Transportation safety challenges cost the industry billions annually and put lives at risk across every operational area. From driver behaviour to vehicle condition, cargo security to environmental hazards, safety incidents occur when multiple risk factors align without adequate control measures. These challenges aren’t isolated problems but interconnected vulnerabilities that demand systematic attention across your entire supply chain.

Understanding these challenges means recognising that transportation safety isn’t just about preventing individual incidents. It’s about building resilient systems that protect drivers, cargo, infrastructure, and the broader community.

Each safety challenge presents operational risks that extend beyond immediate physical harm. Poor safety performance affects insurance premiums, regulatory compliance status, customer relationships, and workforce morale. The transportation industry faces scrutiny from multiple regulatory bodies, and businesses operating heavy vehicles must demonstrate proactive safety management across all parties in the supply chain.

After 25 years working across FMCG supply chains in Australia and the UK, I’ve observed that the most effective safety programs address multiple challenges simultaneously through integrated systems rather than reactive fixes. Organizations that transform compliance from a legal obligation into operational advantage typically focus on sustainable tools, clear accountabilities, and practical implementation that works in daily operations.

This article examines the most significant safety challenges affecting the transportation industry today. You’ll find detailed analysis of human factors, equipment integrity, environmental conditions, and systemic vulnerabilities that contribute to safety incidents. More importantly, you’ll discover practical control measures and implementation strategies that address root causes rather than symptoms.

Driver Fatigue and Hours of Service Management

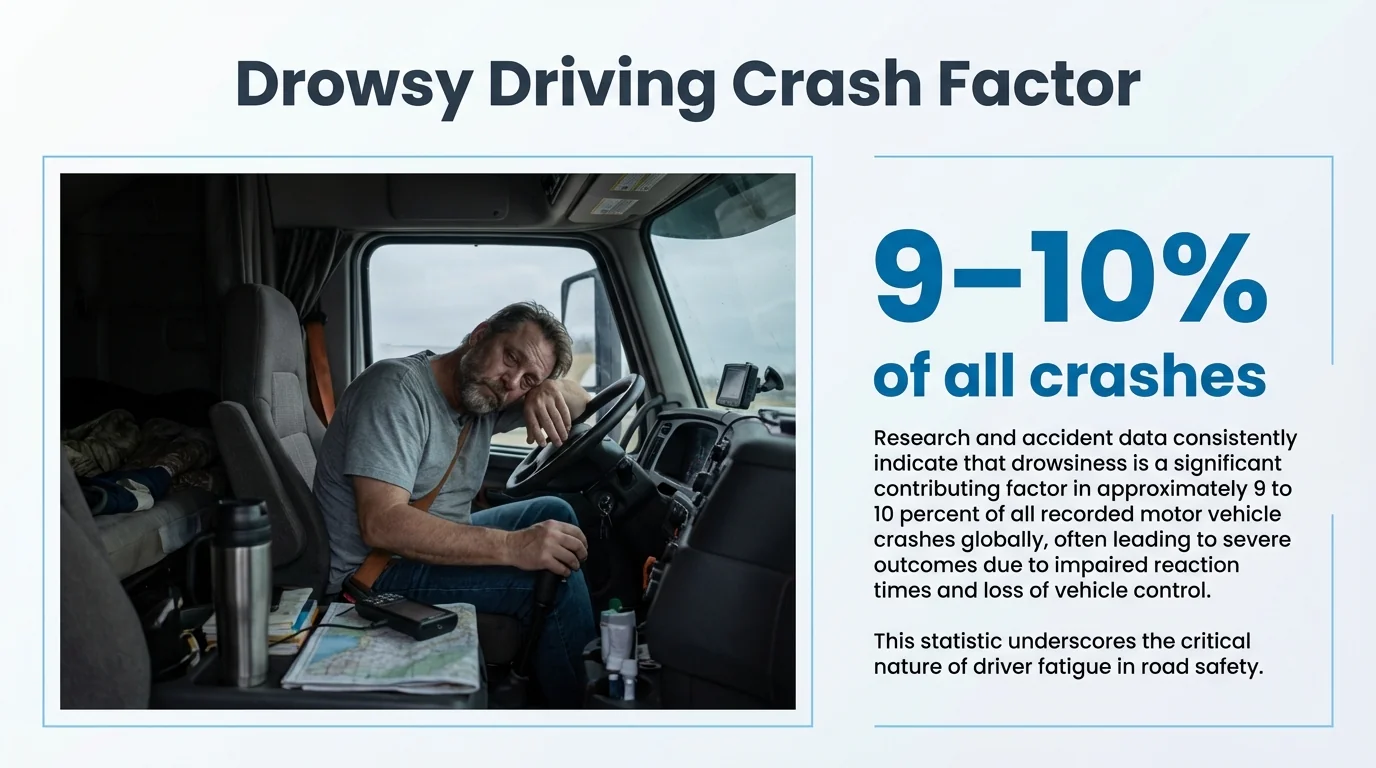

Driver Fatigue represents one of the most significant and persistent safety challenges in transportation. A naturalistic driving study estimated that drowsiness is a factor in up to 9–10% of all crashes, demonstrating the widespread impact of fatigue-related incidents.

Fatigue impairs reaction time, decision-making ability, and situational awareness. Drivers experiencing fatigue exhibit similar impairment levels to drivers under the influence of alcohol, yet fatigue remains harder to detect and measure objectively.

The physiological effects of fatigue accumulate over time. Extended driving periods without adequate rest disrupt circadian rhythms and reduce cognitive function. This deterioration affects not just driving performance but also the driver’s ability to recognize their own impairment level.

Hours of Service Compliance Challenges

Regulatory frameworks establish maximum driving hours and minimum rest requirements, but compliance presents ongoing challenges. Pressure to meet delivery schedules, inadequate trip planning, and insufficient understanding of fatigue management contribute to violations.

Electronic logging devices improve monitoring capability but cannot prevent fatigue itself. Technology tracks compliance with hour limits without addressing the underlying factors that contribute to driver exhaustion.

Effective fatigue management requires multiple control measures working together. Organizations need clear policies, robust scheduling systems, driver education programs, and workplace cultures that prioritize rest over schedule pressure.

Practical Fatigue Risk Mitigation

Implement fatigue risk management systems that go beyond minimum regulatory compliance. Schedule routes with realistic timeframes that account for traffic conditions, loading delays, and mandatory rest breaks.

Train schedulers and planners to recognize fatigue risk factors. Ensure your planning team understands that unrealistic schedules create pressure that drivers may respond to by sacrificing rest.

Establish clear communication channels where drivers can report fatigue concerns without fear of negative consequences. Your safety culture depends on drivers feeling empowered to stop driving when necessary.

Monitor for patterns that indicate systemic fatigue risks. Multiple drivers struggling to complete routes on time suggests scheduling issues rather than individual performance problems.

Distracted Driving and Attention Management

Distracted driving encompasses any activity that diverts attention from the primary task of vehicle operation. Mobile phones, in-cab technology, eating, adjusting controls, and external events all compete for driver attention.

The transportation industry faces unique distraction challenges. Commercial drivers operate larger vehicles requiring greater stopping distances, manage complex route information, and often face pressure to remain accessible through communication devices.

Distraction occurs in three forms: visual distraction takes eyes off the road, manual distraction involves hands leaving controls, and cognitive distraction diverts mental attention. The most dangerous activities combine all three types simultaneously.

Technology-Related Distractions

Mobile phone use presents the most documented distraction risk. Texting combines visual, manual, and cognitive distraction in a single activity that significantly increases collision risk.

However, in-cab technology designed to improve safety can paradoxically create distraction if poorly integrated. Complex navigation systems, electronic logging devices, and fleet management technology require driver interaction that may divert attention at critical moments.

Organizations must balance connectivity benefits against distraction risks. Clear policies regarding device use, proper technology integration, and driver training determine whether technology enhances or compromises safety.

Distraction Prevention Strategies

Establish explicit policies prohibiting mobile phone use while driving. Make compliance a non-negotiable safety requirement with clear consequences for violations.

Design communication protocols that minimize driver contact during trips. Use messaging systems that alert drivers to pull over safely before responding rather than expecting immediate replies.

Ensure all in-cab technology is properly mounted and positioned. Drivers should access controls without significantly redirecting visual attention or reaching across the cab.

Conduct regular training on attention management techniques. Help drivers recognize distraction risks and develop habits that maintain focus on the road environment.

Consider implementing driver monitoring technology that can detect attention lapses and provide real-time feedback.

Vehicle Collisions and Road Incidents

Vehicle collisions represent the most visible transportation safety challenge, resulting in property damage, injuries, operational disruption, and regulatory scrutiny. Understanding collision causes enables targeted prevention strategies.

Collisions rarely result from single causes. Most incidents involve multiple contributing factors including driver behaviour, vehicle condition, road environment, and operational pressures that combine to create critical situations.

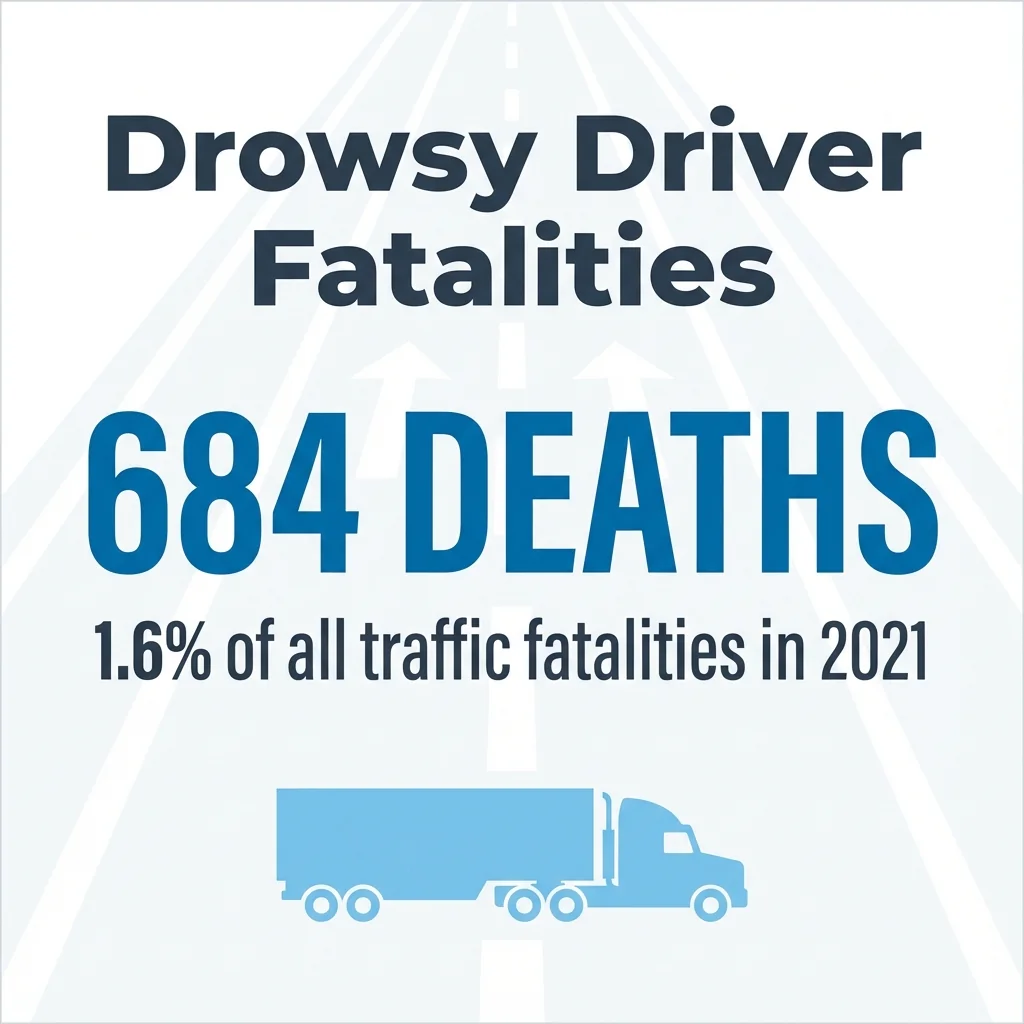

In 2021, NHTSA found that 684 people died in crashes involving a drowsy driver, about 1.6% of all motor-vehicle traffic crash fatalities, highlighting how human factors contribute significantly to collision risk.

Common Collision Scenarios

Rear-end collisions often result from inadequate following distance, particularly when drivers fail to adjust spacing for vehicle size, load weight, and road conditions. Heavy vehicles require significantly greater stopping distances than passenger cars.

Intersection incidents occur when drivers misjudge gaps, fail to yield appropriately, or proceed through controlled intersections without ensuring clearance. These scenarios frequently involve complex decision-making under time pressure.

Lane departure incidents stem from momentary inattention, fatigue, or misjudgment of vehicle position. These collisions may involve other vehicles, roadside infrastructure, or result in rollover incidents.

Collision Prevention Approaches

Develop detailed collision prevention strategies that address both immediate causation and underlying systemic factors contributing to incidents.

Implement defensive driving training focused on hazard recognition, space management, and decision-making under operational pressure. Effective training goes beyond basic vehicle control to develop advanced situational awareness.

Conduct thorough collision investigations that identify root causes rather than simply assigning blame. Use findings to improve systems, procedures, and training programs.

Analyze collision data for patterns indicating systemic issues. Multiple incidents involving similar circumstances suggest organizational factors requiring attention beyond individual driver coaching.

| Collision Type | Primary Contributing Factors | Prevention Focus |

|---|---|---|

| Rear-end impacts | Following distance, attention, speed management | Space cushion maintenance, hazard scanning |

| Intersection incidents | Gap judgment, yielding, visibility | Decision-making protocols, approach speed |

| Lane departures | Fatigue, distraction, over-correction | Attention management, gentle steering inputs |

| Backing incidents | Limited visibility, environmental awareness | Get-out-and-look protocols, spotter use |

Slips, Trips, and Falls in Transportation Operations

Slips, trips, and falls cause significant workplace injuries in transportation operations. These incidents occur during vehicle entry and exit, cargo handling, vehicle inspections, and movement around operational areas.

The transportation environment presents numerous hazards. Wet or contaminated surfaces, uneven ground, inadequate lighting, cluttered walkways, and weather conditions all contribute to slip and fall risks.

Many transportation workers underestimate slip and fall risks compared to vehicle operation hazards. This perception leads to inadequate attention to housekeeping, proper footwear, and safe movement practices.

High-Risk Activities and Locations

Vehicle entry and exit present elevated fall risks, particularly with commercial trucks and trailers. Cab access often requires climbing while carrying items or wearing bulky clothing that restricts movement.

Trailer access for load inspection or cargo securing requires working at height on potentially slippery surfaces. Weather conditions exacerbate these risks when surfaces become wet, icy, or contaminated with cargo residue.

Loading dock areas concentrate slip and fall hazards. Transitions between different surface levels, vehicle movement, cargo handling equipment operation, and varied weather protection create complex risk environments.

Slip and Fall Prevention Measures

Conduct regular workplace inspections identifying slip, trip, and fall hazards. Address uneven surfaces, poor lighting, and inadequate drainage that contribute to incidents.

Establish clear housekeeping standards for all operational areas. Require immediate cleanup of spills, organized storage that keeps walkways clear, and removal of tripping hazards.

Provide appropriate personal protective equipment including footwear with adequate grip for the working environment. Replace worn footwear before tread deterioration compromises traction.

Train workers on three-point contact techniques for vehicle access. Ensure drivers understand proper mounting and dismounting procedures that maintain stability throughout the movement.

Install and maintain proper handholds, steps, and access points on all vehicles and equipment. Regular inspection ensures these safety features remain functional and properly positioned.

Vehicle Maintenance Failures and Equipment Integrity

Vehicle maintenance directly affects safety performance. Mechanical failures can cause collisions, breakdowns in dangerous locations, cargo loss, and environmental incidents.

The transportation industry operates under regulatory requirements for vehicle maintenance, but compliance represents minimum standards. Effective maintenance programs exceed regulatory minimums to prevent failures before they occur.

Deferred maintenance creates cascading problems. Small issues that seem insignificant often indicate larger problems or quickly develop into serious failures if left unaddressed.

Critical Maintenance Areas

Brake system integrity represents the most critical safety component. Regular inspection, adjustment, and replacement of brake components prevent failures that directly compromise stopping ability.

Tire condition affects vehicle control, fuel efficiency, and collision risk. Proper inflation, adequate tread depth, and absence of damage ensure tires perform as designed under varied conditions.

Steering and suspension components determine vehicle handling characteristics. Worn components reduce control, particularly during emergency maneuvers or adverse conditions.

Lighting and visibility systems enable safe operation during all conditions. Functional headlights, taillights, turn signals, and reflective markings ensure vehicles remain visible and can adequately illuminate road environments.

Implementing Effective Maintenance Systems

Develop preventive maintenance schedules based on manufacturer recommendations, operational conditions, and regulatory requirements. Document all maintenance activities to demonstrate compliance and track vehicle history.

Establish clear defect reporting procedures that drivers understand and use consistently. Create non-punitive reporting environments where identifying problems is valued over hiding issues.

Conduct thorough pre-trip inspections covering all critical safety systems. Train drivers to recognize defects requiring immediate attention versus issues permitting operation until scheduled maintenance.

Remove defective vehicles from service until repairs are completed. Resist operational pressure to continue using equipment with known safety defects.

Maintain detailed records demonstrating maintenance program effectiveness. Use data to identify recurring problems indicating design issues or operational factors accelerating component wear.

Cargo Handling, Loading, and Securing Challenges

Cargo handling presents multiple safety challenges throughout the loading, transport, and unloading process. Improper practices create risks for workers, drivers, other road users, and cargo integrity.

Load securement directly affects vehicle stability and control. Inadequately secured cargo can shift during transport, creating unbalanced loads that make vehicles difficult to control or cause cargo loss onto roadways.

Loading and unloading operations involve heavy materials, powered equipment, and coordinated activities in congested areas. These conditions create opportunities for crushing injuries, falls, and struck-by incidents.

Load Securement Requirements

Regulatory standards specify minimum load securement requirements including restraint ratings, securing point locations, and securement patterns for different cargo types. Compliance requires understanding these standards and applying them correctly.

Weight distribution affects vehicle handling and brake effectiveness. Properly distributed loads maintain correct axle weights while preventing excessive stress on vehicle components.

Securement equipment must be rated for the loads being restrained and maintained in serviceable condition. Damaged straps, chains, or tie-downs may fail under load, releasing cargo during transport.

Safe Cargo Handling Practices

Conduct load planning before arriving at loading facilities. Understand cargo characteristics, required securement methods, and weight distribution requirements.

Inspect cargo and securement before departure and at regular intervals during trips. Check that loads haven’t shifted and securement devices remain properly tensioned.

Use appropriate equipment for loading and unloading activities. Forklifts, pallet jacks, and lifting devices must be rated for the loads being handled and operated by trained personnel.

Establish clear communication protocols for loading areas. Ensure all personnel understand vehicle movement patterns, loading sequences, and hazard zones around operating equipment.

Train drivers on proper securement techniques for the cargo types they typically transport. Generic training may not address specific challenges presented by particular load configurations.

Weather-Related Hazards and Environmental Conditions

Weather conditions significantly affect transportation safety. Rain, snow, ice, fog, wind, and extreme temperatures create hazards requiring operational adjustments to maintain safe operations.

Weather-related incidents often result from failure to adequately adjust driving behavior for changed conditions. Speed appropriate for dry pavement may be excessive for wet or icy surfaces.

Transportation operations cannot simply cease during adverse weather. The industry must develop capabilities to operate safely across varied conditions while recognizing when conditions exceed safe operational limits.

Specific Weather Challenges

Reduced visibility from fog, heavy rain, or snow affects hazard detection and following distance judgment. Drivers must reduce speed to maintain stopping capability within visible distance.

Reduced traction on wet, icy, or snow-covered surfaces extends stopping distances and reduces vehicle control. These conditions require gentler inputs for steering, acceleration, and braking.

High winds affect large vehicles disproportionately. Empty trailers, in particular, present large surface areas that strong crosswinds can push significantly, requiring constant steering corrections.

Extreme temperatures affect both vehicle systems and driver performance. Cold weather impacts battery capacity, fuel gelling, and tire pressure. Heat creates fatigue risks and can cause tire failures.

Weather Risk Management Strategies

Monitor weather forecasts and alerts for planned routes. Adjust schedules when conditions warrant or identify alternative routes avoiding the worst conditions.

Train drivers on vehicle control techniques appropriate for different weather conditions. Ensure they understand how weather affects stopping distances, traction limits, and visibility requirements.

Establish clear criteria for when conditions exceed safe operational parameters. Empower drivers to delay or suspend trips when weather creates unacceptable risks.

Ensure vehicles are properly equipped for expected conditions. Appropriate tires, functional heating and cooling systems, and adequate windshield washer fluid maintain basic operational capability.

Communicate realistic timeframes that account for weather-related delays. Reduce schedule pressure that might encourage drivers to operate faster than conditions safely allow.

Inadequate Safety Training and Skill Development

Safety training provides the foundation for all other safety initiatives. Without adequate training, drivers and other transportation workers cannot effectively identify hazards, follow proper procedures, or respond appropriately to challenging situations.

Training requirements vary by jurisdiction and vehicle type. However, minimum regulatory training often proves insufficient for complex operational environments and evolving safety challenges.

Effective training extends beyond initial qualification. Ongoing development addressing new equipment, procedures, regulations, and lessons learned from incidents maintains and improves workforce capability.

Training Program Components

Technical skill development ensures workers can properly operate equipment, perform required inspections, and execute standard procedures. This foundation enables safe performance of routine tasks.

Hazard recognition training develops the ability to identify risks before they result in incidents. Workers who effectively scan environments and recognize hazard patterns can implement preventive actions.

Decision-making under pressure prepares workers for non-routine situations requiring judgment. Scenario-based training develops thinking skills that apply across varied circumstances.

Regulatory compliance training ensures workers understand applicable requirements and the rationale behind safety rules. Understanding improves voluntary compliance beyond minimum standards.

Building Effective Training Systems

Develop comprehensive safety training programs addressing both initial qualification and ongoing development throughout employment.

Use varied training methods including classroom instruction, hands-on practice, simulation, and mentoring. Different content types require different delivery approaches for effective learning.

Assess training effectiveness through testing, observation, and performance monitoring. Ensure workers can actually apply learned skills rather than simply completing training hours.

Update training content regularly based on incident investigations, regulatory changes, and operational modifications. Keep material current and relevant to actual work conditions.

Document all training activities comprehensively. Maintain records demonstrating each worker’s qualification for their assigned tasks and ongoing development participation.

Human Error and Behavioral Risk Factors

Human factors contribute to the majority of transportation safety incidents. Understanding how human capabilities, limitations, and behaviors affect safety enables more effective risk management.

Human error rarely results from simple carelessness. Most errors occur when workplace design, procedures, or organizational factors create conditions where mistakes become likely despite good intentions.

Behavioral safety addresses the choices workers make regarding risk-taking, shortcut adoption, and procedure compliance. These decisions reflect individual attitudes, workplace culture, and organizational priorities.

Common Human Factor Challenges

Time pressure creates conditions encouraging shortcuts and procedure violations. When schedule demands conflict with safety requirements, workers face difficult decisions about priorities.

Complacency develops when familiar tasks become routine. Workers may reduce attention to detail or skip steps in procedures they’ve performed successfully many times without incident.

Inadequate communication creates misunderstandings about expectations, procedures, and responsibilities. Clear communication becomes increasingly challenging in complex operations involving multiple parties.

Physical and mental health directly affect safety performance. Medical conditions, medications, stress, and personal problems can impair judgment and reaction time.

Addressing Human Factors Systematically

Design work systems accounting for normal human capabilities and limitations. Don’t rely on perfect performance under all conditions to prevent incidents.

Implement safety management systems that address organizational factors contributing to human error. Look beyond individual mistakes to system-level causes.

Develop workplace cultures where safety genuinely comes before schedule or cost considerations. Worker decisions reflect the priorities they observe leadership actually demonstrating.

Establish confidential reporting systems allowing workers to report errors, near-misses, and safety concerns without fear of punishment. Learning from mistakes requires willingness to acknowledge them.

Conduct investigations focused on understanding why errors occurred rather than assigning blame. Root cause analysis reveals systemic improvements preventing future incidents.

Workplace Violence and Operator Assault Risks

Transportation workers face risks of workplace violence and assault, particularly those interacting with the public or working in isolated environments. These security challenges require specific attention within safety programs.

Public transit operators experience elevated assault risks during confrontations with passengers. Disputes over fares, route deviations, or scheduling issues can escalate to violence.

Long-haul truck drivers working alone in varied locations face risks from theft attempts, hijackings, or random violence. Parking in unsecured areas during rest periods creates vulnerability.

Violence Prevention Strategies

Conduct risk assessments identifying roles and locations with elevated violence potential. Implement targeted controls addressing specific threats rather than generic security measures.

Provide conflict de-escalation training for workers in customer-facing roles. Teach techniques for managing difficult interactions before they become physical confrontations.

Design physical work environments to reduce violence risks. Install barriers separating drivers from passengers, improve lighting in parking areas, and position workers where they remain visible.

Establish clear procedures for responding to threats or violent situations. Ensure workers know how to summon help and when personal safety justifies abandoning vehicles or cargo.

Report all violence incidents to authorities and conduct internal reviews. Track patterns indicating locations or situations requiring additional security measures.

Infrastructure and Operational Environment Hazards

Transportation infrastructure presents numerous hazards affecting safe operations. Road conditions, facility design, and operational environments create risks requiring careful management.

Deteriorating infrastructure increases incident risk. Potholes, uneven pavement, unclear markings, and inadequate signage force drivers to make rapid adjustments that may contribute to loss of control.

Facility design at customer locations affects safety during loading and unloading operations. Tight spaces, poor sight lines, mixed pedestrian and vehicle traffic, and inadequate lighting create hazardous conditions.

Managing Infrastructure Risks

Conduct route assessments identifying infrastructure hazards along regular travel corridors. Share information with drivers regarding known problem areas requiring extra attention.

Evaluate customer facilities before dispatch. Identify locations with challenging access, limited maneuvering space, or other safety concerns requiring special procedures.

Report infrastructure defects to responsible authorities. While organizations cannot control public infrastructure, reporting helps prioritize maintenance and creates documentation if incidents occur.

Develop specific procedures for challenging locations. Provide drivers with site-specific instructions, diagrams, or special equipment needed for safe operations at difficult facilities.

Hazardous Materials Transportation Risks

Transporting dangerous goods creates additional safety challenges beyond general cargo. Hazardous materials present risks of fire, explosion, toxic exposure, or environmental contamination if released.

Specialized regulatory frameworks govern dangerous goods transport. Compliance requires understanding classification systems, packaging requirements, documentation, placarding, emergency response information, and driver qualifications.

Small quantities of hazardous materials appear in many supply chains. Organizations may transport dangerous goods without fully recognizing the regulatory requirements or associated risks.

Dangerous Goods Safety Requirements

Properly classify all materials according to dangerous goods regulations. Incorrect classification leads to inappropriate packaging, handling, and emergency response preparation.

Ensure all hazardous materials are packaged in approved containers meeting regulatory specifications. Packaging prevents releases during normal transport and minor incidents.

Verify drivers hold appropriate dangerous goods qualifications. Training requirements vary based on the types and quantities of hazardous materials being transported.

Maintain accurate documentation including shipping papers, emergency response information, and regulatory declarations. This information guides emergency responders if incidents occur.

Establish emergency response procedures for spills, releases, or incidents involving hazardous materials. Ensure affected personnel understand appropriate immediate actions and notification requirements.

Chain of Responsibility and Shared Accountability

Transportation safety extends beyond drivers to encompass all parties influencing transport operations. Chain of Responsibility frameworks recognize that schedulers, customers, loaders, and executives all affect safety outcomes.

Shared accountability ensures that parties creating safety pressures cannot insulate themselves from consequences. When schedulers set unrealistic timeframes or customers create loading delays, they contribute to subsequent safety incidents.

Organizations operating heavy vehicles must demonstrate reasonable steps to prevent breaches across their supply chains. This extends safety responsibilities throughout business operations, not just to driving activities.

Implementing Shared Accountability

Map all parties in your transport supply chain who influence safety outcomes. Identify customers, contractors, employees, and other stakeholders whose decisions affect safety performance.

Conduct gap assessments identifying where current systems fail to adequately manage safety responsibilities. Look for organizational blind spots where no one clearly owns specific safety risks.

Develop clear safety accountabilities throughout the organization. Ensure procurement teams, customer service representatives, and senior executives understand how their decisions affect safety.

Establish communication mechanisms enabling frontline workers to report safety pressures created by other parties. Create clear escalation procedures when schedule demands conflict with safety requirements.

Include safety requirements in contracts with customers and contractors. Specify expectations regarding scheduling practices, facility standards, and loading procedures that affect safety.

Building Resilient Safety Systems

Transportation safety challenges are interconnected rather than isolated. Effective safety management requires systematic approaches addressing multiple risk factors simultaneously.

No single solution eliminates all safety risks. Organizations need layered defenses combining engineering controls, administrative procedures, training, and protective equipment.

Safety systems must adapt as operations evolve. Regular review ensures control measures remain effective when facing new equipment, changed procedures, or different regulatory requirements.

After 25 years working across diverse supply chain environments, I’ve observed that sustainable safety improvement comes from integrating safety into normal business processes rather than treating it as separate compliance activity. Organizations achieving strong safety performance make it part of how they plan, operate, and make decisions.

The safety challenges outlined throughout this article represent significant risks requiring ongoing attention. However, they also present opportunities to build operational advantages through reduced incidents, lower insurance costs, improved regulatory relationships, and enhanced workforce engagement.

Start by honestly assessing where your organization stands regarding each challenge area. Identify gaps between current performance and desired outcomes. Prioritize improvements based on risk severity and implementation feasibility.

Effective safety management transforms regulatory obligations into operational strengths. The effort invested in addressing these challenges delivers returns through improved efficiency, reduced disruption, and protection of your most valuable assets, your people.