The Heavy Vehicle National Law (HVNL) represents the most significant regulatory framework governing commercial transport operations in Australia, establishing uniform safety standards, compliance requirements, and enforcement protocols for vehicles exceeding 4.5 tonnes gross vehicle mass. Administered by the National Heavy Vehicle Regulator (NHVR), this legislation encompasses five distinct regulation sets covering vehicle standards, mass dimension and loading requirements, fatigue management protocols, access provisions, and registration obligations across six participating jurisdictions. The law operates through Queensland’s legislative framework but applies throughout New South Wales, Victoria, South Australia, Tasmania, and the Australian Capital Territory, creating operational consistency for interstate heavy vehicle movements while embedding Chain of Responsibility obligations that extend legal accountability across entire supply chains, from consignors and loaders to schedulers, operators, and drivers.

After spending 25 years working across supply chain operations in Australia and the UK, I’ve witnessed firsthand how regulatory frameworks shape operational practices. The HVNL stands apart because it shifts compliance thinking from purely driver-focused enforcement to supply chain-wide accountability.

This transformation affects how businesses structure contracts, manage vendor relationships, and design operational procedures. Understanding the HVNL isn’t just about avoiding penalties. It’s about building safer, more efficient transport operations that deliver competitive advantages through reduced insurance costs, improved service reliability, and stronger business relationships.

This guide will walk you through the law’s structure, scope, and practical application. You’ll understand who the NHVR regulates, how Chain of Responsibility obligations extend beyond traditional transport roles, and what the 2026 reforms mean for your operations.

What Is the Heavy Vehicle National Law?

The HVNL establishes the regulatory foundation for all commercial transport operations involving vehicles above 4.5 tonnes gross vehicle mass. This threshold captures everything from small rigid trucks to multi-trailer road trains.

The law operates as a national scheme hosted by Queensland, designed for consistent application across participating states and territories. This structure eliminates previous state-by-state variations that complicated interstate operations.

The legislation comprises several components working together. The Heavy Vehicle National Law Act 2012 provides the primary legislative framework. Five sets of regulations sit beneath this Act, addressing specific operational areas.

The Five HVNL Regulation Sets

Each regulation set targets distinct aspects of heavy vehicle operations. Understanding how these regulations interconnect helps you build compliance systems that address multiple requirements simultaneously.

| Regulation Set | Primary Focus | Key Requirements |

|---|---|---|

| Vehicle Standards | Equipment compliance | Australian Design Rules, modifications, defect management |

| Mass, Dimension and Loading | Physical limits | Weight limits, dimension restrictions, load restraint |

| Fatigue Management | Driver hours | Work diary requirements, rest breaks, scheduling controls |

| Access | Road network use | Permits, route approvals, special vehicle access |

| Registration | Vehicle identification | Registration processes, heavy vehicle levies, record keeping |

The Vehicle Standards regulations ensure heavy vehicles meet Australian Design Rules and maintain roadworthy conditions throughout their operational life. This covers everything from brake performance to lighting systems.

Mass, Dimension and Loading regulations set physical limits for vehicle operations. Ministers have endorsed recommendations to increase General Mass Limits to the levels currently applying under Concessional Mass Limits, streamlining access to higher productivity configurations.

Fatigue Management regulations control driver work and rest hours. These requirements extend beyond drivers to include anyone scheduling, directing, or influencing driver work patterns. This connection between operational planning and driver safety represents a fundamental HVNL principle.

Legislative Architecture

The HVNL employs a layered structure that separates high-level obligations from technical specifications. This design allows regulatory updates without constant legislative amendment.

Primary duties sit within the Act itself. These establish fundamental safety obligations that remain stable over time. Regulations beneath the Act contain detailed technical requirements that can adapt as vehicle technology and operational practices develop.

This structure supports the law’s risk-based approach. Rather than prescribing every operational detail, the HVNL establishes safety outcomes that parties must achieve. How you achieve those outcomes depends on your specific operational context.

History and Development of the HVNL

The HVNL emerged from decades of frustration with fragmented state-based regulations. Before 2014, interstate operators navigated different rules, permit systems, and enforcement approaches in each jurisdiction.

This inconsistency created operational inefficiencies and compliance complexity. A vehicle configured legally in New South Wales might violate Victorian regulations. Fatigue management rules varied between states, complicating driver scheduling for interstate trips.

The National Transport Commission led reform efforts, working with state and territory governments to develop consistent national regulations. This process involved extensive industry consultation and policy development spanning multiple years.

Implementation Timeline

The Heavy Vehicle National Law Act 2012 passed Queensland Parliament as the host jurisdiction legislation. Other participating states and territories then enacted application laws adopting Queensland’s legislation within their own legal frameworks.

Implementation occurred progressively across 2013 and early 2014. Queensland, New South Wales, and Victoria commenced operations under the HVNL first. South Australia, Tasmania, and the Australian Capital Territory joined the scheme later in 2014.

This staged approach allowed the NHVR to establish operational systems and iron out implementation challenges before extending coverage across all participating jurisdictions. Western Australia and the Northern Territory chose not to participate, maintaining separate heavy vehicle regulatory systems.

Establishing the National Heavy Vehicle Regulator

Creating the NHVR represented a fundamental shift in Australian transport regulation. Previously, each state operated its own heavy vehicle regulator with different policies and priorities.

The NHVR consolidated these functions into a single national body. This organization now handles registration, permits, accreditation, and compliance activities across participating jurisdictions. Enforcement officers operate under NHVR authority regardless of which state they’re working in.

This consolidation delivers consistency for operators. You deal with one regulator using consistent policies and procedures whether you’re operating in Tasmania or Queensland. Permit applications follow the same process regardless of which state roads you’re accessing.

When Did the HVNL Commence?

The HVNL officially commenced on 10 February 2014 in the initial participating jurisdictions. This date marked the transition from state-based regulations to the national scheme for Queensland, New South Wales, and Victoria.

South Australia, Tasmania, and the Australian Capital Territory commenced HVNL operations later in 2014. Each jurisdiction required its own application legislation and administrative preparations before joining the national scheme.

This implementation date matters for compliance purposes. Offences and enforcement activities after 10 February 2014 fall under HVNL provisions. Historical records and documentation from before this date may reference previous state-based requirements.

Transition Arrangements

The move to the HVNL included transition provisions allowing existing permits, accreditations, and registrations to continue under the new framework. This prevented operators from needing to immediately reapply for all authorities.

These provisions recognised that abrupt regulatory changes create operational disruption. Existing heavy vehicle registrations remained valid. Permits issued under previous state schemes continued until their expiry dates.

Accredited operators maintained their status during the transition. The NHVR assumed responsibility for these schemes, continuing existing arrangements while progressively implementing national standards.

Participating States and Territories

Six Australian jurisdictions participate in the HVNL scheme. These states and territories apply the law through their own application legislation, creating uniform regulations across their road networks.

Queensland hosts the legislation as the enacting jurisdiction. New South Wales, Victoria, South Australia, Tasmania, and the Australian Capital Territory apply this legislation within their own legal frameworks through application Acts.

This structure creates seamless operations for interstate transport. A vehicle complying with HVNL requirements in Queensland automatically meets requirements in Victoria. Fatigue management rules remain consistent regardless of which participating state you’re operating in.

Western Australia and Northern Territory

Western Australia and the Northern Territory maintain separate heavy vehicle regulatory systems outside the HVNL framework. These jurisdictions continue operating under state-based legislation with their own regulators.

This creates complexity for operators traveling to or from these jurisdictions. You must understand both HVNL requirements and WA or NT-specific regulations. A vehicle configured for HVNL compliance may need modifications to meet WA or NT standards.

Interstate operators face particular challenges. When you cross from South Australia into Western Australia, you transition between different regulatory systems. Permit requirements, fatigue management rules, and compliance obligations can differ significantly.

Cross-Border Operations

Managing operations across HVNL and non-HVNL jurisdictions requires careful attention to regulatory differences. This particularly affects businesses with national operations spanning all states and territories.

Develop systems that address the most stringent requirements across both frameworks. This approach ensures compliance regardless of which jurisdiction you’re operating in. It’s simpler than maintaining separate procedures for different jurisdictions.

Consider how scheduling and route planning account for regulatory transitions. When drivers cross from HVNL to non-HVNL jurisdictions, ensure they understand which requirements apply. This knowledge prevents inadvertent violations when regulatory frameworks change mid-journey.

Role of the National Heavy Vehicle Regulator

The NHVR functions as the primary regulatory authority for heavy vehicle operations across participating jurisdictions. This organization combines regulatory development, compliance support, and enforcement activities under one national body.

The regulator develops policies and guidelines interpreting HVNL requirements. These documents help operators understand how the law applies to specific situations. They provide practical guidance beyond what the legislation itself contains.

Registration services form a core NHVR function. The regulator processes heavy vehicle registrations, maintains registration records, and administers the heavy vehicle charging scheme funding road infrastructure maintenance.

Compliance and Enforcement Functions

NHVR enforcement officers conduct roadside inspections, investigate serious incidents, and take prosecution action for significant breaches. These officers operate across all participating jurisdictions under consistent enforcement protocols.

The regulator employs risk-based enforcement strategies. Resources target high-risk operators and behaviors that pose the greatest safety threats. This approach focuses enforcement where it delivers maximum safety benefit.

Compliance support activities complement enforcement functions. The NHVR provides education resources, conducts industry engagement, and offers guidance helping operators achieve compliance. This balanced approach recognizes that most operators want to comply but need support understanding complex requirements.

Permit and Accreditation Administration

The NHVR processes access permits for vehicles or loads exceeding standard limits. This includes oversize and overmass permits, special purpose vehicle authorities, and notices for particular vehicle configurations.

The HVNL reform includes requirements for businesses in the National Heavy Vehicle Accreditation Scheme (NHVAS) to have documented safety management systems. The NHVR administers this scheme, assessing operator systems and conducting audits verifying ongoing compliance.

Accreditation delivers operational benefits including access to higher mass limits, streamlined permit processes, and reduced compliance burden. The scheme recognizes operators demonstrating mature safety management systems through documented processes and performance monitoring.

Understanding Chain of Responsibility

Chain of Responsibility (CoR) represents the HVNL’s most distinctive feature. This framework extends legal obligations beyond vehicle operators and drivers to every party influencing heavy vehicle safety.

CoR recognizes that operational decisions made far from the roadside directly impact safety outcomes. When a scheduler creates unrealistic delivery timeframes, drivers face pressure to speed or skip rest breaks. When a loader exceeds mass limits, the driver operates an unsafe vehicle.

The law addresses this reality by imposing duties on every supply chain participant. If your business decisions or actions can affect heavy vehicle safety, you hold CoR obligations regardless of whether you own trucks or employ drivers.

Who Holds CoR Obligations?

The HVNL identifies specific parties within the supply chain holding CoR duties. These parties include employers, prime contractors, operators, schedulers, consignors, consignees, packers, loading managers, loaders, and drivers.

Each role attracts duties related to its sphere of influence. Consignors must not demand unreasonable delivery timeframes creating fatigue risks. Loaders must ensure vehicles aren’t overloaded. Schedulers must create realistic schedules allowing drivers to comply with rest requirements.

This structure means multiple parties can share responsibility for the same breach. If a driver exceeds speed limits meeting an unrealistic schedule, both the driver and scheduler may face liability. This shared accountability encourages cooperation in managing safety risks.

Primary Duty Requirements

Every CoR party holds a primary duty to ensure their conduct doesn’t cause or contribute to breaches. This positive obligation requires taking active steps to eliminate or minimize safety risks.

The primary duty operates as a risk management obligation. You must identify reasonably foreseeable risks arising from your business activities, then implement controls eliminating or minimizing those risks so far as is reasonably practicable.

This approach mirrors workplace health and safety legislation. Rather than prescribing specific controls, the law requires achieving safety outcomes appropriate to your operational context. How you discharge this duty depends on the specific risks your business activities create.

Positive Duty and Reasonable Steps

Demonstrating compliance with primary duty obligations requires evidence of reasonable steps taken to prevent breaches. This focuses regulatory attention on your systems and processes, not just outcomes.

Reasonable steps might include implementing documented procedures, providing training, conducting audits, monitoring compliance, and taking corrective action when risks emerge. What constitutes reasonable steps varies based on your business size, resources, and the nature of risks you influence.

Documentation becomes critical under this framework. If an incident occurs, you need evidence showing the reasonable steps you took to prevent it. This shifts the burden of proof in your favor when you can demonstrate proactive risk management.

Fatigue Management Requirements

Fatigue management regulations control driver work and rest hours to prevent fatigue-related incidents. These requirements recognize that tired drivers pose serious safety risks to themselves and other road users.

The regulations establish maximum work hours, minimum rest breaks, and record-keeping obligations. Three distinct options exist for managing fatigue: Standard Hours, Basic Fatigue Management, and Advanced Fatigue Management.

Standard Hours provide simple, prescriptive limits suitable for straightforward operations. Basic Fatigue Management offers some flexibility with additional management systems. Advanced Fatigue Management allows maximum flexibility for operators demonstrating sophisticated fatigue risk management.

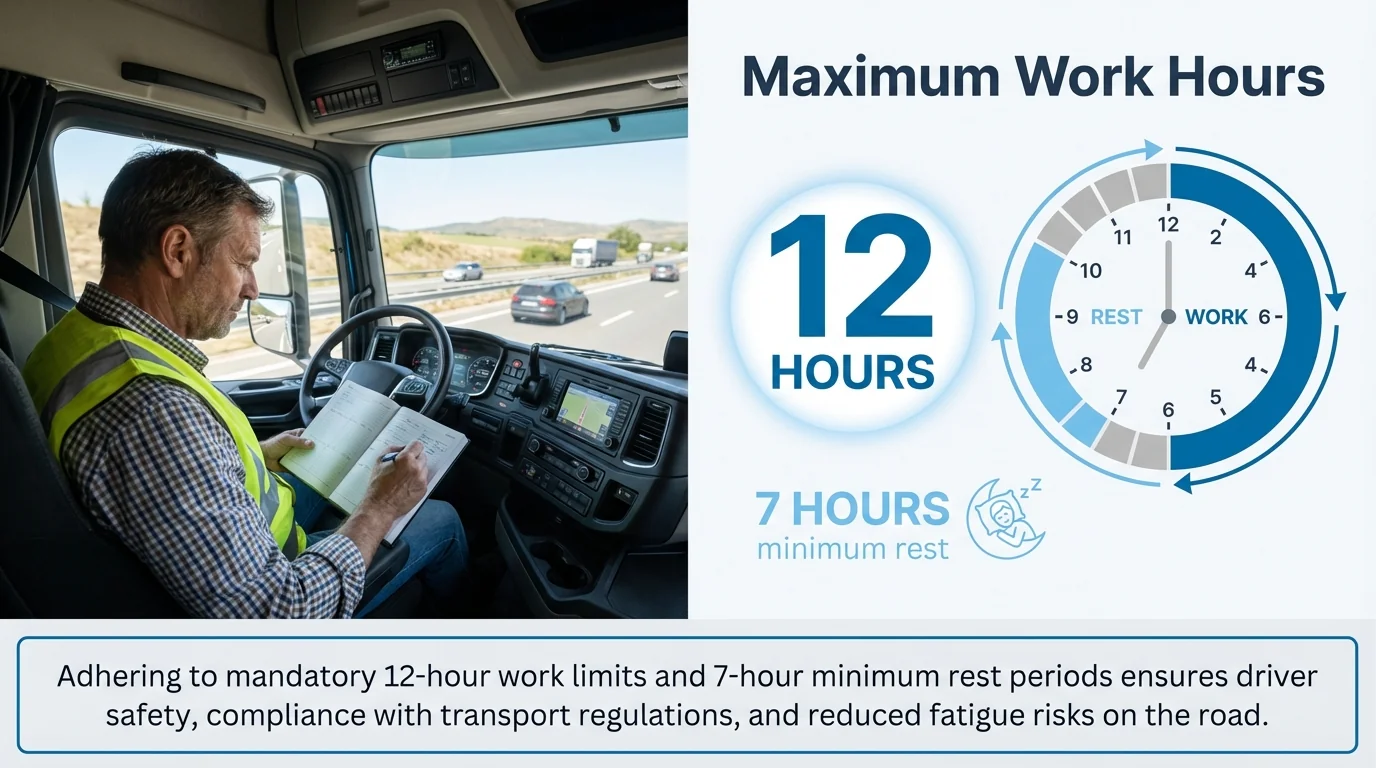

Standard Hours Requirements

Standard Hours establish work and rest limits that drivers can follow without additional management systems. These rules set maximum driving hours, minimum rest breaks, and maximum work limits across different timeframes.

Drivers can work up to 12 hours in any 24-hour period under Standard Hours. They must take at least 7 hours of rest in every 24-hour period. Night rest requirements mandate specific minimum rest periods during nighttime hours.

Rolling work hour limits prevent cumulative fatigue. Drivers can’t exceed 72 hours work in any 7-day period or 144 hours in any 14-day period. These limits ensure adequate recovery time accumulates despite day-to-day variation in work patterns.

Work Diary Obligations

Drivers operating under Standard Hours or Basic Fatigue Management must maintain work diaries recording their work and rest times. These records provide evidence of compliance with fatigue management requirements.

Work diaries must record driving time, work time, rest breaks, and other activities. Entries must be made in real-time or as soon as practicable. The diary provides an auditable record that enforcement officers can check during roadside inspections.

Electronic work diaries have largely replaced paper-based systems. These electronic logging devices automatically record driving time and integrate with vehicle monitoring systems. They reduce administrative burden while improving record accuracy.

Scheduler and Consignor Obligations

Fatigue management obligations extend beyond drivers to parties influencing work patterns. Schedulers must create schedules allowing drivers to comply with work and rest requirements. Consignors must avoid demanding unreasonable delivery timeframes creating fatigue risks.

This extension of responsibility addresses root causes of fatigue violations. Drivers often exceed hours because business demands make compliance impossible. By imposing duties on schedulers and consignors, the law targets the commercial pressures creating fatigue risks.

Practical compliance requires understanding your transport provider’s operations. When negotiating delivery timeframes, ensure schedules allow adequate driving time and rest breaks. Consider distances, road conditions, and rest requirements when setting delivery expectations.

Mass, Dimension and Loading Regulations

Mass, dimension and loading regulations establish physical limits for heavy vehicle operations. These requirements protect road infrastructure, prevent vehicle instability, and ensure adequate braking performance.

Mass limits specify maximum weights for individual axles, axle groups, and total vehicle combinations. These limits vary based on axle spacing, suspension types, and road category. Higher productivity routes allow increased mass limits for specific configurations.

Dimension limits control vehicle length, width, and height. Standard dimension vehicles can operate without special permits on most roads. Vehicles exceeding standard dimensions require access permits specifying approved routes and operating conditions.

General Mass Limits and Concessional Mass Limits

General Mass Limits (GML) establish baseline weight restrictions applying to all heavy vehicles. These limits balance road protection with operational efficiency.

Concessional Mass Limits (CML) previously allowed higher weights for vehicles meeting specific technical requirements. The distinction between GML and CML created complexity, with operators needing to understand which limits applied to their configuration.

Reform addresses this complexity. Regulatory amendments consolidate these limits, eliminating the separate CML category while maintaining access to higher weights for qualifying vehicles. This simplification reduces confusion while preserving operational flexibility.

Load Restraint Requirements

Load restraint regulations ensure cargo remains secure during transport. Inadequate restraint causes load shift, creating vehicle instability and spillage risks. Proper restraint protects the driver, vehicle, cargo, and other road users.

The Load Restraint Guide provides detailed technical guidance on restraint methods. This document covers tie-down patterns, chain ratings, tensioning requirements, and containment systems. Following these guidelines demonstrates compliance with regulatory obligations.

CoR parties beyond drivers hold load restraint obligations. Packers must secure cargo properly. Loading managers must ensure appropriate restraint systems are used. Consignors must communicate special handling requirements for their goods. This shared responsibility ensures restraint receives attention throughout the supply chain.

Intelligent Access Program

The Intelligent Access Program (IAP) uses GPS monitoring to verify vehicle compliance with access conditions. Operators with IAP accreditation can access higher mass limits and restricted routes by demonstrating real-time compliance monitoring.

IAP systems track vehicle location, speed, and route adherence. This data provides assurance to road managers that vehicles comply with permit conditions. In return, operators gain access to operational efficiencies unavailable to non-monitored vehicles.

This technology-enabled approach represents the HVNL’s future direction. Rather than relying solely on roadside enforcement, the regulator increasingly uses monitoring systems providing continuous compliance assurance. This delivers benefits for both regulators and compliant operators.

Vehicle Standards and Registration

Vehicle standards regulations ensure heavy vehicles meet Australian Design Rules and maintain roadworthy conditions throughout their operational life. These requirements cover everything from lighting systems to brake performance.

Registration requirements establish processes for bringing vehicles into the system, maintaining registration currency, and paying the heavy vehicle charges funding road maintenance. The NHVR maintains the national heavy vehicle register tracking all registered heavy vehicles.

Modification approval processes ensure changes to registered vehicles maintain compliance with design rules. Significant modifications require approval before implementation. This prevents changes that compromise vehicle safety or roadworthiness.

Roadworthiness Obligations

Heavy vehicles must remain roadworthy throughout their registration period. This obligation extends beyond operators to include drivers, who must not operate defective vehicles, and repairers, who must ensure repairs meet required standards.

Regular maintenance schedules help maintain roadworthiness. Vehicle systems deteriorate through normal use. Systematic maintenance identifies and addresses wear before components reach failure point.

Pre-trip inspections provide the final check before each journey. Drivers must conduct daily inspections covering critical safety systems. These inspections catch defects that have developed since the last maintenance check.

Heavy Vehicle National Law and Maintenance Management

Effective maintenance management requires documented systems specifying inspection frequencies, maintenance standards, and record-keeping practices. These systems demonstrate your approach to maintaining roadworthy vehicles.

Maintenance schedules should reflect manufacturer recommendations, operational conditions, and regulatory requirements. Severe operating conditions may warrant more frequent servicing than manufacturer intervals suggest.

Record-keeping proves maintenance compliance. Keep detailed records of inspections, repairs, and parts replacements. These records demonstrate your maintenance program’s effectiveness and help identify recurring issues requiring attention.

HVNL Reform and 2025 Amendments

The amended HVNL is expected to commence in mid-2026, introducing significant reforms to Chain of Responsibility, mass management, and safety duty provisions. These changes represent the most substantial regulatory update since the law’s initial implementation.

Reform objectives include improving regulatory clarity, reducing compliance burden, and modernizing safety management approaches. The amendments shift focus from prescriptive rules toward risk-based safety outcomes.

These changes affect how businesses demonstrate compliance. Rather than simply following detailed procedures, operators must show they understand risks and implement appropriate controls. This approach rewards sophisticated safety management while maintaining protections for basic operators.

Enhanced Safety Duties

Reformed primary duty provisions clarify what reasonable steps mean in practice. The amendments specify factors determining what’s reasonably practicable, helping businesses understand their obligations.

These factors include knowledge about hazards and risks, availability and suitability of control measures, and costs of controls relative to the degree of risk. This framework guides decision-making about safety investments and risk controls.

Due diligence obligations for executives receive greater emphasis. Officers and directors must actively ensure their organizations meet safety obligations. This includes understanding HVNL requirements, verifying appropriate resources are allocated, and ensuring effective safety systems exist.

Mass Management Changes

Mass management reforms streamline access to higher productivity configurations. Consolidating GML and CML simplifies the regulatory framework while maintaining infrastructure protection.

New technology provisions support weight monitoring systems. These systems can demonstrate mass compliance without traditional weighbridge checks. This technology-enabled approach reduces delays while providing reliable compliance data.

The reforms recognize that modern vehicles and monitoring technology enable safe operations at higher weights than historical limits allowed. The regulatory changes align with these technological capabilities.

Preparing for 2026 Implementation

Start preparing now for the 2026 reforms. Review your existing safety management systems against the new requirements. Identify gaps between current practices and reformed obligations.

Focus on Chain of Responsibility documentation. The reformed law emphasizes demonstrating reasonable steps through documented systems. Ensure your procedures address foreseeable risks and specify controls.

Consider how technology can support compliance. Electronic monitoring systems, telematics, and digital documentation tools all help demonstrate compliance under the risk-based approach. Invest in systems that provide reliable compliance data.

Compliance and Enforcement Under HVNL

NHVR enforcement officers conduct roadside inspections, investigate incidents, and take prosecution action for serious breaches. Enforcement activities target high-risk behaviors and operators demonstrating consistent non-compliance.

The regulator employs graduated enforcement responses. Minor breaches may receive education and warnings. Serious or repeated violations attract formal enforcement action including infringement notices, improvement notices, or prosecutions.

Roadside inspections check compliance across multiple regulatory areas simultaneously. Officers examine vehicle roadworthiness, driver fatigue records, mass limits, load restraint, and registration currency. A single inspection can identify breaches spanning several regulation sets.

Penalty Framework

The HVNL establishes penalty levels based on breach severity. Minor breaches attract lower penalties. Serious breaches involving substantial risk or commercial advantage receive significantly higher penalties.

Penalties can apply to individuals or corporations. Court-imposed penalties for serious breaches can reach hundreds of thousands of dollars for companies. Individual offenders face substantial fines and potential imprisonment for the most serious violations.

CoR breaches can result in multiple parties facing penalties for the same incident. When an overloaded vehicle is detected, the driver, operator, loader, and consignor may all face charges if their conduct contributed to the breach.

Improvement and Prohibition Notices

NHVR inspectors can issue improvement notices requiring parties to rectify identified breaches within specified timeframes. These notices provide opportunities to achieve compliance without formal prosecution.

Prohibition notices immediately prevent specific activities posing serious safety risks. An inspector finding a vehicle with critical mechanical defects can prohibit its operation until repairs are completed. These notices protect immediate safety while allowing compliance restoration.

Responding promptly to notices demonstrates commitment to compliance. Treat notices seriously and implement required changes within specified timeframes. Document your corrective actions thoroughly.

Building Effective Compliance Systems

Effective compliance requires systematic approaches addressing all HVNL obligations relevant to your operations. Scattered reactive responses don’t provide the protection documented management systems deliver.

Start by identifying which HVNL provisions affect your business. Map your activities against CoR obligations, fatigue management requirements, mass limits, and other applicable regulations. This assessment reveals your compliance landscape.

Develop documented procedures addressing identified obligations. These procedures should specify what actions you take to manage relevant risks, who holds responsibility for each action, and how you verify effectiveness.

Risk Assessment Processes

Conduct regular risk assessments examining how your business activities might contribute to HVNL breaches. Consider commercial pressures, operational constraints, and communication gaps that could create compliance risks.

Risk assessments should involve frontline workers who understand operational realities. Drivers, warehouse staff, and planners often identify risks that office-based managers miss. Their insights improve risk assessment accuracy.

Document identified risks and your control measures. This documentation demonstrates the reasonable steps you’re taking to prevent breaches. Update risk assessments when operations change or incidents reveal previously unidentified risks.

Training and Competency Development

Ensure everyone in your supply chain understands their HVNL obligations. This includes your own staff and external parties like transport providers, warehouse operators, and customers whose actions affect heavy vehicle safety.

Training should cover specific obligations applying to each role. Schedulers need detailed understanding of fatigue management requirements. Warehouse staff need thorough load restraint knowledge. Executives need awareness of their due diligence duties.

Document training delivery and assess competency. Keep records showing who received training, when it occurred, and what content was covered. These records prove you’ve taken reasonable steps to ensure understanding across your organization.

Monitoring and Continuous Improvement

Implement monitoring systems tracking compliance performance. Regular audits, inspection programs, and incident investigations identify system weaknesses requiring attention.

Monitoring data should inform continuous improvement activities. When audits reveal consistent gaps in particular areas, adjust your systems to address root causes. This proactive approach prevents breaches rather than simply reacting to problems.

Review your compliance systems annually. HVNL requirements change through regulatory amendments and enforcement precedents. Your systems must adapt to these changes to remain effective.

Common Challenges and Practical Solutions

Many businesses struggle translating HVNL obligations into practical operational procedures. The law’s broad risk-based language doesn’t always clearly indicate specific actions required. This ambiguity creates uncertainty about compliance.

Address this challenge by focusing on foreseeable risks in your specific operations. Don’t try to address every theoretical possibility. Identify the risks most likely to arise in your context, then implement practical controls.

Supply chain visibility presents another common challenge. When you engage transport providers, you lose direct control over driver management, vehicle maintenance, and operational decisions. Yet you maintain CoR obligations requiring oversight of these activities.

Managing Third-Party Providers

Develop qualification processes for transport providers. Assess their safety management systems, HVNL compliance capabilities, and performance history before engagement. This due diligence demonstrates reasonable steps to ensure supplier capability.

Contractual terms should clearly specify HVNL compliance obligations. Include provisions requiring providers to maintain work diaries, comply with mass limits, ensure vehicle roadworthiness, and report incidents. Make compliance an explicit contractual requirement.

Monitor provider performance through periodic audits, incident reviews, and compliance reporting. Don’t simply assume providers are complying. Regular verification protects your organization from liability arising from provider breaches.

Balancing Commercial and Compliance Pressures

Commercial pressures often conflict with compliance requirements. Customers demand shorter delivery times. Cost pressures encourage maximum utilization. These pressures create risks when they push operations beyond regulatory limits.

Recognize that compliance delivers commercial benefits alongside regulatory protection. Safe operations reduce insurance costs, prevent disruption from incidents, and protect your reputation. Frame compliance as business enablement, not just regulatory burden.

When commercial and compliance requirements conflict, compliance must prevail. Taking calculated compliance risks rarely delivers the commercial benefits anticipated while exposing your business to substantial penalties and reputational damage.

Next Steps for Your Business

Understanding the HVNL provides the foundation for compliance. The next step involves translating this knowledge into operational practice within your specific business context.

Start with a compliance gap assessment. Review your current practices against the obligations outlined in this guide. Identify areas where your systems don’t adequately address HVNL requirements. This assessment reveals priorities for compliance development.

Consider engaging specialist expertise for complex compliance requirements. The HVNL’s breadth and technical complexity mean few businesses possess internal expertise covering all obligations. Specialist support accelerates compliance development while ensuring regulatory accuracy.

Prepare now for the 2026 reforms. Don’t wait until implementation to start adapting your systems. Early preparation provides time to embed changes properly rather than rushing last-minute adjustments.

Focus particularly on Chain of Responsibility documentation. The reformed primary duty provisions emphasize demonstrating reasonable steps through documented processes. Investing in documentation now positions your business well for the new regulatory environment.

Remember that compliance isn’t a destination but an ongoing journey. Regulatory requirements change, operations develop, and risks evolve. Effective compliance requires continuous attention, regular review, and willingness to adapt systems as circumstances change.

The HVNL framework provides structure for managing heavy vehicle safety risks systematically. Rather than viewing it as regulatory burden, recognize it as a framework supporting safer, more efficient operations that deliver competitive advantages for well-managed businesses. Understanding penalties and enforcement helps contextualize the importance of proactive compliance management.