Transport safety hazards claim lives and disrupt operations across every mode of transport. The World Health Organization estimates approximately 1.19 million people die in road crashes globally each year. These aren’t just statistics. They represent preventable incidents that destroy families, cripple businesses, and strain entire supply chains.

The transportation industry faces persistent safety challenges spanning driver behavior, vehicle integrity, cargo management, and environmental conditions. Understanding these hazards isn’t about satisfying regulatory obligations. It’s about building resilient operations that protect people and deliver consistent service.

This guide examines seven critical transportation safety issues affecting road, rail, air, and maritime operations. Each section provides the context you need to recognize hazards, understand their operational impact, and implement control measures that actually work in daily operations. You’ll find evidence-based approaches drawn from regulatory frameworks, industry research, and practical compliance strategies.

Transport safety management requires systematic thinking. The following sections build on each other, moving from individual operator risks through vehicle and cargo considerations to broader environmental factors. Whether you manage a single delivery van or a national fleet, these hazards demand attention in your safety systems.

1. Driver Fatigue and Drowsy Driving

Driver fatigue degrades reaction times, impairs judgment, and increases crash risk across all transport modes. It’s a systemic safety hazard with clear physiological roots and measurable consequences.

Fatigue occurs when drivers operate vehicles without adequate rest. The human body requires consistent sleep cycles. When drivers work extended hours, irregular shifts, or face tight delivery schedules, their cognitive performance deteriorates. Reaction times slow. Decision-making suffers. Microsleeps become dangerous.

The transportation industry’s operational demands often conflict with human biology. Long-haul truck drivers face pressure to maximize driving time. Shift workers in logistics experience circadian rhythm disruption. Delivery drivers encounter unpredictable schedules that prevent consistent rest patterns.

Regulatory Controls and Work Hour Limits

Australian Heavy Vehicle National Law establishes specific work and rest hour requirements. Standard hours allow 12 hours work in 24 hours, with mandatory rest breaks. Basic Fatigue Management and Advanced Fatigue Management provide flexibility for operators who implement robust fatigue management systems.

These regulations exist because enforcement alone cannot eliminate fatigue. Operators must design schedules that prioritize adequate rest. Route planning should account for realistic driving times. Delivery windows need buffer time that doesn’t force drivers to choose between compliance and job security.

Operational Prevention Strategies

Effective fatigue management starts with schedule design. Build rosters that provide consistent sleep opportunities. Avoid back-to-back shifts that cross day and night periods. Plan routes with designated rest stop locations.

Implement monitoring systems that track actual hours worked, not just scheduled hours. Many drivers extend their workday with pre-trip inspections, loading activities, and administrative tasks. These hidden hours accumulate into fatigue risk.

Training programs should educate drivers about recognizing fatigue symptoms in themselves. Empower them to stop driving when impaired. Create a safety culture where reporting fatigue doesn’t trigger punishment.

Technology solutions like in-cab monitoring systems can detect drowsiness indicators. However, technology supplements rather than replaces proper scheduling and organizational culture. No sensor prevents fatigue as effectively as adequate rest.

2. Distracted Driving and Mobile Device Use

With fatigue management establishing the foundation of driver safety, distracted driving represents another critical behavioral hazard. Distraction diverts cognitive resources from the primary task of vehicle operation.

Mobile phone use stands as the most prevalent distraction source. Drivers text, check emails, use navigation apps, and take calls while controlling multi-tonne vehicles. Each glance at a screen removes attention from road conditions, traffic movements, and potential hazards.

The problem extends beyond handheld devices. Infotainment systems, dispatch communications, electronic logging devices, and fleet management tablets all compete for driver attention. Even hands-free technology creates cognitive load that degrades driving performance.

The True Cost of Split-Second Distractions

Vehicle collisions caused by distracted driving often involve rear-end impacts, lane departures, and intersection incidents. A driver traveling 100 kilometers per hour covers 28 meters per second. Three seconds of distraction means traveling 84 meters without visual attention to the road.

Control Measures Beyond Policy Statements

Written policies prohibiting mobile phone use provide legal protection but limited practical effect. Enforcement requires observable evidence and consistent consequences.

Implement technology controls that limit device functionality while vehicles operate. Fleet management systems can disable non-essential apps during trips. Some devices automatically route incoming calls to voicemail when motion sensors detect driving.

Schedule design influences distraction temptation. Drivers feeling rushed to meet unrealistic delivery windows take calls while driving. Build schedule buffers that allow drivers to pull over safely for communications.

Training should address all distraction sources, not just phones. Eating, adjusting climate controls, reaching for objects, and even conversation create cognitive load. Teach drivers to complete adjustments before moving and to pull over when attention demands arise.

3. Vehicle Collisions and Traffic Crashes

Understanding driver behavior hazards leads directly to their most visible consequence. Vehicle collisions represent the intersection of multiple risk factors manifesting in property damage, injuries, and fatalities.

In Australia, 1,361 road deaths occurred in the 12 months ending October 2025, representing a 6.9% increase compared with the previous 12 months. Each collision stems from a chain of contributing factors rather than a single cause.

Common Collision Types and Contributing Factors

Rear-end collisions frequently involve following distances insufficient for stopping. Drivers underestimate their vehicle’s stopping distance, particularly when operating heavy vehicles with loaded cargo. Weather conditions, road surface, and brake system condition all affect stopping capability.

Intersection crashes occur when drivers fail to yield right of way, misjudge gaps in traffic, or run red lights. Speed compounds these errors. Higher speeds reduce the time available for hazard recognition and increase impact severity.

Single-vehicle crashes often involve lane departures. Fatigue, distraction, impairment, or poor road conditions cause drivers to leave their lane. Collisions with fixed objects, rollovers, and run-off-road incidents follow.

Head-on collisions, while less frequent, produce the highest fatality rates. Overtaking maneuvers on undivided roads, wrong-way entry, and median crossovers create these devastating crashes.

Speed Management as Crash Prevention

Speed influences both crash likelihood and severity. Higher speeds reduce available reaction time. They increase stopping distances exponentially. Impact energy rises with the square of velocity.

Speed limits reflect road design, traffic mix, and adjacent land use. Operators should implement fleet speed limiters below posted limits when risk assessment justifies restrictions. Urban delivery vehicles rarely need highway speeds.

Telematics systems that monitor speed provide valuable data for coaching. Identify drivers who consistently exceed limits. Investigate whether route scheduling creates pressure to speed. Address systemic causes alongside individual behavior.

Defensive Driving Programs

Driver safety training should emphasize hazard anticipation over reaction skills. Teach drivers to scan intersections before entering. Train them to identify vehicles exhibiting erratic behavior. Develop their ability to recognize potential conflicts before they become emergencies.

Defensive driving includes maintaining safe following distances, positioning vehicles for maximum visibility, and creating escape routes. These proactive strategies reduce collision risk more effectively than emergency maneuver training.

Our systematic approach to transport safety challenges emphasizes embedding these practices into daily operations rather than treating them as isolated training events.

4. Poor Vehicle Maintenance and Equipment Failure

Moving from driver-related factors to vehicle integrity issues, inadequate maintenance creates predictable safety hazards. Mechanical failures don’t occur randomly. They result from deferred maintenance, inadequate inspection, and failure to address known defects.

Brake system failures represent the most critical maintenance-related hazard. Heavy vehicles depend on properly functioning air brake systems. Worn brake pads, contaminated brake fluid, air leaks, and damaged components all degrade braking performance.

Tire failures cause loss of control, particularly at highway speeds. Worn tread reduces traction in wet conditions. Under-inflation generates excessive heat. Damaged sidewalls rupture under load. Regular tire inspection and pressure monitoring prevent most tire-related incidents.

Critical Safety Systems Requiring Regular Inspection

Steering systems must maintain precise control. Worn tie rod ends, damaged power steering components, and loose steering linkages create dangerous play in steering response. Drivers may not recognize gradual degradation until failure occurs.

Lighting and visibility systems ensure other road users can see your vehicle and drivers can see the road. Burned-out headlights, broken turn signals, obscured mirrors, and damaged windscreens compromise safety. These seem minor until darkness or weather reduces visibility.

Load securing equipment prevents cargo from shifting or detaching. Damaged tie-down points, worn straps, and broken chains create load securement failures. The cargo becomes a projectile hazard.

Implementing Systematic Maintenance Programs

Schedule preventive maintenance based on manufacturer specifications and operating conditions. Harsh environments, heavy loads, and intensive use accelerate component wear. Your maintenance intervals should reflect actual operating conditions, not generic recommendations.

Pre-trip inspections by drivers identify defects before they cause crashes. However, driver inspections only work when drivers receive proper training, have adequate time, and understand that reporting defects won’t result in punishment. Many drivers face pressure to overlook defects to maintain schedules.

Maintain detailed maintenance records for each vehicle. Track recurring issues that indicate systemic problems. A vehicle requiring frequent brake repairs needs investigation beyond component replacement. Design flaws, operator behavior, or operational demands may be contributing factors.

Establish clear defect reporting and vehicle grounding procedures. Define which defects require immediate vehicle removal from service. Ensure drivers know how to report defects without fear of schedule pressure overriding safety decisions.

5. Improper Cargo Loading and Securement

Vehicle integrity depends not just on mechanical condition but also on proper cargo management. With maintenance systems ensuring vehicle components function correctly, cargo handling and securement become the next critical control point.

Improperly loaded cargo creates multiple hazards. Unbalanced loads affect vehicle stability. Forward-positioned loads reduce rear axle traction. Rear-heavy loads cause front axle lift. Side-loaded cargo increases rollover risk during turns.

Unsecured cargo can shift during normal driving maneuvers. Braking causes forward movement. Cornering creates lateral forces. Acceleration shifts loads rearward. Each movement affects vehicle handling and can cause loss of control.

Load Securement Requirements

Australian load restraint regulations require cargo to withstand specific force levels in all directions. Loads must resist 80% of their weight forward, 50% rearward, and 50% laterally. These aren’t arbitrary numbers. They reflect actual forces during emergency maneuvers.

Securement methods depend on cargo type. Tie-down straps work for rigid loads. Blocking and bracing prevent movement of stackable cargo. Friction-based securement requires sufficient contact area and appropriate surface materials.

Calculate required restraint based on cargo weight and chosen restraint method. Each tie-down strap has a rated working load limit. Using inadequate restraints creates predictable failure. Chain of Responsibility obligations extend to all parties in the transport chain, including those who load and schedule vehicles.

Weight Distribution and Axle Loading

Proper load placement maintains vehicle stability and ensures legal axle weights. Exceeding axle weight limits damages road infrastructure and increases crash severity. It also indicates improperly distributed cargo that affects handling.

Load cargo to maintain manufacturer-specified weight distribution. Position heavy items low and centered. Distribute weight to keep axle loads within limits. Use onboard weighing systems or weigh bridges to verify compliance before departure.

Loading Process Controls

Loading areas should provide adequate lighting, level surfaces, and proper equipment. Rushed loading in poor conditions creates predictable errors. Forklifts require trained operators and regular maintenance.

Loading procedures should specify cargo placement, restraint requirements, and inspection checkpoints. Document these procedures and train all personnel involved in loading operations. Loading isn’t a driver-only responsibility.

Drivers should inspect load securement after initial movement and periodically during transit. Initial movement can settle loads and loosen restraints. Build inspection time into schedules.

6. Adverse Weather and Road Conditions

Beyond vehicle and cargo factors, environmental conditions significantly influence transportation safety. Weather and road surface conditions interact with driver behavior, vehicle capabilities, and operational decisions to create or mitigate safety hazards.

Rain reduces tire traction and creates visibility challenges. Water on roadways increases stopping distances. Hydroplaning occurs when tires cannot disperse water fast enough, causing complete loss of traction. Heavy rain overwhelms windscreen wipers, limiting driver visibility.

Fog severely restricts visibility while drivers often fail to reduce speed proportionally. Following vehicles too closely in fog creates rear-end collision risk. Drivers cannot see hazards in time to react.

Temperature-Related Hazards

Ice and snow create the most challenging road conditions. Black ice appears as wet pavement but offers virtually no traction. Snow accumulation reduces lane width and obscures road markings. Freezing temperatures affect brake system performance and tire flexibility.

Extreme heat affects pavement integrity and tire performance. Pavement can soften in high temperatures, particularly freshly sealed roads. Tire pressure increases with heat, potentially causing blowouts if tires were overinflated when cold.

Wind Conditions and High-Profile Vehicles

Strong winds affect high-profile vehicles like trucks, buses, and empty trailers. Crosswinds push vehicles laterally, requiring steering corrections. Sudden wind gusts can cause loss of control, particularly on bridges and in open areas.

Operators should monitor weather forecasts and warnings. Establish wind speed thresholds for suspending operations with high-profile vehicles. Some loads and vehicle configurations shouldn’t operate in high winds regardless of driver experience.

Operational Weather Response Procedures

Speed reduction represents the primary control measure for adverse weather. Reduce speed before conditions deteriorate. Don’t wait for loss of traction to recognize inadequate speed for conditions. Posted speed limits assume good weather and road conditions.

Increase following distances in reduced visibility and traction conditions. Standard following distance recommendations assume good conditions. Double or triple following distances when weather degrades stopping capability or reduces visibility.

Route planning should account for weather forecasts. Delay departures when severe weather is predicted. Identify alternate routes that avoid high-risk areas like mountain passes during snow or flood-prone areas during heavy rain.

Equip vehicles appropriately for expected conditions. Winter tires, tire chains, and traction devices should be available before winter arrives. Don’t wait for the first snowfall to discover inadequate preparation.

7. Slips, Trips, and Falls in Transport Operations

While previous sections addressed on-road safety hazards, slips, trips, and falls represent significant injuries in transport operations. These incidents occur during vehicle entry and exit, loading and unloading, and work in transport facilities.

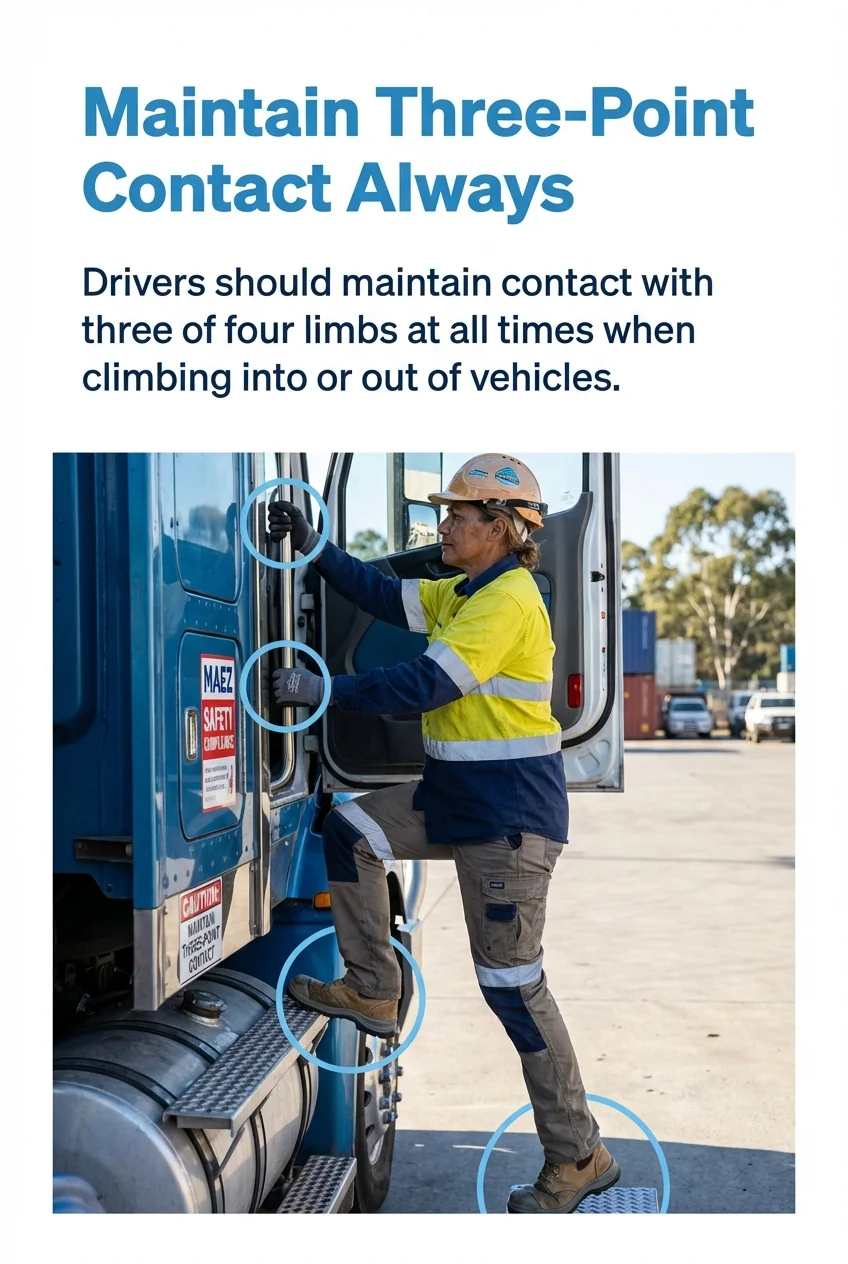

Vehicle entry and exit create fall hazards. Truck cabs sit high above ground. Steps become slippery when wet or contaminated with mud, oil, or ice. Drivers climbing into or down from cabs while carrying items lose the ability to maintain three-point contact.

Cargo trailer access requires climbing onto trailer decks or into container interiors. These surfaces lack handrails. They become extremely slippery in wet weather. Falls from trailer height cause serious injuries.

Loading Dock and Warehouse Hazards

Loading docks present multiple slip and trip hazards. Gaps between dock and trailer create catch points for feet. Dock plates that are inadequately secured can shift. Wet or oily dock surfaces reduce traction.

Warehouse floor conditions affect safety. Damaged flooring creates trip hazards. Spills and leaks create slip hazards. Inadequate lighting reduces ability to identify hazards. High-traffic areas develop wear patterns that create uneven surfaces.

Prevention Through Design and Procedures

Vehicle design should prioritize safe access. Steps should have aggressive tread patterns. Grab handles should be positioned for three-point contact. Consider vehicles with lower entry heights when operations require frequent entry and exit.

Implement and enforce three-point contact procedures. Drivers should maintain contact with three of four limbs at all times when climbing. This means not carrying items while climbing. Designate storage for items that need to move with drivers.

Maintain walking surfaces in good condition. Repair damaged flooring promptly. Clean spills immediately. Ensure adequate lighting in all work areas. These aren’t costly interventions. They’re basic maintenance that prevents injuries.

Weather Management for Exterior Surfaces

Exterior surfaces require weather-specific maintenance. Remove snow and ice from steps, walkways, and loading areas before work begins. Apply de-icing materials to prevent ice formation. Consider heated walking surfaces for high-traffic areas in cold climates.

Rain creates immediate slip hazards on smooth surfaces. Textured surfaces, drainage systems, and covered walkways reduce wet surface hazards. Provide adequate time for safe movement rather than forcing rushed activity in poor conditions.

The connection between these operational safety issues and broader regulatory compliance becomes clear when you examine Chain of Responsibility frameworks. The Heavy Vehicle National Law places obligations on all parties in the supply chain to prevent these hazards through systematic controls.

Building Sustainable Safety Systems

These seven transportation safety issues don’t operate in isolation. They interact and compound. Fatigued drivers are more easily distracted. Poor maintenance increases collision severity. Adverse weather magnifies the consequences of improper cargo securement.

Effective safety management addresses these hazards systematically rather than reactively. Implement scheduled maintenance programs before equipment fails. Design rosters that prevent fatigue before drivers become impaired. Establish loading procedures that ensure proper securement on every load.

Your safety system needs clear procedures, proper training, regular monitoring, and consistent enforcement. Document your processes. Train everyone affected by them. Verify through audits and inspections that actual practice matches documented procedures. Address deviations immediately before they become accepted practice.

Technology provides valuable tools for safety management. Telematics monitors driving behavior. Maintenance management systems track servicing. Electronic logbooks verify compliance with work hour limits. However, technology supplements rather than replaces systematic safety management and organizational culture.

Safety culture determines whether your documented systems translate to actual practice. Workers must believe that safety genuinely takes priority over production. This requires leadership commitment demonstrated through resource allocation, decision-making, and response to safety concerns. Stating that safety is important while punishing workers who report hazards creates cynicism, not compliance.

Start by conducting a thorough assessment of your current operations against these seven hazard categories. Identify gaps between regulatory requirements, your documented procedures, and actual practice. Prioritize addressing the gaps with highest risk potential first.

Implement changes systematically with proper communication and training. Monitor effectiveness through leading indicators like inspection completion rates and hazard reports, not just lagging indicators like crash statistics. Adjust your approach based on what your monitoring reveals.

Transport safety management is continuous work, not a project with an end date. Conditions change. New hazards emerge. Your safety systems must evolve accordingly. Regular review and update of your safety management approach ensures it remains relevant and effective as your operations develop.