Safety management systems consistently fail when organizations treat implementation as a compliance project rather than a cultural transformation. The most damaging issues stem from disconnects between documented procedures and actual workplace behavior, inadequate leadership visibility in safety activities, and data systems that overwhelm rather than inform decision-making. These challenges compound rapidly because they reinforce each other, creating systemic weaknesses that regulatory audits miss entirely but workplace incidents expose dramatically.

Most businesses underestimate the sustained investment required. Implementation guidance notes that organizations often underestimate the staff time, technology investment, and specialist expertise needed to implement and sustain an SMS. The gap between strategic safety commitments and operational reality becomes a breeding ground for incidents.

What follows addresses the eight most critical safety management system issues that undermine workplace safety. Each challenge includes practical strategies drawn from regulatory frameworks and operational experience across diverse industries. Understanding these obstacles helps organizations move beyond checkbox compliance toward genuine risk reduction.

1. Leadership Commitment Failures That Cascade Through Operations

Senior management often signs safety policies but rarely demonstrates visible, consistent commitment to safety priorities. This disconnect becomes immediately apparent to frontline workers who see safety initiatives announced but never resourced, safety concerns raised but never addressed, and safety metrics reported but never acted upon.

Leadership support, supervision, and enforcement of procedures are among the strongest determinants of effective safety implementation. When executives skip safety meetings, override safety decisions for production reasons, or delegate all safety responsibilities without maintaining oversight, they signal that safety is subordinate to other business objectives.

Accountability Structure Weaknesses

Many organizations lack clear accountability mechanisms that connect safety performance to management evaluation and advancement. Safety responsibilities become diffused across multiple roles without single-point accountability. Line managers receive safety duties without corresponding authority or resources to fulfill them.

Establish executive safety performance indicators that appear in business reviews. Assign specific safety deliverables to each senior leader with quarterly public reporting. Include safety performance as a weighted factor in management compensation and promotion decisions. Create visible consequences for safety commitment gaps.

Resource Allocation Patterns That Reveal Priorities

Budget discussions expose true organizational priorities. When safety department requests receive consistent deferrals while other initiatives gain immediate approval, the workforce notices. When safety training gets cancelled for production demands but sales training never does, the message is clear.

Conduct annual safety budget reviews that compare safety investment to other corporate functions. Calculate safety spending as a percentage of revenue. Benchmark against industry standards and regulatory expectations. Present findings to the board with gap analysis and risk implications.

2. Employee Engagement Deficits That Silence Critical Intelligence

Workforce disengagement from safety management systems creates the most dangerous blind spots. Employees who see safety as something done to them rather than with them withhold crucial information about hazards, near-misses, and system failures. This intelligence vacuum leaves management making decisions based on incomplete or outdated operational understanding.

Traditional top-down safety management approaches fail because frontline workers possess the most detailed knowledge of actual workplace conditions. When their insights don’t influence safety decisions, they stop sharing them. The safety management system becomes detached from operational reality.

Reporting Barrier Analysis

Many workers fear reporting incidents will trigger blame rather than corrective action. Complex reporting systems require excessive time and effort. Feedback loops fail, so reporters never learn what happened with their concerns. Previous reports that generated no visible response discourage future reporting.

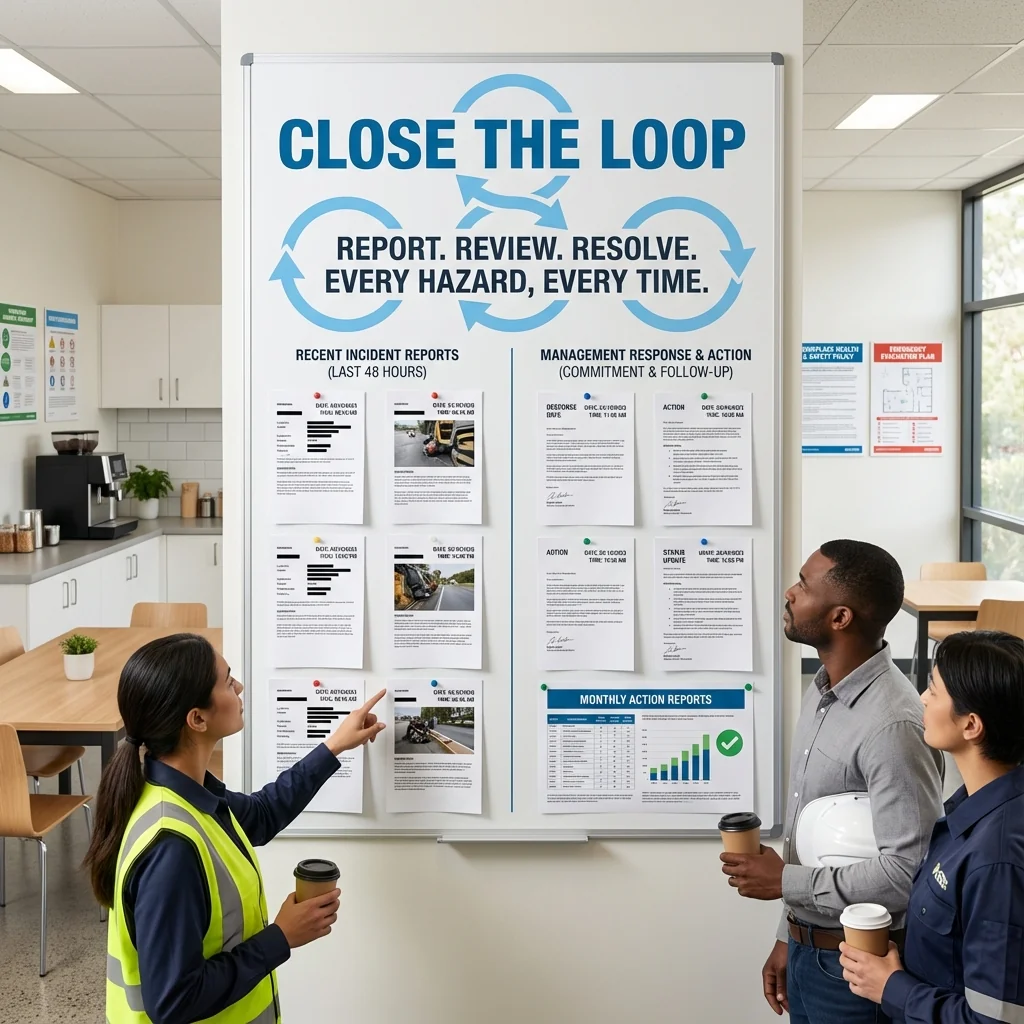

Safety specialists emphasize that a ‘just culture’ is critical to SMS effectiveness. Implement anonymous reporting channels with guaranteed no-retaliation policies. Simplify reporting to two-minute mobile submissions. Create closed-loop communication where every report receives response within 48 hours. Publicize actions taken based on worker reports monthly.

Participation Mechanism Development

Safety committees often include the same individuals year after year, becoming disconnected from broader workforce perspectives. Meeting agendas focus on compliance reporting rather than genuine problem-solving. Recommendations from safety committees receive acknowledgment but not implementation.

Rotate safety committee membership annually with representation from all shifts and departments. Reserve committee agenda time for frontline-identified issues. Require management response with timeline to all committee recommendations within 30 days. Track implementation rates and report them publicly.

3. Compliance-Focused Approaches That Miss Proactive Prevention

Organizations frequently build safety management systems around regulatory compliance minimums rather than actual risk reduction. This creates documentation-heavy processes that satisfy auditors but don’t prevent incidents. The focus shifts to demonstrating compliance rather than achieving safety outcomes.

Compliance-driven safety becomes reactive, addressing hazards only after regulations require it or incidents occur. Proactive identification of emerging risks receives minimal attention. The safety management system becomes an administrative burden rather than a strategic risk management tool.

Risk-Based Priority Setting

Guidance highlights the importance of integrating regulatory compliance into practical SMS processes rather than managing compliance as a separate checklist activity. Organizations need systematic processes to identify, assess, and prioritize risks based on severity and likelihood rather than regulatory visibility.

Develop risk assessment protocols that evaluate potential consequences independent of regulatory requirements. Create risk registers that score hazards by potential harm and exposure frequency. Allocate safety resources based on risk rankings rather than compliance deadlines. Review and update risk assessments quarterly as operations change.

Preventive Control Implementation

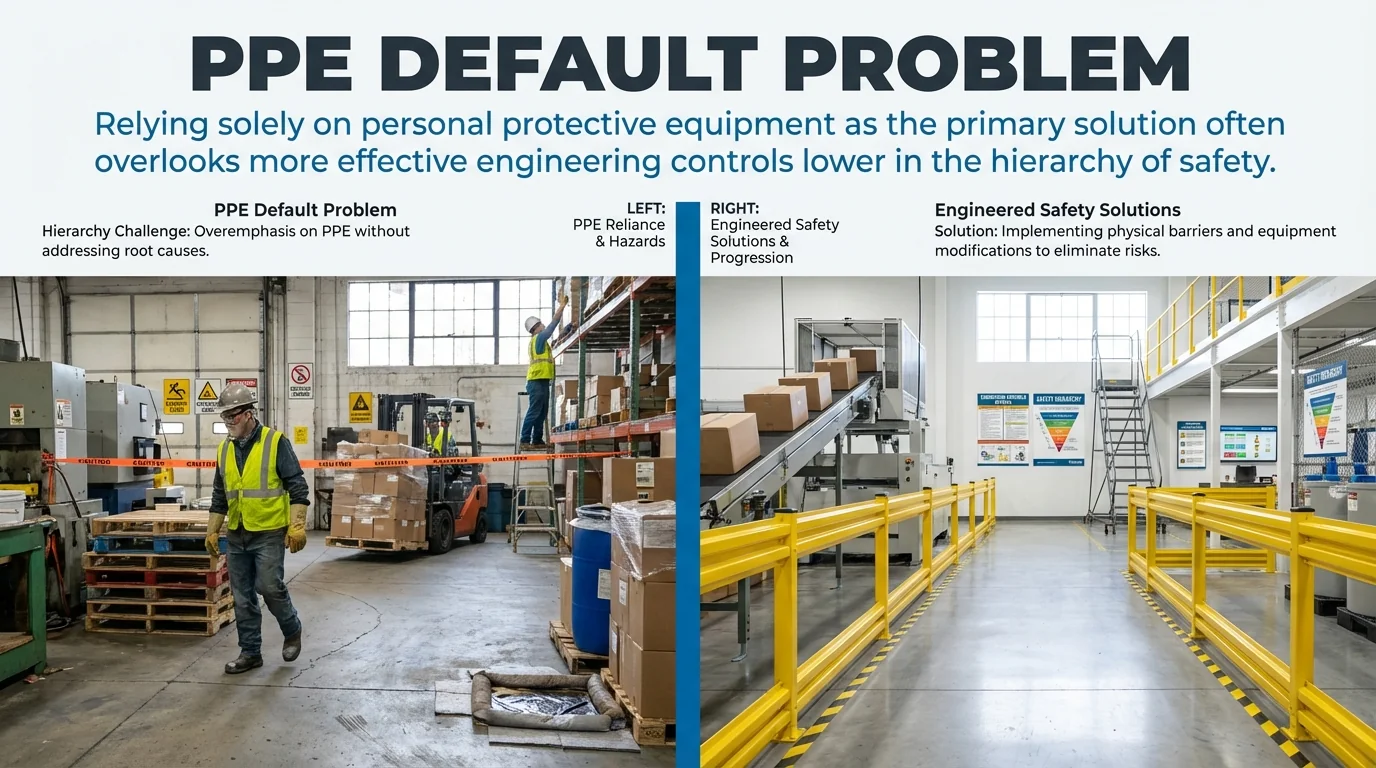

Reliance on personal protective equipment and procedural controls while under-using higher-order controls in the hierarchy of controls is a documented implementation challenge. Organizations default to easier administrative controls rather than engineering solutions that eliminate hazards.

Apply the hierarchy of controls systematically to each identified hazard. Exhaust elimination and substitution options before considering engineering controls. Evaluate engineering controls fully before implementing administrative solutions. Use PPE only as the final layer of protection, never the primary control. Document the decision logic for control selection.

For detailed guidance on building proactive systems, see our article on implementing a safety management system.

4. Data Management Problems That Paralyze Decision-Making

New and experienced safety managers report becoming overwhelmed by the volume and variety of SMS data. Systems generate extensive reports that nobody reads or acts upon. Critical patterns disappear in data noise.

Manual data collection methods create inconsistency and incompleteness. Different departments use incompatible tracking systems. Historical data remains inaccessible in filing cabinets or outdated software. Analysis becomes impossible without integrated, accessible information.

Data Integration Architecture

Build centralized safety data platforms that consolidate incident reports, inspection findings, training records, and corrective action tracking. Implement consistent data standards across all collection points. Ensure mobile accessibility for field data entry. Create automated data quality checks that flag incomplete or inconsistent entries.

Integrate safety data with operational systems to enable correlation analysis between safety metrics and production activities. Connect equipment maintenance records with incident data. Link training completion to job assignments. Enable cross-referencing that reveals systemic patterns.

Analytics Capability Development

Most organizations collect extensive safety data but extract minimal insight. Reports provide historical descriptions without predictive value. Analysis remains superficial, identifying what happened but not why or what might happen next.

Develop leading indicator dashboards that track proactive safety activities alongside lagging incident metrics. Calculate incident rates by department, shift, and job type. Analyze trends over time to identify deteriorating conditions early. Use statistical process control methods to distinguish normal variation from significant changes requiring intervention.

| Data Category | Collection Frequency | Key Metrics | Review Cycle |

|---|---|---|---|

| Incident Reports | Immediate | Frequency, severity, location | Weekly |

| Safety Inspections | Scheduled | Compliance rate, findings | Monthly |

| Training Records | Continuous | Completion rate, competency | Quarterly |

| Corrective Actions | Ongoing | Closure rate, effectiveness | Biweekly |

5. Training Inadequacies That Create Competency Gaps

Safety training often consists of annual presentations that employees passively attend without genuine learning or behavior change. Content remains generic rather than job-specific. Delivery methods fail to engage learners or verify competency.

Organizations provide initial safety training but neglect ongoing competency development as jobs evolve and new hazards emerge. Refresher training becomes checkbox compliance rather than skills reinforcement. Training effectiveness receives no measurement beyond attendance tracking.

Competency-Based Training Design

Replace time-based training requirements with competency-based assessments. Define specific safety competencies required for each role. Develop training modules targeted to job-specific hazards and tasks. Include hands-on practice and skill demonstration rather than lecture-only formats.

Implement pre-training assessment to identify individual knowledge gaps. Customize training content based on assessed needs. Conduct post-training competency verification through practical demonstrations. Require managers to observe and validate safety skills during normal work activities.

Training Resource Infrastructure

In many health-care settings, high workloads and insufficient staffing reduce the real-world impact of safety training and interventions. Organizations must allocate adequate time and resources for meaningful training delivery and practice.

Schedule dedicated training time that doesn’t compete with production demands. Provide backfill staff so training participants can focus without operational pressure. Invest in qualified instructors with subject matter expertise and teaching skills. Develop training materials professionally rather than relying on hastily assembled presentations.

Understanding core elements helps identify where training gaps exist. Review our guide on key components of a safety management system for comprehensive context.

6. Communication Breakdowns That Fragment Safety Culture

Information flows inconsistently across organizational levels and departments. Safety policies exist but remain unknown to those who must follow them. Critical safety updates fail to reach affected workers. Feedback mechanisms don’t function, creating one-way communication that disengages the workforce.

Different departments interpret safety requirements differently, creating inconsistent standards. Shift handovers omit safety-critical information. Contractors receive minimal safety orientation. Language barriers and literacy differences create comprehension gaps that standard communication methods don’t address.

Multi-Channel Communication Systems

Establish redundant communication channels that ensure safety-critical information reaches everyone. Combine written notices, digital platforms, toolbox talks, and visual displays. Translate materials for non-native speakers. Use graphics and symbols for workers with literacy challenges.

Implement structured shift handover protocols that require safety information transfer. Create standard communication templates for different message types. Verify message receipt and understanding through acknowledgment systems. Track communication effectiveness through comprehension spot-checks.

Feedback Loop Completion

Most organizations request safety feedback but fail to close the loop by communicating responses and actions taken. This silence discourages future participation. Workers assume their input was ignored or dismissed.

Create visible response mechanisms for all safety communications. Publish monthly safety action reports showing issues raised and resolution status. Recognize individuals who identified important safety concerns. Explain decisions when suggested actions aren’t implemented. Demonstrate that safety communication generates tangible outcomes.

7. Resource Constraints That Force Impossible Trade-offs

Safety management systems require sustained investment in personnel, technology, training, and equipment. Underfunding creates gaps where documented procedures become impossible to execute. Staff shortages force workers to skip safety steps or accept uncontrolled risks.

Budget limitations push organizations toward minimum compliance rather than effective risk management. Safety equipment receives delayed replacement. Maintenance gets deferred. Training budgets face annual cuts. These resource decisions accumulate until the safety management system exists primarily on paper.

Business Case Development

Quantify the costs of safety deficiencies to build compelling resource justifications. Calculate direct costs from incidents including medical expenses, equipment damage, and lost production. Add indirect costs such as investigation time, replacement worker training, and regulatory penalties. Include insurance premium impacts and potential legal exposure.

Compare total risk costs against proposed safety investments. Demonstrate return on investment from risk reduction. Present safety resource needs alongside other capital requests with equivalent financial justification. Frame safety investment as risk management rather than compliance expense.

Efficiency Optimization

Maximize impact from available resources through strategic allocation and process efficiency. Identify high-risk activities where focused investment delivers greatest risk reduction. Eliminate redundant safety activities that consume resources without adding value. Automate administrative tasks to free personnel for higher-value work.

Leverage technology to extend resource capacity. Use mobile applications to streamline inspections and reporting. Implement online training for knowledge transfer, reserving instructor time for skills practice. Deploy monitoring systems that provide continuous oversight without constant human presence.

Effective resource allocation requires the right tools. Explore our overview of essential tools for an effective safety management system.

8. Implementation Gaps Between Strategy and Execution

Research on Safe System and Vision Zero approaches identifies implementation gaps where high-level strategies exist but are not consistently translated into concrete, local actions. Corporate safety policies read impressively but provide insufficient guidance for frontline application.

Strategic safety goals remain abstract without operational translation. Procedures describe what to do but not how to do it in specific work contexts. Implementation responsibility gets assigned without corresponding authority, resources, or accountability. Pilot programs succeed but never scale across the organization.

Operational Translation Process

Convert strategic safety objectives into specific, measurable actions for each organizational level. Define what corporate safety goals mean for individual departments, supervisors, and workers. Create implementation guides that address job-specific applications. Include decision trees and examples that clarify ambiguous situations.

Engage frontline workers in translating procedures into practical application. Conduct walkthrough exercises where workers demonstrate how they’ll apply new requirements. Identify barriers to implementation before rollout. Adjust procedures based on operational feedback to ensure feasibility.

Change Management Infrastructure

Treat safety management system implementation as organizational change requiring structured change management. Identify stakeholders at all levels and address their specific concerns. Provide implementation support beyond initial announcement. Monitor adoption and intervene when implementation stalls.

Establish project management discipline for safety initiatives. Define clear milestones with assigned owners and deadlines. Track progress against implementation plans. Conduct post-implementation reviews to identify lessons learned. Build continuous improvement into the safety management system design.

Evidence from low- and middle-income countries indicates that weak enforcement of safety policies and limited resources can negate the positive impact of worker knowledge or motivation on safety performance. Implementation requires consistent follow-through, not just policy creation.

| Implementation Phase | Key Activities | Common Failures | Success Factors |

|---|---|---|---|

| Planning | Gap assessment, resource allocation | Inadequate scoping | Stakeholder involvement |

| Rollout | Training, procedure distribution | Rushed deployment | Phased implementation |

| Adoption | Monitoring, support provision | Insufficient follow-up | Active management presence |

| Sustainment | Reinforcement, improvement | Attention drift | Ongoing accountability |

Building Sustainable Safety Management Capability

Addressing safety management system issues requires systematic, sustained effort across multiple organizational dimensions. No single intervention fixes systemic problems. Success requires leadership commitment, workforce engagement, adequate resources, and persistent implementation discipline.

Start by conducting a thorough gap assessment against the eight challenge areas outlined above. Prioritize issues based on risk exposure and implementation feasibility. Develop a multi-year improvement roadmap with specific milestones and accountability. Allocate dedicated resources to drive implementation rather than adding to existing workloads.

Measure progress through both leading indicators of safety system health and lagging indicators of safety outcomes. Leading indicators include training completion rates, inspection findings closure rates, near-miss reporting frequency, and corrective action effectiveness. These predict future performance rather than just documenting past failures.

Remember that safety management systems exist to reduce risk and prevent harm, not to create bureaucracy. Every procedure, report, and meeting should contribute directly to those objectives. Regularly review safety processes to eliminate activities that consume resources without adding value. Focus effort where it generates genuine risk reduction.

The most effective safety management systems embed safety into normal business operations rather than maintaining it as a separate compliance function. Safety considerations integrate into operational decisions, budgeting processes, performance evaluations, and strategic planning. When safety becomes how the organization works rather than additional work, sustainable improvement becomes possible.

Organizations that successfully navigate these challenges transform their safety culture and performance. They move beyond compliance minimums to create workplaces where incidents become rare rather than routine. This transformation requires commitment, resources, and patience, but the alternative carries unacceptable risk to people and business continuity.