to eliminate or minimize risks.

For schedulers, reasonable steps include building buffer time into delivery schedules. You need to account for potential delays and ensure drivers can rest as required.

For consignors, reasonable steps involve verifying load weights before dispatch. This might mean using weighbridge certificates or on-site weighing systems.

For loading managers, reasonable steps require documented loading procedures and staff training. Workers need clear instructions on weight distribution and restraint methods.

The key is documentation. You must be able to demonstrate what steps you took and why they were appropriate for the risks involved.

What Does ‘Reasonably Practicable’ Mean?

The phrase “reasonably practicable” appears throughout the HVNL. Understanding this concept is critical to compliance.

Reasonably practicable means what’s feasible in your circumstances, considering all relevant matters. It’s not about perfection. It’s about doing what’s reasonable given your situation.

The law requires you to balance several factors when determining what’s reasonably practicable.

Factors in Determining Reasonably Practicable

Five key factors determine what measures are reasonably practicable for your business.

First, consider the likelihood of the risk occurring. Frequent risks demand more robust controls than unlikely scenarios.

Second, assess the degree of harm that might result. Risks that could cause serious injury or death require stronger preventive measures.

Third, evaluate what you know or ought reasonably to know about the risk. Industry knowledge and available information set the baseline for expectations.

Fourth, determine what you know or ought reasonably to know about ways to eliminate or minimize the risk. Available control measures and industry practices matter.

Fifth, weigh the cost of available control measures against the risk. You must consider whether the cost is grossly disproportionate to the risk.

| Factor | What to Consider | Documentation Required |

|---|---|---|

| Likelihood | How often could this risk occur? | Incident records, near-miss reports, industry data |

| Severity | What harm could result? | Risk assessments, safety studies, injury records |

| Knowledge of Risk | What should you know about this hazard? | Industry guidelines, codes of practice, training records |

| Available Controls | What measures could eliminate or reduce risk? | Control options analysis, expert advice, best practice research |

| Cost vs Risk | Is the cost grossly disproportionate? | Cost-benefit analysis, budget records, implementation quotes |

The Hierarchy of Control

When selecting control measures, apply the hierarchy of control. This framework prioritizes more effective solutions over less reliable ones.

Elimination sits at the top. Can you remove the hazard entirely? For example, eliminate fatigue risks by not scheduling loads that require non-compliant driving hours.

Substitution comes next. Can you replace the hazard with something safer? Use lighter packaging materials to reduce vehicle mass.

Engineering controls modify the physical environment. Install weighing systems, use load restraint equipment, or fit telematics to monitor vehicle speed.

Administrative controls change how work is done. Implement procedures, provide training, and establish verification processes.

Personal protective equipment is the last resort. PPE protects the person but doesn’t remove the hazard.

Your reasonable steps should prioritize controls higher in the hierarchy. Relying solely on administrative controls when engineering solutions exist may not be reasonably practicable.

Executive Duty and Due Diligence

Executives hold a separate duty under CoR. This applies to officers of bodies corporate involved in transport.

An executive includes directors, company secretaries, and anyone making decisions affecting substantial parts of the business. The definition is broad and captures senior decision-makers.

The executive duty requires officers to exercise due diligence to ensure their organization complies with the HVNL. You can’t delegate this responsibility away.

What Due Diligence Requires

Due diligence means taking reasonable steps to ensure your organization meets its CoR obligations. The HVNL specifies six elements.

First, acquire and keep up-to-date knowledge of HVNL requirements. Executives must understand the legal framework applying to their operations.

Second, gain an understanding of transport operations and associated hazards. You need to know what your business does and what can go wrong.

Third, ensure appropriate resources and processes exist to eliminate or minimize risks. This means adequate budgets, systems, and personnel.

Fourth, implement processes for receiving and considering information about risks and incidents. You need visibility of transport safety issues.

Fifth, establish processes for timely and appropriate response to incidents and hazards. When problems arise, your organization must act.

Sixth, verify that your organization’s resources and processes are being used. Implementing systems isn’t enough. You must check they’re actually followed.

Demonstrating Due Diligence

Executives demonstrate due diligence through documented actions and evidence of oversight. Saying you care about safety isn’t enough.

Attend transport safety briefings and review CoR performance reports. Document your attendance and the issues discussed.

Ask questions about transport risks in board meetings. Minutes should record your inquiries and management’s responses.

Ensure safety management resources appear in budgets. Adequate funding for training, systems, and equipment demonstrates commitment.

Review incident reports and corrective actions. Your involvement shows you’re monitoring what happens and ensuring appropriate responses.

Commission independent audits of CoR compliance. External verification provides assurance that systems work as intended.

The key is creating a documented trail showing your active involvement in transport safety governance. If prosecution occurs, this evidence may provide a reasonable steps defense.

Key CoR Compliance Areas

CoR obligations span ten key compliance areas. Each one requires specific knowledge, systems, and controls.

Understanding these areas helps you identify where your business has obligations and what measures you need to implement.

Fatigue Management

Fatigue management protects drivers from working excessive hours without adequate rest. Driver fatigue is a leading cause of heavy vehicle crashes.

The HVNL establishes three fatigue management schemes. Standard Hours apply to most drivers and set maximum work times and minimum rest breaks. basic fatigue management (BFM) allows some flexibility with accreditation. Advanced Fatigue Management (AFM) provides the most flexibility for sophisticated operators.

Schedulers must ensure delivery timeframes allow drivers to comply with work and rest requirements. Build buffer time into schedules for delays, traffic, and mandatory breaks.

Use Electronic Work Diaries or written work diaries to record driver hours accurately. These records provide evidence of compliance and help identify fatigue risks.

Monitor schedule compliance and adjust unrealistic timeframes. If drivers consistently report they can’t meet deadlines without speeding or skipping breaks, your schedules need revision.

Mass Management

Mass management ensures vehicles don’t exceed legal weight limits. Overweight vehicles damage roads, are harder to control, and take longer to stop.

Know the maximum weights for vehicles in your operations. These include axle group limits, bridge limits, and Gross Vehicle Mass or Gross Combination Mass.

Implement systems to verify load weights before vehicles depart. This might include weighbridge procedures, load calculation systems, or on-board weighing technology.

Communicate weight limits clearly to loaders and schedulers. Everyone involved in determining what goes on vehicles needs to understand the constraints.

For consignors, provide accurate weights to transport operators. Don’t understate weights. This leads operators to unknowingly breach mass limits.

Load Restraint

Load restraint prevents freight from moving during transport. Poorly restrained loads shift under braking or cornering, causing vehicles to become unstable.

The Load Restraint Guide provides detailed requirements for different freight types. It’s the primary reference for compliance.

Loads must be restrained to prevent movement in all directions during normal driving conditions. This includes acceleration, braking, cornering, and uneven road surfaces.

Use appropriate restraint equipment rated for the loads being secured. Chains, straps, and other equipment must have adequate working load limits.

Train staff who load vehicles in proper restraint techniques. Loading isn’t intuitive. People need specific instruction on weight distribution, restraint patterns, and equipment use.

Vehicle Standards and Maintenance

Vehicle standards ensure heavy vehicles are roadworthy and safe to operate. This covers everything from brakes to lights to steering systems.

Operators must maintain vehicles according to manufacturer specifications and regulatory requirements. Implement scheduled maintenance programs that address all critical systems.

Conduct pre-start checks before every trip. Drivers should inspect vehicles for obvious defects and report any concerns.

Establish clear procedures for taking vehicles out of service when defects arise. Continue operating unsafe vehicles violates CoR obligations and creates serious risks.

Keep maintenance records demonstrating that vehicles receive regular servicing. These records provide evidence of your reasonable steps to maintain vehicle standards.

Speed Management

Speed compliance extends beyond drivers to anyone who influences speed decisions. Unrealistic schedules that require speeding make schedulers liable.

Build realistic timeframes into delivery schedules. Factor in distance, route characteristics, speed limits, traffic conditions, and rest requirements.

Consider using telematics systems that monitor vehicle speeds. This data helps identify compliance issues and provides evidence of speed management efforts.

When drivers report they must speed to meet schedules, investigate and adjust timeframes. Consistent feedback about unrealistic deadlines indicates systemic problems.

For operators, establish clear policies prohibiting speeding and consequences for non-compliance. Drivers need to know that safety takes precedence over delivery times.

Scheduler Responsibilities Under CoR

Schedulers hold significant influence over transport safety. Your decisions about when, where, and how freight moves directly affect driver compliance with the HVNL.

The scheduler party function applies to anyone who controls or influences driver work and rest times. This often includes logistics coordinators, planners, customer service staff, and operations managers.

Schedulers commonly face the most complex CoR obligations because their decisions impact multiple compliance areas simultaneously.

Core Scheduling Obligations

Your primary obligation as a scheduler is ensuring drivers can comply with HVNL requirements. This means realistic timeframes that account for all relevant factors.

Calculate travel times based on actual distances and applicable speed limits. Don’t use average speeds that assume drivers will exceed limits.

Account for loading and unloading times in schedules. Drivers can’t control how long receivers take to unload. Buffer time prevents schedule pressure.

Factor in mandatory rest breaks based on the applicable fatigue management scheme. Drivers working under Standard Hours need specific rest breaks after maximum work periods.

Consider traffic conditions for the planned route and time of day. Urban deliveries during peak hours take longer than the same journey at night.

Allow buffer time for unexpected delays. Weather, road conditions, traffic incidents, and mechanical issues can all affect journey times.

Practical Scheduling Systems

Effective scheduling requires systems that build compliance into the planning process.

Use scheduling software that incorporates HVNL requirements. Modern transport management systems can flag non-compliant schedules before dispatch.

Maintain accurate data on route times, customer service times, and typical delays. This historical information helps create realistic schedules.

Establish clear procedures for schedule changes and urgent deliveries. When customers request expedited service, assess whether it’s achievable without breaching HVNL requirements.

Create feedback loops with drivers about schedule achievability. Drivers know what works in practice. Regular input helps improve schedule accuracy.

Document your scheduling methodology and the factors you consider. This evidence demonstrates your reasonable steps to meet scheduling obligations.

Common Scheduler Traps

Several common situations create CoR risks for schedulers. Awareness helps you avoid these traps.

Customer-driven tight timeframes present frequent challenges. When customers demand specific delivery windows, assess whether they’re realistic given distance and HVNL requirements. Push back when necessary.

Back-to-back deliveries without buffer time create schedule pressure that compounds throughout the day. One delay cascades into all subsequent deliveries.

Failing to account for fatigue history creates risk. A driver who already worked significant hours needs different scheduling than a well-rested driver.

Scheduling based on ideal conditions rather than realistic expectations leads to systematic non-compliance. Your schedules should work in normal conditions, not just perfect ones.

Safety Management Systems (SMS)

A Safety Management System (SMS) is a structured approach to managing transport safety risks. It integrates policies, procedures, and processes into a coherent framework.

Previously, implementing an SMS was considered best practice but not legally mandated. The 2026 HVNL amendments change this by making SMS a legal requirement for CoR parties.

An effective SMS demonstrates your commitment to meeting CoR obligations. It also provides the documented evidence needed to establish a reasonable steps defense.

SMS Core Components

A robust SMS includes several essential elements working together to manage transport safety.

Start with a safety policy that establishes your organization’s commitment to transport safety. This policy should be endorsed by senior management and communicated throughout the organization.

Conduct risk assessments to identify hazards in your transport activities. Assess the likelihood and potential consequences of each risk.

Implement control measures based on the hierarchy of control. Document what controls you’ve selected and why they’re appropriate for the identified risks.

Establish clear procedures for key transport activities. These might cover scheduling, loading, vehicle inspections, incident reporting, and corrective actions.

Provide training to everyone involved in transport activities. Staff need to understand their CoR obligations and how to perform their roles safely.

Monitor compliance through audits, inspections, and performance metrics. Regular verification ensures your SMS operates as intended.

Review and improve your SMS based on monitoring results, incidents, and changes in operations. Continuous improvement keeps your system effective.

Implementing an SMS

Building an SMS from scratch can seem overwhelming. A structured approach makes the task manageable.

Begin by documenting your current transport activities and identifying CoR party functions your organization holds. Understand what you do before assessing risks.

Conduct comprehensive risk assessments for each identified party function. Consider what could go wrong and what harm might result.

Develop procedures addressing identified risks. Start with your highest risks and most significant exposures.

Create a training program covering CoR obligations and your SMS procedures. Everyone involved in transport needs appropriate knowledge.

Establish monitoring and audit processes. Determine how you’ll verify that procedures are followed and controls are effective.

Document everything. Your SMS must be written, accessible, and implemented. Unwritten policies and informal practices don’t satisfy HVNL requirements.

Consider seeking expert assistance. CoR compliance consultants can help design SMS frameworks tailored to your operations and industry.

CoR Penalties and Enforcement

The HVNR enforces CoR through a range of penalties. Understanding potential consequences helps motivate proper compliance.

Penalties vary based on the offense type, the party involved, and whether the breach is a first offense or repeat violation.

Penalty Structure

The HVNL establishes three penalty tiers: minor, substantial, and severe.

Minor risk breaches involve lower-risk violations. These attract smaller penalties but still represent legal breaches.

Substantial risk breaches involve actions that create significant safety risks. Penalties increase substantially for these violations.

Severe risk breaches involve the most serious violations with greatest potential harm. Maximum penalties apply to these offenses.

Corporate entities face much higher maximum penalties than individuals. A severe risk breach can attract up to $3 million in penalties for a corporation.

| Breach Category | Risk Level | Potential Consequences |

|---|---|---|

| Minor Risk | Lower safety impact | Warnings, infringement notices, lower-tier penalties |

| Substantial Risk | Significant safety impact | Court prosecution, mid-tier penalties, possible director liability |

| Severe Risk | Critical safety impact | Serious prosecution, maximum penalties, executive liability |

Enforcement Approach

The NHVR uses a graduated enforcement approach. They escalate responses based on breach severity and compliance history.

Education comes first for parties making good-faith efforts to comply. The NHVR provides guidance and allows time for corrective action.

Warnings apply when breaches are identified but circumstances suggest education will achieve compliance. Warnings create formal records but don’t involve penalties.

Infringement notices are issued for clear breaches where formal penalties are warranted but prosecution isn’t necessary. These carry financial penalties but avoid court proceedings.

Prosecution occurs for serious breaches, repeat violations, or where parties show disregard for their obligations. Court proceedings can result in maximum penalties plus legal costs.

The NHVR considers several factors when determining enforcement responses. These include breach severity, actual or potential harm, compliance history, cooperation with investigators, and demonstrated corrective actions.

The Reasonable Steps Defense

The HVNL provides a defense if you can demonstrate you took reasonable steps to prevent the breach. This defense is critical for CoR parties.

To establish the defense, you must show that you took all reasonable steps available to prevent the offense. Partial efforts aren’t sufficient.

Documentation is essential. You need evidence showing what steps you took, when you took them, and why they were appropriate for the risks.

Your SMS provides much of this evidence. Documented procedures, training records, audit results, and risk assessments all support reasonable steps claims.

Act before breaches occur. Implementing controls after an incident doesn’t help establish reasonable steps for that breach.

Consignor and Loader Obligations

Consignors and loaders hold specific obligations related to freight preparation and vehicle loading. These roles directly influence mass, dimension, and load restraint compliance.

The consignor party function applies to anyone who consigns goods for transport. This typically includes shippers, manufacturers, wholesalers, and retailers arranging freight movement.

Loader responsibilities fall on anyone who loads goods onto vehicles. This might include warehouse staff, forklift operators, or third-party loading services.

Consignor Responsibilities

Consignors must ensure they don’t cause or contribute to transport breaches. This extends across multiple areas.

Provide accurate information about freight characteristics. This includes weights, dimensions, and any special handling requirements.

Ensure loads are packaged appropriately for transport. Packaging must protect goods while allowing proper restraint.

Communicate clearly with transport operators about loading requirements and timeframes. Realistic expectations prevent pressure that leads to rushed, unsafe loading.

Consider how your consignment decisions affect transport safety. Specifying particular carriers or delivery times can create risks if those requirements are unrealistic.

Document your communications with transport operators. Records of weight declarations and loading instructions provide evidence of your reasonable steps.

Loader Duties

Loaders must ensure vehicles are loaded safely and legally. This means managing weight, distribution, and restraint.

Verify load weights stay within vehicle limits. Use weighbridge certificates, load calculations, or on-board weighing to confirm compliance before vehicles depart.

Distribute weight appropriately across axle groups. Poor weight distribution can overload individual axles even when total mass is legal.

Restrain loads according to Load Restraint Guide requirements. Select appropriate equipment and use proper restraint patterns for the freight type.

Ensure loads are stable and secure. Test restraint before allowing vehicles to depart by applying manual force to check for movement.

Refuse to load vehicles that are unsuitable or unsafe. If a vehicle is defective or lacks proper restraint equipment, don’t load it.

Loading Manager Oversight

Loading managers supervise loading operations and establish loading procedures. Your role involves ensuring safe loading practices across your facility.

Develop documented loading procedures covering all freight types handled. These procedures should specify weight verification, distribution requirements, and restraint methods.

Train loading staff in proper techniques. Provide initial training for new staff and regular refresher training for experienced workers.

Supply appropriate loading equipment and restraint materials. Staff need the right tools to load vehicles safely.

Monitor loading practices through inspections and audits. Regular verification ensures procedures are followed consistently.

Investigate incidents where loads shift during transport. Understanding what went wrong helps prevent future failures.

Risk Management and Compliance Audits

Effective risk management and regular audits form the backbone of CoR compliance. These processes help identify problems before they cause breaches or incidents.

Risk management involves systematically identifying hazards, assessing risks, and implementing controls. It’s a continuous cycle, not a one-time activity.

Conducting Transport Risk Assessments

Transport risk assessments identify what could go wrong in your operations and how serious the consequences might be.

Start by mapping your transport activities. Document the full process from order placement through delivery.

Identify hazards at each stage. Consider what could lead to HVNL breaches or safety incidents. Don’t limit assessment to obvious risks.

Assess likelihood and consequence for each identified risk. Use a simple matrix to categorize risks as low, medium, or high.

Determine existing controls already in place. What are you currently doing to manage each risk?

Evaluate whether existing controls are adequate. Consider whether additional or alternative measures would better manage the risk.

Prioritize risks for action. Address highest risks first, then work through medium and low risks.

Document your assessment process and findings. Risk assessment records provide evidence of your systematic approach to safety management.

Compliance Audit Programs

Regular audits verify that your CoR systems work as intended. Audits identify gaps between documented procedures and actual practices.

Internal audits use your own staff to review compliance. These provide frequent verification at lower cost than external audits.

External audits engage independent experts to assess your systems. Third-party audits provide objective verification and identify issues internal reviews might miss.

Schedule audits regularly. Annual comprehensive audits supplemented by quarterly focused audits on high-risk areas work well for most operations.

Audit against your SMS procedures, HVNL requirements, and relevant codes of practice. Compare actual practices to requirements.

Document audit findings including both compliant practices and non-conformances. Comprehensive records track improvement over time.

Implement corrective actions for identified issues. Audits only add value if findings lead to improvements.

Continuous Improvement

CoR compliance requires ongoing attention and improvement. Static systems become outdated as operations change.

Review your SMS annually at minimum. Consider whether procedures remain appropriate for current operations.

Update risk assessments when operations change. New products, routes, vehicles, or customers may introduce different risks.

Analyze incidents and near-misses for lessons. Every incident provides information about system weaknesses.

Monitor industry developments and regulatory changes. Stay informed about new requirements and emerging best practices.

Benchmark against industry peers where possible. Understanding how similar operations manage CoR helps identify improvement opportunities.

NHVAS Accreditation

The National Heavy Vehicle Accreditation Scheme (NHVAS) provides a framework for demonstrating systematic safety management. Accreditation offers benefits beyond basic compliance.

NHVAS includes several modules covering different aspects of heavy vehicle operations. Mass management, maintenance management, and basic fatigue management are common options.

Accredited operators can access regulatory concessions. These might include higher mass limits, extended operating hours, or reduced administrative requirements.

Accreditation Benefits

NHVAS accreditation demonstrates your commitment to systematic safety management. This provides several advantages.

Regulatory recognition shows you’ve implemented systems meeting national standards. This evidence supports reasonable steps defenses.

Operational benefits include access to concessions and reduced compliance burden. Accredited operators often face less frequent roadside inspections.

Commercial advantages emerge from demonstrating safety credentials. Major customers increasingly require suppliers hold relevant accreditation.

Insurance considerations may improve with accreditation. Some insurers offer better rates for accredited operators.

Continuous improvement culture develops through the accreditation process. The systems required for NHVAS create structured approaches to ongoing enhancement.

Pursuing Accreditation

Achieving NHVAS accreditation requires developing systems meeting scheme standards. The process involves several stages.

Select relevant modules based on your operations. Not all modules apply to every business. Focus on areas where you have exposure.

Develop systems and procedures meeting module requirements. Each module has specific standards your systems must address.

Implement procedures and train staff. Systems must be operational, not just documented.

Conduct internal audits to verify system effectiveness. Identify and correct any gaps before applying for accreditation.

Submit your application and undergo assessment. An approved auditor will review your systems against module standards.

Maintain your systems and undergo regular reassessment. Accreditation requires ongoing demonstration of system operation.

Moving Forward with Chain of Responsibility

Chain of Responsibility compliance protects your business, your people, and the broader community. The obligations are significant, but manageable with proper systems.

Start by identifying which CoR party functions apply to your operations. Understanding who is a duty holder under HVNL clarifies your obligations.

Conduct risk assessments for each party function you hold. Know what can go wrong before implementing controls.

Develop documented procedures addressing identified risks. Your SMS provides the framework for systematic compliance. Implementing Chain of Responsibility requires structured approaches tailored to your operations.

Train everyone involved in transport activities. Knowledge of obligations and procedures enables people to work safely.

Monitor your systems through regular audits and performance reviews. Verification ensures procedures are followed.

The 2026 HVNL amendments increase expectations for all CoR parties. Understanding the upcoming regulatory changes helps you prepare for new requirements.

Consider seeking expert assistance to develop or review your systems. Compliance specialists provide objective assessment and industry insights.

For executives, meet your due diligence obligations through active oversight and documented involvement. Understanding why Chain of Responsibility matters motivates appropriate attention at leadership levels.

Remember that CoR compliance is ongoing, not a one-time project. Regular review and continuous improvement keep your systems effective as operations evolve.

The investment in proper CoR compliance systems pays dividends through reduced risk exposure, demonstrated professionalism, and genuine safety improvements. Start now, work systematically, and build compliance into your business operations.