Implementing a Safety Management System transforms compliance from a regulatory burden into an operational advantage. Organisations consistently report substantial reductions in workplace incidents, but success depends entirely on how well you structure your approach from day one.

A safety management system is a structured framework for managing workplace health and safety risks. It integrates policies, procedures, and practices to identify hazards, assess risks, implement controls, and continuously improve safety performance across your organisation.

This matters because reactive safety approaches no longer meet modern workplace demands. Today’s operations require systematic hazard identification, proactive risk management, and genuine employee participation in safety processes.

The implementation journey involves four critical stages: gaining leadership commitment, establishing safety policies, conducting thorough risk assessments, and building continuous improvement mechanisms. Each stage builds on the previous one, creating a sustainable safety culture.

By the end of this guide, you’ll understand exactly how to structure your SMS implementation, engage your workforce effectively, and create safety systems that deliver measurable results while supporting operational efficiency.

Understanding Safety Management Systems and Their Purpose

A safety management system provides a structured approach to managing workplace safety. It moves organisations beyond reactive responses to incidents toward proactive identification and control of workplace hazards.

The system operates through interconnected components. Management leadership sets the direction. Employee participation identifies ground-level risks. Hazard identification and risk assessment processes pinpoint dangers before they cause harm.

These elements work together systematically. When leadership commits resources and attention to safety, employees engage more actively in hazard reporting. Better hazard identification leads to more effective controls. Effective controls reduce incidents and build confidence in the system.

The purpose extends beyond regulatory compliance. A well-designed SMS improves operational efficiency by reducing disruptions from incidents. It lowers insurance costs through demonstrated risk management. It strengthens workplace culture when employees see their safety concerns addressed systematically.

Companies integrating SMS with business operations report improved regulatory compliance and operational efficiency. The system becomes part of how work gets done, not an additional burden on operations.

Modern safety management systems align with standards like OSHA guidelines and ISO 45001. These frameworks provide proven structures that courts and regulators recognise. They also enable organisations to benchmark their performance against industry standards.

Core Elements That Make Safety Management Systems Effective

Now that you understand what an SMS accomplishes, let’s examine the five elements that make it work. Each element plays a specific role in creating workplace safety.

Management Leadership and Organisational Commitment

Senior management approval and active participation drive SMS success. Leadership commitment means more than signing a policy document. It requires allocating resources, participating in safety activities, and holding people accountable for safety performance.

Management demonstrates commitment through visible actions. This includes attending safety meetings, conducting workplace inspections, and responding promptly to safety concerns. When executives prioritise safety in decision-making, the entire organisation follows suit.

Resource allocation reveals true commitment levels. Effective SMS implementation requires budget for training, equipment, controls, and ongoing evaluation. Management must also dedicate staff time for safety activities without treating it as secondary to production.

Active Employee Participation and Engagement

Workers closest to hazards often spot risks that management overlooks. Employee participation transforms safety from a top-down mandate into a shared responsibility across the organisation.

Participation takes concrete forms. Establish safety committees with worker representation. Create reporting channels where employees can raise concerns without fear. Involve workers in hazard assessments and control selection for their work areas.

Regular safety audits and employee training are associated with increased hazard reporting and earlier risk mitigation. When employees feel heard and see their input acted upon, they engage more actively in safety processes.

Worksite Analysis and Hazard Identification

Systematic hazard identification forms the foundation of effective safety management. You cannot control risks you haven’t identified. Comprehensive worksite analysis looks at physical hazards, chemical exposures, ergonomic risks, and process safety concerns.

Multiple identification methods strengthen your approach. Conduct regular workplace inspections using standardised checklists. Review incident and near-miss reports for patterns. Analyse job tasks to identify hazards at each step. Consult workers performing the tasks daily.

Risk assessment follows identification. Evaluate each hazard’s potential severity and likelihood. Consequence and probability matrices help prioritise which risks require immediate attention versus longer-term controls.

Hazard Prevention and Control Implementation

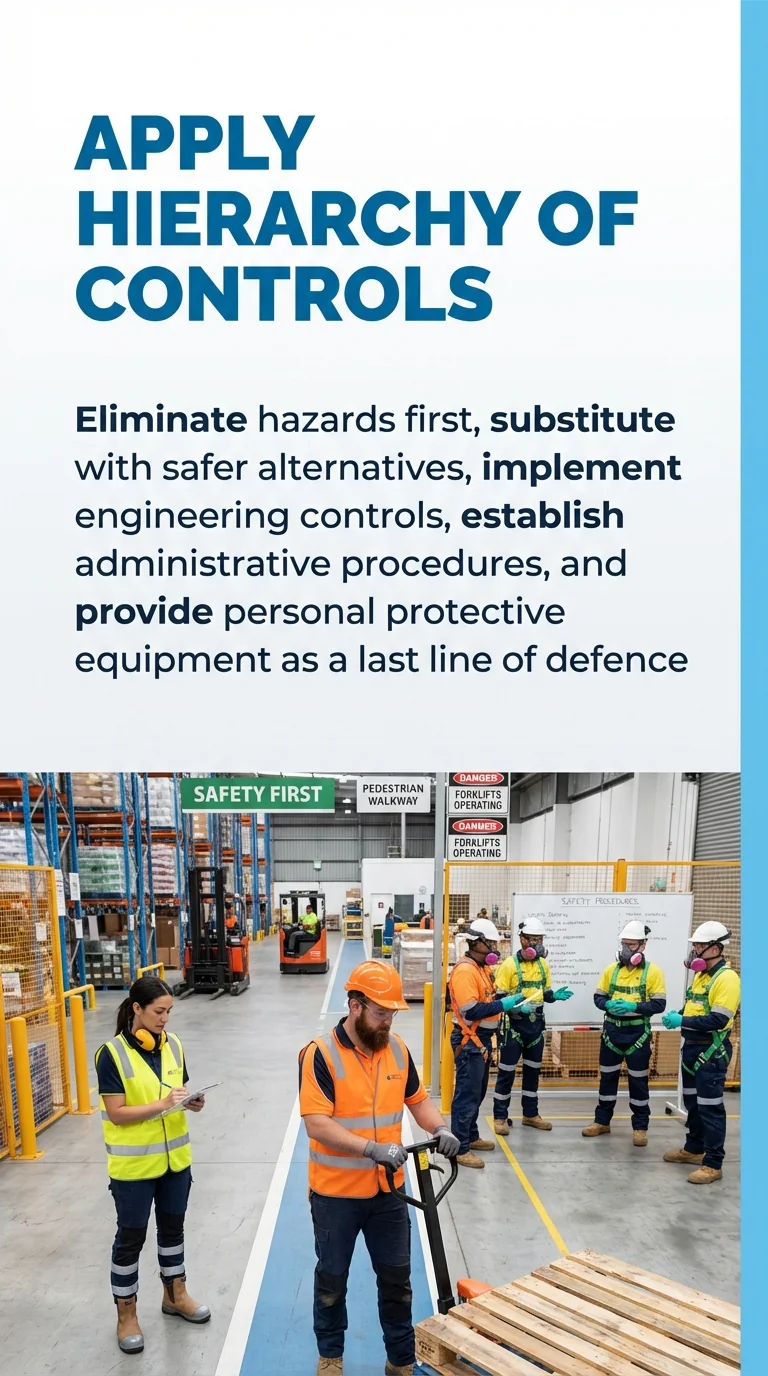

Identifying hazards means nothing without effective controls. The hierarchy of controls guides selection: eliminate hazards first, substitute with safer alternatives, implement engineering controls, establish administrative procedures, and provide personal protective equipment as a last line of defence.

Engineering controls deliver the most reliable protection. Physical barriers, machine guards, ventilation systems, and automated processes remove human error from the safety equation. Administrative controls and training add additional layers but depend on consistent human behaviour.

Document your control measures clearly. Workers need to understand what controls exist, why they matter, and how to use them correctly. Regular maintenance ensures controls continue functioning as designed.

Training Programs and Safety Education

Training builds workforce competence in safety practices. New employees need orientation covering workplace hazards, emergency procedures, and their safety responsibilities. Task-specific training ensures workers understand risks and controls for their particular jobs.

Training extends beyond initial orientation. Refresher programs reinforce key concepts. Updates address new hazards or changed procedures. Supervisors need additional training on their safety leadership responsibilities.

Effective training is interactive and practical. Demonstrations, hands-on practice, and scenario discussions engage participants better than lecture-only formats. Verify understanding through practical assessments, not just written tests.

Step 1: Secure Management Commitment and Define Scope

With core elements understood, implementation begins with leadership alignment. This first step establishes the foundation everything else builds upon.

Building the Business Case for SMS Investment

Senior management responds to clear business arguments. Calculate current incident costs including direct expenses, lost productivity, increased insurance premiums, and regulatory penalties. Project potential savings from reduced incidents.

Present SMS as an operational improvement tool, not just compliance overhead. Highlight efficiency gains from standardised processes. Show how proactive hazard identification prevents costly disruptions. Connect safety performance to business outcomes that executives care about.

Benchmark against industry standards and competitors. Demonstrate how structured safety systems position the organisation favourably with customers, insurers, and regulators.

Defining Implementation Scope and Boundaries

Clarify exactly what your SMS will cover. Which facilities fall under the system? Which operations and activities? What about contractors and visitors? Clear scope prevents gaps and confusion during implementation.

Consider starting with a pilot program in one facility or operation. This allows you to refine processes before organisation-wide rollout. Document lessons learned and success metrics to support broader implementation.

Establish realistic timelines. SMS implementation typically spans 12 to 24 months for complete deployment. Break this into phases with specific milestones. Quick wins in early phases build momentum for longer-term changes.

Assigning Roles and Accountability

Designate a senior leader as SMS executive sponsor. This person champions the program at the highest levels and removes implementation barriers. They also hold department managers accountable for safety performance in their areas.

Appoint an SMS coordinator to manage day-to-day implementation. This role coordinates training, tracks progress, maintains documentation, and facilitates communication across departments. The coordinator needs sufficient authority and resources to drive change.

Define safety responsibilities at every organisational level. Executives set direction and allocate resources. Managers implement programs in their areas. Supervisors enforce safe work practices daily. Workers follow procedures and report hazards. Clear accountability prevents safety from becoming everyone’s job but no one’s responsibility.

Step 2: Develop Your Safety Policy and Objectives

With commitment secured, the next step creates your safety direction. Your policy statement and objectives guide all subsequent SMS activities.

Crafting a Meaningful Safety Policy Statement

Your safety policy declares organisational values and commitments. It should be concise, memorable, and genuine. Avoid generic statements that could apply to any organisation. Instead, reflect your specific context and priorities.

Include commitments to hazard elimination, regulatory compliance, continuous improvement, and employee participation. State that safety ranks equally with other business priorities like quality and productivity. Acknowledge management responsibility for providing safe working conditions.

The policy requires visible executive signature. Display it prominently in workplaces. Include it in employee handbooks and orientation materials. Reference it in safety communications to reinforce its importance.

Setting Measurable Safety Objectives

Objectives translate policy into specific targets. They should align with broader business goals while addressing identified safety gaps. Use SMART criteria: specific, measurable, achievable, relevant, and time-bound.

Mix leading and lagging indicators. Lagging indicators like injury rates show results but don’t predict future performance. Leading indicators like inspection completion rates, training participation, and hazard reports filed predict safety performance before incidents occur.

| Objective Type | Example Objective | Measurement Method |

|---|---|---|

| Lagging Indicator | Reduce recordable injuries by 25% within 12 months | Monthly OSHA 300 log review |

| Leading Indicator | Complete 100% of scheduled safety inspections monthly | Inspection tracking system reports |

| Participation | Achieve 80% employee completion of safety training modules | Learning management system data |

| Engagement | Increase hazard reports submitted by 50% year-over-year | Incident reporting system analytics |

Review objectives quarterly. Adjust targets based on performance trends and changing business conditions. Celebrate achievements to maintain momentum and reinforce safety priorities.

Step 3: Conduct Thorough Hazard Identification and Risk Assessment

Your policy and objectives now established, systematic hazard identification begins. This step reveals the specific risks your controls must address.

Implementing Multiple Identification Methods

Comprehensive hazard identification uses several complementary approaches. Workplace inspections provide regular systematic reviews. Review incident reports and near-miss data for recurring patterns. Conduct job hazard analyses breaking tasks into steps.

Engage employees directly in identification. They experience workplace risks daily and often spot hazards others miss. Use safety committees, suggestion programs, and regular safety talks to gather their insights.

Consider all hazard categories. Physical hazards include slip/trip/fall risks, moving machinery, and electrical exposures. Chemical hazards encompass toxic substances, flammable materials, and harmful dusts. Ergonomic hazards relate to repetitive motions, awkward postures, and heavy lifting. Process hazards involve equipment failures, procedural errors, and emergency scenarios.

Assessing and Prioritising Identified Risks

Not all hazards pose equal risk. Risk assessment evaluates both potential consequence severity and likelihood of occurrence. This prioritisation guides resource allocation toward highest risks first.

Use a risk matrix to evaluate each hazard systematically. Rate potential severity from minor injury to fatality. Assess likelihood from rare to frequent based on exposure and existing controls. Plot each hazard on the matrix to determine priority level.

High-risk hazards demand immediate action. Medium risks require planned controls within defined timelines. Lower risks may accept current controls while remaining under periodic review.

Document your risk assessments thoroughly. Record identified hazards, assessment methodology, risk ratings, and planned control measures. This documentation demonstrates due diligence and guides implementation priorities.

Step 4: Design and Implement Hazard Controls

Risk assessment complete, you can now select appropriate controls. This step applies the hierarchy of controls to address identified hazards effectively.

Applying the Hierarchy of Controls

The most effective controls eliminate hazards entirely. Can you remove the hazardous task, substance, or condition? Elimination provides permanent protection without relying on ongoing compliance.

When elimination isn’t feasible, substitute with safer alternatives. Replace toxic chemicals with less hazardous materials. Use mechanical assists instead of manual lifting. Substitution reduces risk while allowing work to continue.

Engineering controls come next. Install machine guards, improve ventilation, add safety interlocks, and implement automated processes. These controls work automatically without requiring worker action or decision-making.

Administrative controls establish safe work procedures. Develop job procedures, implement permit systems, rotate workers to limit exposure, and schedule high-risk work during optimal conditions. These depend on consistent human compliance.

Personal protective equipment provides the last defence layer. While essential for many tasks, PPE requires proper selection, fit, maintenance, and consistent use. Never rely on PPE when higher-level controls could reduce the hazard itself.

Developing Standard Operating Procedures

Document safe work procedures for high-risk tasks. Effective procedures are concise, specific, and written for the workers performing the task. Use simple language, clear steps, and visual aids where helpful.

Include critical safety requirements in each procedure. What hazards exist? What controls must be in place? What protective equipment is required? What are emergency response steps if something goes wrong?

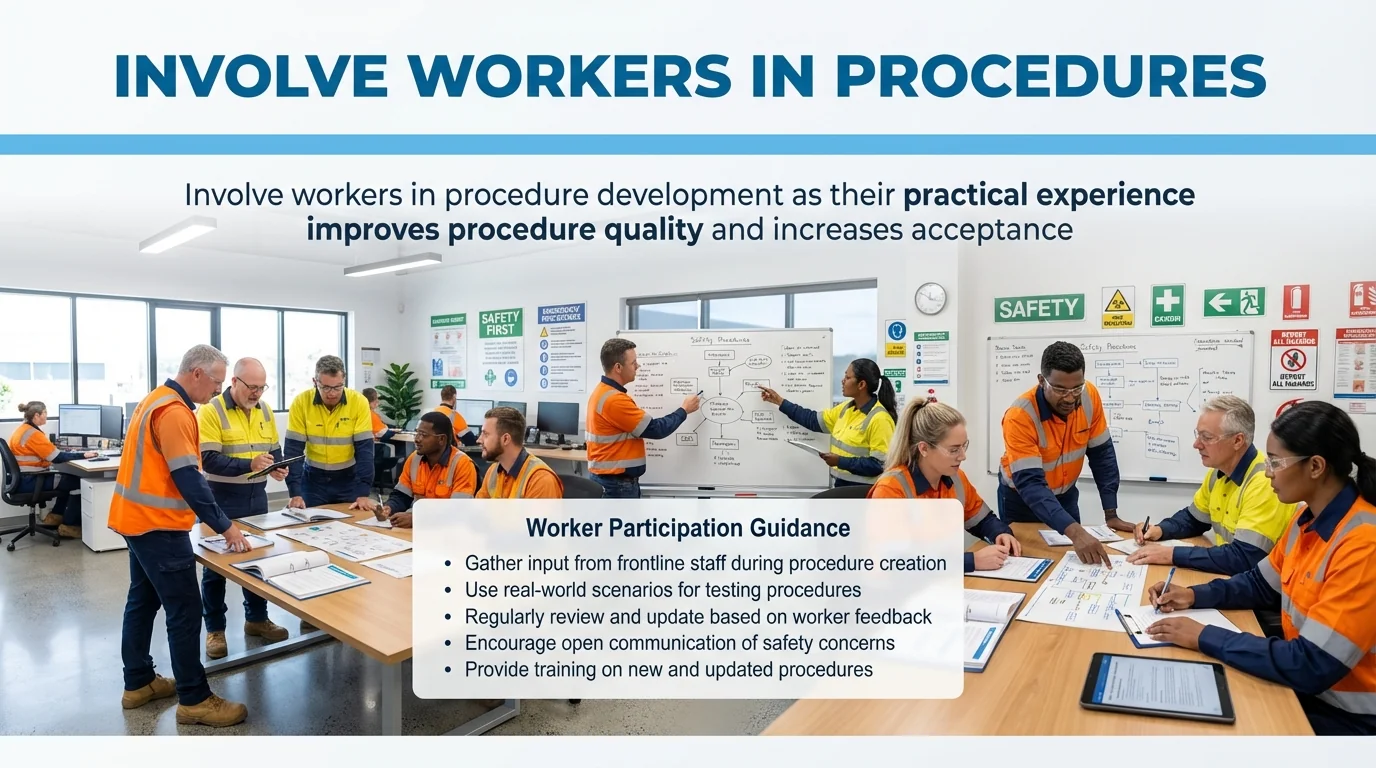

Involve workers in procedure development. Their practical experience improves procedure quality and increases acceptance. Test draft procedures in the field and refine based on feedback before finalising.

Establishing Emergency Preparedness Plans

Prepare for potential emergency scenarios. Develop response plans for fires, chemical spills, severe weather, medical emergencies, and other reasonably foreseeable events. Plans should specify roles, communication protocols, evacuation procedures, and recovery steps.

Conduct emergency drills regularly. Drills reveal gaps in plans and build muscle memory for actual events. Debrief after each drill to identify improvement opportunities.

Maintain emergency equipment and supplies. Inspect fire extinguishers, first aid kits, spill response materials, and emergency communications equipment on scheduled intervals. Document inspections and promptly address deficiencies.

Step 5: Build Training and Communication Systems

Controls designed and procedures documented, effective implementation requires trained, informed workers. This step ensures your workforce has the knowledge and skills to work safely.

Designing Effective Safety Training Programs

Start with comprehensive new employee orientation. Cover general workplace hazards, emergency procedures, incident reporting requirements, and their rights and responsibilities. Orientation establishes safety expectations from day one.

Provide job-specific training before workers perform high-risk tasks. Training should cover task hazards, required controls, proper equipment use, and emergency responses. Verify competence through practical demonstrations, not just written tests.

Implement refresher training on regular cycles. Annual refreshers work for most topics. More frequent training may be needed for infrequently performed high-risk tasks or after incidents reveal knowledge gaps.

Train supervisors on their safety leadership responsibilities. They need skills in hazard recognition, incident investigation, safety coaching, and enforcement of safe work practices. Supervisor training often receives insufficient attention despite its critical importance.

Creating Communication Channels and Reporting Systems

Establish clear channels for safety communication flowing both directions. Management needs ways to share safety information, policy updates, and performance results. Workers need accessible methods to report hazards, near-misses, and concerns.

Regular safety meetings maintain focus and visibility. Toolbox talks address specific topics in brief sessions. Safety committee meetings engage worker representatives in program oversight. Management reviews assess program effectiveness and set improvement priorities.

Implement accessible incident reporting systems. Make reporting simple and emphasise learning over blame. Investigate all incidents and near-misses to identify root causes. Share lessons learned across the organisation to prevent recurrence.

Communication systems should enable two-way dialogue, not just top-down directives. Workers are more likely to report concerns when they see their input valued and acted upon.

Step 6: Establish Monitoring and Evaluation Processes

Implementing Performance Monitoring Systems

Track both leading and lagging safety indicators consistently. Lagging indicators like injury frequency rates show results. Leading indicators like inspection completion rates, training participation, and hazard reports filed predict future performance.

Establish regular reporting cycles. Monthly reports track tactical performance and identify emerging trends. Quarterly reviews assess progress toward objectives. Annual assessments evaluate overall program effectiveness and guide strategic improvements.

Use dashboards and visual management tools to make performance visible. Display current metrics in work areas. Trend charts show whether performance is improving, stable, or declining. Visibility drives accountability and engagement.

Conducting Safety Audits and Inspections

Regular audits verify SMS implementation and effectiveness. Internal audits assess compliance with procedures, identify gaps, and drive corrective actions. Schedule audits systematically to cover all operations over defined periods.

Workplace inspections identify hazards and verify control effectiveness. Scheduled inspections follow checklists covering common hazards. Focused inspections target specific concerns or high-risk areas. Document findings and track corrections to closure.

Third-party audits provide external validation. Independent auditors bring fresh perspectives and benchmark against industry practices. External audits also demonstrate due diligence to regulators, insurers, and customers.

Investigating Incidents and Near-Misses

Every incident and near-miss offers learning opportunities. Investigate not just what happened, but why it happened. Root cause analysis reveals system failures, not just individual errors.

Use structured investigation methods. The 5 Whys technique digs beyond surface causes. Fishbone diagrams map contributing factors across multiple categories. Timeline analysis reconstructs event sequences to identify failure points.

Focus investigations on system improvements, not blame assignment. What barriers failed or were missing? What controls need strengthening? How can we prevent recurrence? Share investigation findings and corrective actions across the organisation.

Driving Continuous Improvement Through Plan-Do-Check-Act

Planning Improvements Based on Data

Monitoring and evaluation generate improvement opportunities. Now implement the Plan-Do-Check-Act cycle to drive ongoing SMS enhancement.

Analyse performance data to identify improvement priorities. Where do incident patterns suggest control gaps? Which leading indicators lag behind targets? What audit findings reveal systemic issues?

Develop specific improvement plans. Define the problem clearly. Set measurable improvement targets. Identify required resources. Assign responsibility and establish timelines. Document the plan before implementation begins.

Prioritise improvements based on risk reduction potential and implementation feasibility. Quick wins build momentum while longer-term projects address complex systemic issues.

Implementing and Testing Changes

Execute improvement plans systematically. Communicate changes to affected workers before implementation. Provide necessary training on new procedures or controls. Monitor implementation closely during initial rollout.

Test improvements on a small scale when possible. Pilot programs reveal unforeseen issues before organisation-wide deployment. Gather feedback from workers using new procedures or controls. Refine based on lessons learned.

Document changes to procedures, training materials, and other SMS elements. Version control ensures everyone works from current information. Communication prevents confusion about what practices apply.

Checking Results and Standardising Success

Evaluate whether improvements achieved intended results. Compare post-implementation data against baseline performance. Did incident rates decline? Did hazard reports increase? Do audit scores show improvement?

When improvements prove effective, standardise them across similar operations. Update standard procedures to reflect improved practices. Share successes throughout the organisation to encourage adoption.

When improvements fall short, analyse why. Was the root cause misidentified? Were controls inadequately implemented? Did unforeseen factors interfere? Learn from both successes and setbacks to strengthen future improvement efforts.

Acting to Sustain and Expand Improvements

Successful improvements become the new baseline for future enhancement. The PDCA cycle never truly ends. Each improvement creates opportunity to identify the next enhancement target.

Maintain improvement momentum through regular management reviews. Quarterly meetings assess progress, remove barriers, and align safety improvement with broader business objectives. Executive participation reinforces that safety improvement is ongoing business practice, not a one-time project.

Recognise and celebrate improvement achievements. Acknowledge teams and individuals who drive safety enhancements. Recognition reinforces desired behaviours and maintains engagement in continuous improvement.

Key Questions About Safety Management System Implementation

How do you implement a safety management system?

Implementing a safety management system requires establishing a clear safety policy, conducting hazard identification and risk assessments, developing procedures and controls, providing training, and regularly monitoring and improving safety performance. Management commitment and employee involvement prove essential throughout the entire process.

What are the 5 elements of a safety management system?

The five elements are management commitment and employee involvement, worksite analysis to identify hazards, hazard prevention and control measures, safety and health training for all staff, and ongoing evaluation and improvement of the system. These elements create a framework for systematically reducing workplace risks.

How long does SMS implementation typically take?

Complete SMS implementation typically spans 12 to 24 months depending on organisation size, complexity, and existing safety infrastructure. Phased approaches with early quick wins help build momentum while addressing complex systemic changes over longer timeframes.

What regulatory standards govern safety management systems?

OSHA provides guidelines for workplace safety management in the United States. ISO 45001 offers an international standard for occupational health and safety management systems. Many industries have sector-specific regulations addressing safety management requirements applicable to their operations.

How do you maintain employee engagement in SMS over time?

Sustained engagement requires visible management commitment, accessible reporting channels, prompt response to concerns, regular communication about safety performance and improvements, meaningful participation opportunities, and recognition of safety contributions. Workers engage when they see their input valued and acted upon consistently.