HVNL compliance best practices center on understanding your primary duty under the Chain of Responsibility framework and implementing systematic controls across five compliance areas: fatigue management, vehicle standards, mass and dimension limits, speed, and loading. Every party in the Chain of Responsibility has a positive duty to ensure, so far as is reasonably practicable, the safety of their activities in relation to a heavy vehicle. This extends beyond drivers to consignors, consignees, schedulers, loading managers, and operators who influence transport operations. The most effective compliance approach combines documented safety management systems, proactive risk assessment, verified control implementation, and continuous monitoring processes that adapt to operational changes.

Building robust HVNL compliance isn’t about ticking boxes to avoid penalties. It’s about creating operational systems that protect people while improving business efficiency.

Over 25 years in supply chain management has taught me one clear lesson: compliance systems fail when they’re built on paper rather than embedded in daily operations. The businesses that succeed integrate regulatory requirements into their existing workflows rather than treating compliance as a separate administrative burden.

This guide walks through the practical implementation of HVNL compliance requirements. You’ll understand the regulatory framework, identify your specific Chain of Responsibility obligations, and build verification systems that prove your due diligence. Each section builds on the previous one, moving from legal foundations through to operational implementation.

Understanding the Heavy Vehicle National Law Framework

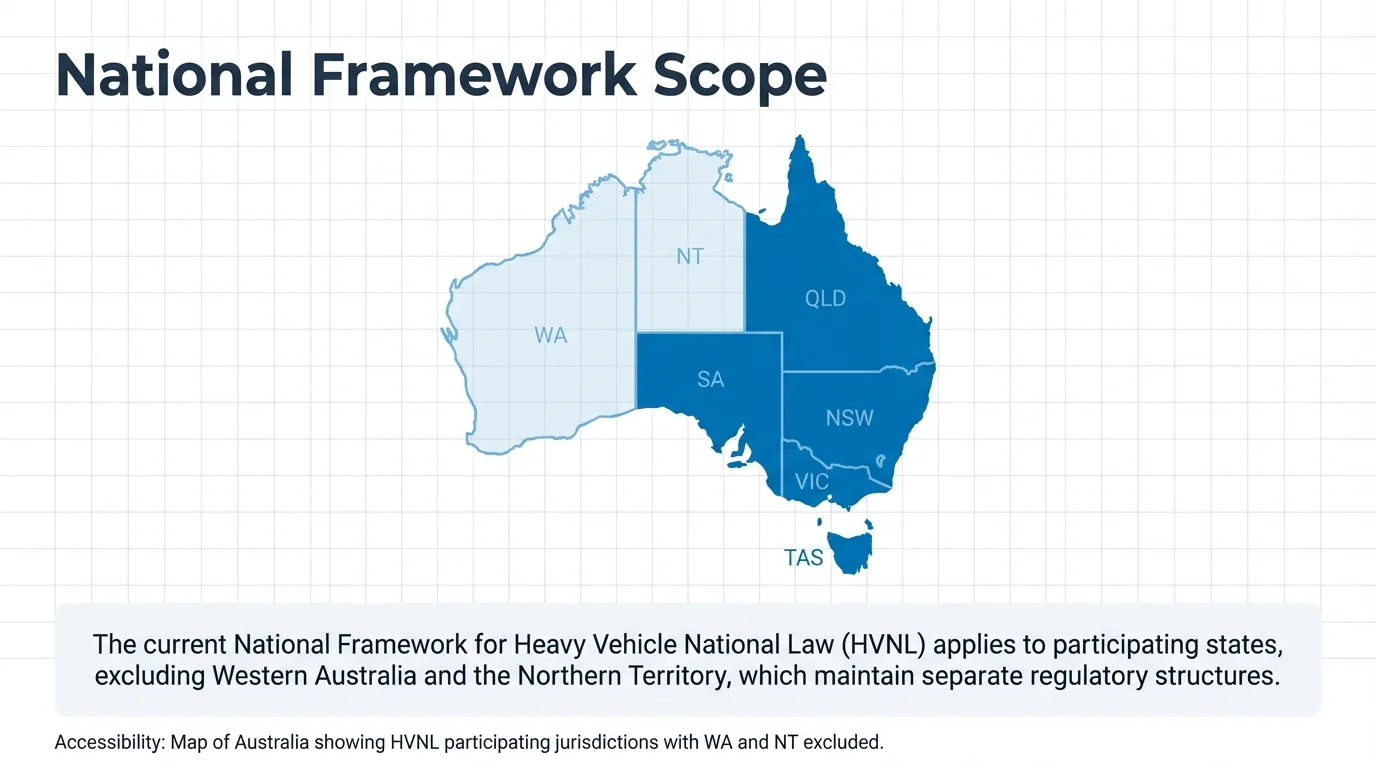

The Heavy Vehicle National Law is the primary legal framework governing the operation of heavy vehicles with a gross vehicle mass of more than 4.5 tonnes in participating Australian states and territories. It replaced previous state-based regulations to create national consistency in heavy vehicle operations.

The National Heavy Vehicle Regulator administers the HVNL and its associated regulations. Their role includes issuing permits and notices, conducting compliance activities, and providing guidance to industry participants.

The HVNL applies in all jurisdictions except Western Australia and the Northern Territory, where separate heavy vehicle laws continue to operate. Queensland serves as the host jurisdiction, with other states and territories adopting the law through their own legislation.

Recent HVNL Reform and What It Means

The HVNL underwent significant review starting in 2019 to modernize the regulatory framework. The 2025 Amendment Package was passed without amendment by the Queensland Parliament on 18 November 2025. These reforms aim to improve safety outcomes while reducing regulatory burden through clearer obligations and more flexible compliance pathways.

The amended HVNL is expected to commence in mid-2026. Transport operators should prepare for these changes by reviewing their current systems against the new requirements.

Core Regulatory Requirements Under HVNL

The HVNL establishes requirements across multiple compliance areas. Understanding these categories helps you structure your compliance approach systematically.

| Compliance Area | Primary Focus | Key Requirements |

|---|---|---|

| Fatigue Management | Driver work and rest hours | Work diaries, scheduling, monitoring |

| Vehicle Standards | Roadworthiness and maintenance | Inspections, defect management, records |

| Mass and Dimension | Weight and size limits | Load calculations, permits, restraint |

| Speed Compliance | Speed limit adherence | Speed limiters, monitoring, scheduling |

| Load Restraint | Securing cargo safely | Restraint methods, load stability, verification |

Unless otherwise exempted by a notice or permit, operators must ensure their vehicles comply with the Australian Design Rules, the HVNL, the Heavy Vehicle (Mass, Dimension and Loading) National Regulation, and the Heavy Vehicle (Vehicle Standards) National Regulation. This creates multiple layers of compliance that require coordinated management.

Chain of Responsibility: Shared Accountability Across the Supply Chain

Chain of Responsibility represents a fundamental shift from driver-only liability to shared accountability across everyone who influences transport operations. This approach recognizes that many factors contributing to heavy vehicle incidents originate outside the vehicle cabin.

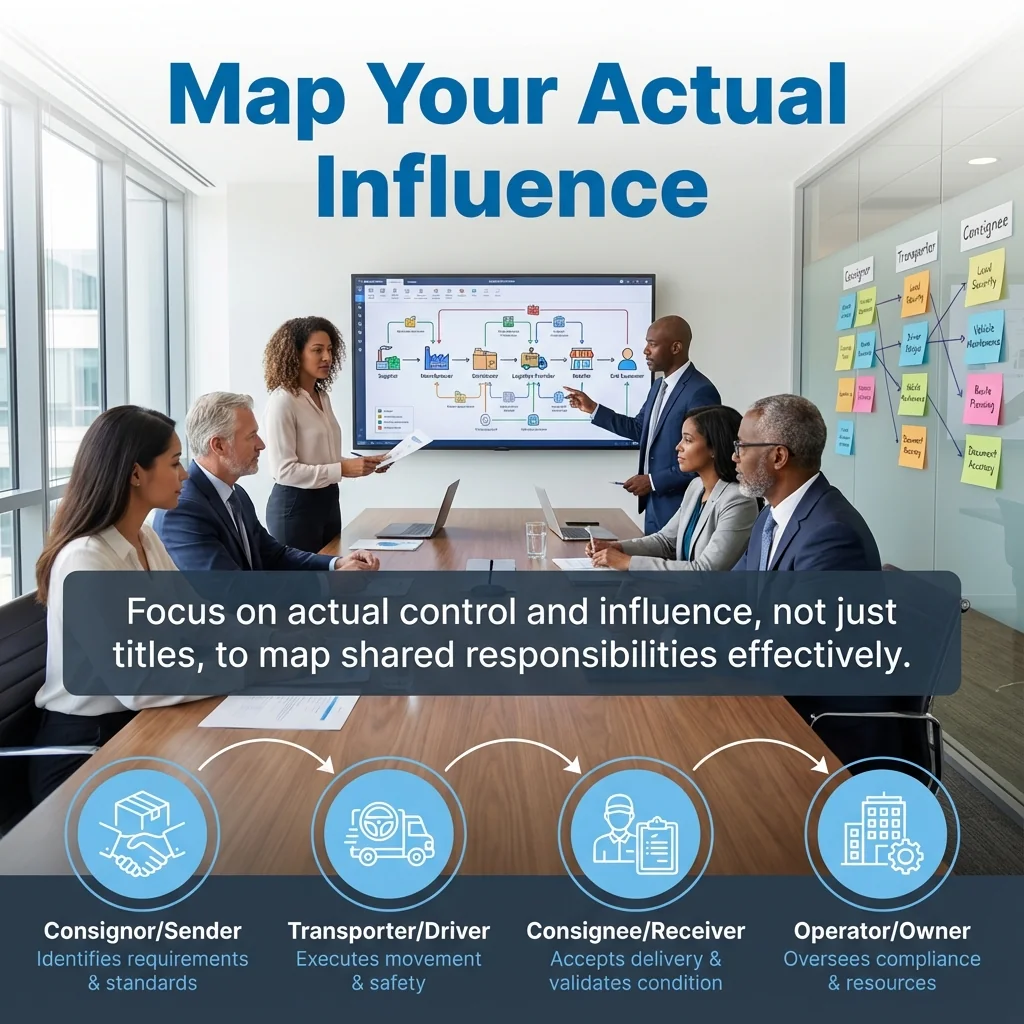

CoR parties include drivers, operators, schedulers, consignors, consignees, loading managers, and anyone else who exercises control or influence over transport activities. Each party holds responsibility for the elements they control.

The Primary Duty and Reasonably Practicable Standard

The primary duty requires each CoR party to ensure, so far as is reasonably practicable, the safety of their transport activities. This positive obligation extends beyond simply avoiding breaches to actively implementing safety measures.

“Reasonably practicable” considers what you knew or should have known about hazards, available control measures, and whether the cost of controls is proportionate to the risk. This standard means you can’t ignore known risks simply because controls require investment.

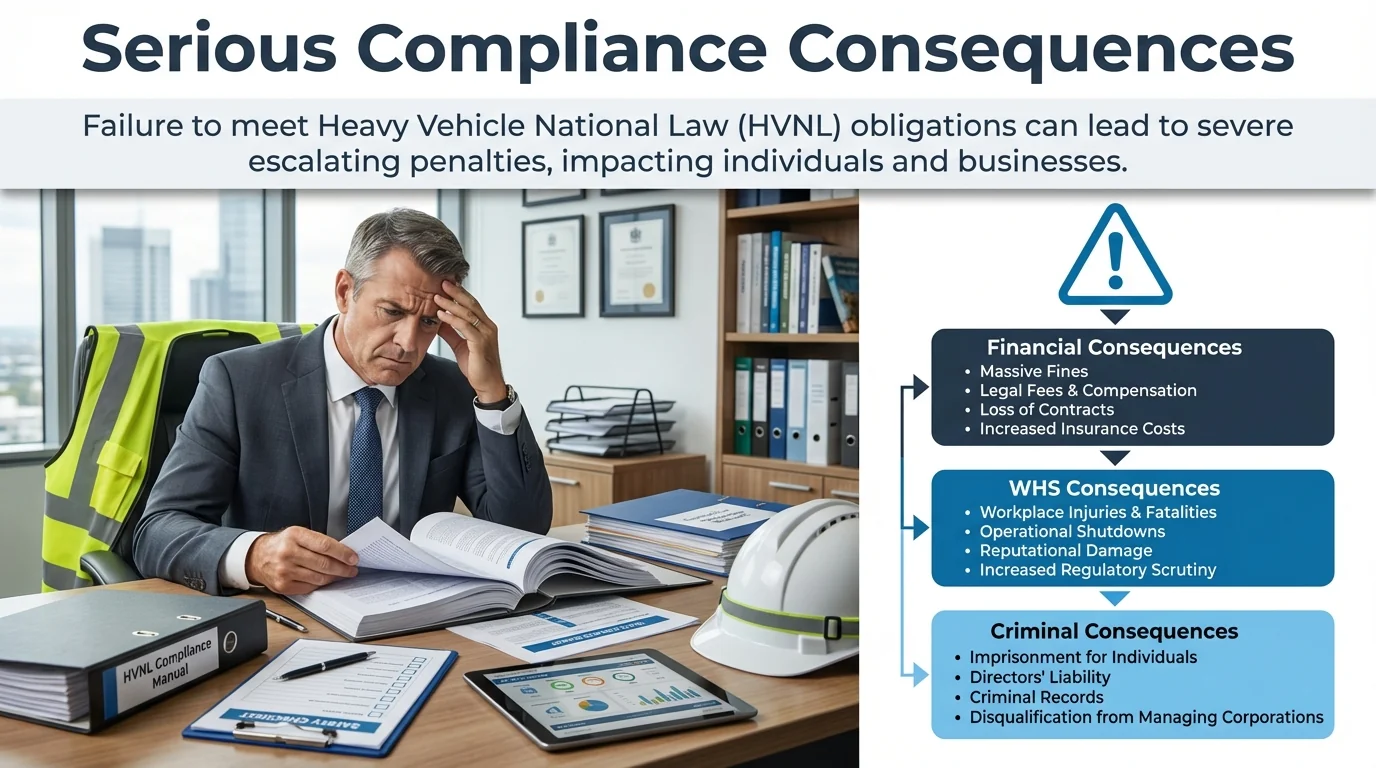

Non-compliance can lead to severe financial penalties, and breaches which contribute to serious safety incidents may also expose businesses and officers to work health and safety and criminal consequences. The stakes extend beyond administrative fines to potential personal liability for executive officers.

How CoR Obligations Flow Through Business Relationships

Consider a typical supply chain involving a manufacturer, freight forwarder, transport operator, and retailer. Each party’s actions influence whether the driver can comply with HVNL requirements.

- The manufacturer controls loading practices and departure times

- The freight forwarder sets delivery schedules and selects carriers

- The transport operator maintains vehicles and manages driver rosters

- The retailer specifies delivery windows and unloading procedures

- The driver executes the transport task within these constraints

CoR obligations extend to speed compliance, where parties who set schedules or payment structures that can only be met by speeding may be liable for associated breaches even if they never drive a vehicle themselves. This principle applies across all HVNL compliance areas.

Identifying Your CoR Obligations

Start by mapping your actual influence over transport activities. Don’t rely on contractual titles or job descriptions. Focus on what you actually control or direct.

Ask specific questions about your involvement. Do you specify delivery timeframes? Do you determine loading methods? Do you select or approve transport providers? Do you set freight rates that influence safety decisions?

Document your findings in a CoR responsibility matrix. List each transport activity in your supply chain, identify who influences it, and specify the nature of their control. This becomes your foundation for assigning compliance responsibilities.

Implementing Effective Due Diligence Processes

Due diligence under HVNL means taking reasonable steps to ensure your organization and its officers meet their primary duty. This goes beyond good intentions to documented, verifiable actions.

Executive officers face specific due diligence obligations. They must acquire and maintain knowledge of HVNL requirements, understand the nature of operations, ensure appropriate resources and processes exist, verify information about compliance, and ensure the organization has and uses systems to manage HVNL risks.

Building Your Due Diligence Evidence Base

Create documented evidence that demonstrates your proactive approach to compliance. This protects your organization and its officers while improving actual safety outcomes.

Your evidence should show you’ve identified obligations, assessed risks, implemented controls, monitored effectiveness, and responded to issues. Each element requires specific documentation.

| Due Diligence Element | Required Evidence | Review Frequency |

|---|---|---|

| Knowledge Acquisition | Training records, competency assessments, industry participation | Annual minimum |

| Risk Understanding | Risk assessments, incident analysis, operational reviews | Ongoing and annual |

| Resource Allocation | Budget approvals, system implementation, staffing decisions | Annual and as needed |

| Compliance Verification | Audit reports, monitoring data, breach investigations | Monthly to quarterly |

| System Effectiveness | Performance metrics, corrective actions, continuous improvement | Quarterly minimum |

Conducting Regular Compliance Reviews

Schedule quarterly reviews of your HVNL compliance status. Examine recent incidents, audit findings, monitoring results, and changes to operations or regulations.

Involve your executive team in these reviews. Their direct participation demonstrates due diligence and ensures compliance issues receive appropriate attention and resources.

Document review outcomes, decisions made, and actions assigned. This record proves your systematic approach to maintaining compliance over time.

Essential HVNL Compliance Checklist for Transport Operations

A structured compliance checklist helps verify that all HVNL requirements receive attention across your operations. This section provides the framework for building your verification system.

Tailor this checklist to your specific role in the Chain of Responsibility. Not every element applies to every party, but you must address the areas you influence or control.

Pre-Trip Verification Requirements

Before any journey begins, verify that fundamental compliance requirements are met. These checks prevent many common breaches.

- Confirm the driver holds appropriate licensing for the vehicle class

- Verify the driver has adequate rest and hasn’t exceeded work hour limits

- Check the vehicle’s registration and any required permits are current

- Ensure the vehicle passed its pre-start inspection with no critical defects

- Confirm the load doesn’t exceed mass limits and is properly restrained

- Verify the journey can be completed within work hour limits

- Check speed limiter settings match regulatory requirements

Operational Monitoring Points

During operations, maintain visibility of compliance status. Don’t wait for audits or incidents to identify problems.

Monitor work diary compliance daily. Review electronic work diary data for missed entries, unusual patterns, or approaching work hour limits. Address issues immediately rather than allowing them to accumulate.

Track vehicle inspection completion and defect reporting. Verify that identified defects receive appropriate attention based on their severity. Ensure critical defects ground vehicles until repaired.

Review journey progress against scheduled times. Identify situations where schedules may be pressuring drivers to speed or skip rest breaks. Adjust schedules proactively rather than forcing compliance breaches.

Documentation and Record Keeping Standards

HVNL requires retention of various records for specified periods. Missing records create compliance risks and limit your ability to demonstrate due diligence.

Maintain work diaries or electronic work diary data for three years. Keep vehicle maintenance records including inspection reports, repair documentation, and defect registers. Retain training records showing driver and staff competency in relevant areas.

Store load documentation including consignment notes, loading plans, and restraint calculations. Keep permit copies and variation notices applicable to your operations. Document your risk assessments, safety procedures, and compliance verification activities.

Implement a document management system that ensures records remain accessible, protected from loss, and retrievable when needed for audits or investigations.

Fatigue Management Compliance: Work and Rest Hours

Fatigue management represents one of the most regulated areas under HVNL. The requirements recognize that driver fatigue significantly contributes to heavy vehicle incidents.

HVNL provides three fatigue management options: Standard Hours, Basic Fatigue Management, and Advanced Fatigue Management. Each option involves different work and rest hour limits with varying flexibility and compliance requirements.

Understanding Work and Rest Hour Requirements

Standard Hours apply unless you operate under an approved BFM or AFM system. These set maximum work hours and minimum rest breaks across different timeframes.

Drivers under Standard Hours can work maximum 12 hours in any 24-hour period, 72 hours in any 7 consecutive days, and 144 hours in any 14 consecutive days. They must take minimum 7 continuous hours rest in every 24-hour period and 24 continuous hours rest in every 7 days.

These limits require careful journey planning and scheduling. You can’t simply maximize every period. The rolling timeframes mean yesterday’s hours affect today’s available work time.

Electronic Work Diary Implementation

Electronic Work Diaries replace paper work diaries for fatigue recording. They automate time recording, reduce errors, and enable real-time monitoring of driver hours.

Approved EWD systems must meet technical standards set by NHVR. They automatically record vehicle movement, prompt drivers to record activities, and prevent unauthorized editing of historical records.

Implement EWDs systematically. Select an approved provider, install devices correctly, train drivers thoroughly, and establish monitoring processes. Verify that your back-office systems can access and analyze EWD data effectively.

Monitor EWD compliance daily rather than reviewing records only when problems surface. Set alerts for approaching work hour limits, missing entries, or unusual patterns requiring investigation.

BFM and AFM Alternative Compliance Frameworks

Basic Fatigue Management and Advanced Fatigue Management offer alternatives to Standard Hours with different work hour limits and additional safeguards.

BFM requires an accredited system including fatigue management procedures, risk management processes, driver training, and record keeping. It allows slightly extended work hours with appropriate controls.

AFM provides the most flexibility but requires the most rigorous safety management. It’s suited to larger operations with sophisticated systems and resources to manage complex fatigue risks.

Evaluate whether BFM or AFM suits your operations. Consider your scheduling needs, operational complexity, and capacity to implement required safety systems. Don’t pursue flexibility without the capability to manage increased risks.

Vehicle Standards and Maintenance Requirements

Vehicle standards under HVNL ensure heavy vehicles remain roadworthy throughout their service life. These requirements extend beyond initial registration to ongoing maintenance and inspection obligations.

Parties responsible for vehicle standards include operators who manage vehicles, drivers who conduct pre-start checks, and anyone who modifies vehicles or influences maintenance decisions.

Pre-Trip Inspection Protocols

Drivers must conduct pre-start inspections before each journey. These checks identify defects that could affect safety or lead to breakdowns.

Inspections should cover braking systems, steering, lights, tires, load restraint equipment, and other safety-critical components. Use a standardized checklist aligned with the National Heavy Vehicle Inspection Manual.

Establish clear defect reporting procedures. Drivers must know how to report defects, what constitutes a minor versus major defect, and when a vehicle should be taken out of service.

Train drivers to recognize defects requiring immediate action. A critical brake defect can’t wait until the next scheduled service. Ensure drivers feel empowered to ground vehicles when safety demands it.

Maintenance Scheduling and Record Systems

Implement preventive maintenance schedules based on manufacturer recommendations, operating conditions, and regulatory requirements. Don’t rely solely on reactive repairs.

Schedule regular servicing at appropriate intervals. Track service history to identify recurring problems or components requiring more frequent attention. Adjust maintenance schedules based on actual vehicle performance and failure patterns.

Maintain detailed maintenance records showing what work was performed, when, by whom, and based on what inspection or schedule. Records prove your systematic approach to keeping vehicles roadworthy.

Verify that your maintenance providers understand HVNL requirements and heavy vehicle standards. Using a competent provider doesn’t eliminate your responsibility, but it supports compliance.

Managing Defects and Repairs

Not all defects require immediate vehicle grounding, but all require appropriate action. Establish a defect classification system that determines response requirements.

Minor defects might be scheduled for repair at the next service. Major defects require repair before the vehicle operates again. Critical defects demand immediate action and may require roadside repairs or towing.

Track defects through to completion. Don’t let reported defects disappear into an informal system of verbal handovers and memory. Use a defect register that shows identification, classification, action taken, and verification of repair.

Analyze defect patterns to identify systemic issues. Recurring problems with particular vehicles, components, or operating conditions indicate deeper issues requiring strategic attention.

Mass, Dimension, and Loading Compliance

Mass and dimension requirements prevent overloading and ensure vehicles operate within size limits appropriate for road infrastructure. Breaches create significant safety risks and infrastructure damage.

These requirements apply differently depending on vehicle configuration, axle arrangements, and route characteristics. General mass limits, Higher Mass Limits, and Concessional Mass Limits each involve specific conditions and requirements.

Load Calculation and Verification Methods

Calculate mass before loading, not after. Waiting until a vehicle is loaded to discover it’s overweight creates operational delays and compliance risks.

Know your vehicle’s tare weight accurately. Ensure recent weighbridge certificates confirm empty vehicle mass. Account for fuel, spare tires, and other items that contribute to tare.

Calculate payload capacity by subtracting tare from applicable mass limits. Consider both gross vehicle mass and individual axle group limits. The vehicle might be under GVM but still breach axle limits due to load distribution.

Verify actual mass using weighbridge facilities or onboard weighing systems. Portable weighing equipment provides reasonable estimates but permanent weighbridges offer most accuracy.

Load Restraint Best Practices

Proper load restraint prevents cargo movement that could destabilize the vehicle or create road hazards. Load Restraint Guide provides authoritative guidance on restraint methods.

Select restraint methods appropriate for your cargo type, vehicle configuration, and journey characteristics. Different loads require different approaches. Bulk materials, palletized goods, and specialized cargo each present unique restraint challenges.

Use sufficient restraint equipment in good condition. Worn chains, damaged straps, or insufficient tie-down points compromise restraint effectiveness. Inspect restraint equipment regularly and replace degraded items.

Train loading personnel in proper restraint techniques. Knowing what restraint is required means nothing if loading crews don’t implement it correctly. Practical, hands-on training works better than classroom theory.

Permit Management for Oversize and Overmass Loads

When standard limits don’t accommodate your loads, permits allow compliant operation outside normal parameters. Permits specify conditions that must be followed exactly.

Apply for permits before journeys requiring them. Last-minute applications create delays and may not receive approval in time. Build permit lead times into your operational planning.

Understand permit conditions thoroughly. Route restrictions, time-of-day limits, escort requirements, and notification obligations aren’t optional. Breaching permit conditions invalidates the permit.

Maintain permit documentation accessible to drivers. They need immediate access to prove authorization if questioned during enforcement activities.

Building a Safety Management System for HVNL Compliance

A Safety Management System provides the documented framework for managing HVNL compliance systematically. It transforms compliance from individual transactions to a managed business process.

Your SMS should address policy and commitment, planning and implementation, monitoring and measurement, and management review and improvement. These elements create a complete management cycle.

Developing Policies and Procedures

Write policies that clearly state your organization’s commitment to HVNL compliance. Make them specific enough to guide decisions but flexible enough to accommodate operational realities.

Develop procedures for each compliance area. Document how you manage fatigue, maintain vehicles, control mass and loading, verify speed compliance, and oversee contractors. Procedures should be detailed enough that new employees can follow them.

Make documents accessible to everyone who needs them. Procedures locked in filing cabinets don’t influence behavior. Use your intranet, mobile apps, or other tools to ensure ready access.

Review and update documents regularly. HVNL requirements change, your operations evolve, and you identify better practices. Documents should reflect current requirements and actual practice.

Training and Competency Development

Effective training goes beyond initial induction to ongoing competency development. Different roles require different knowledge and skills.

Drivers need detailed fatigue rules, vehicle inspection skills, and load restraint knowledge. Schedulers need to understand how their decisions affect driver compliance. Loading staff need proper restraint training. Executives need strategic understanding of CoR obligations and due diligence requirements.

Use varied training methods. Classroom sessions work for knowledge transfer. Practical demonstrations build skills. Regular refreshers maintain competency over time. Toolbox talks address specific issues as they arise.

Document training completion and assess competency. Records prove your investment in capability development. Assessments verify that training translates to actual competence.

Monitoring, Auditing, and Continuous Improvement

Monitoring provides ongoing visibility of compliance status. Auditing verifies that your systems work as intended. Together they drive continuous improvement.

Implement daily, weekly, and monthly monitoring appropriate to different risks. High-risk areas require frequent attention. Lower-risk areas can use less intensive monitoring.

Conduct internal audits periodically. Review different compliance areas on a rotating schedule so everything receives audit attention annually. Use audit findings to improve systems rather than simply identifying problems.

Analyze trends in your monitoring and audit data. Declining compliance rates, increasing incidents, or recurring issues indicate systemic problems requiring management attention.

Implement corrective actions when issues surface. Document what you’ll do, who’s responsible, and target completion dates. Follow through to verify effectiveness.

Working with the National Heavy Vehicle Regulator

NHVR administers HVNL compliance and enforcement. Understanding their role and approach helps you engage constructively when compliance issues arise.

NHVR takes a graduated enforcement approach. They provide education and warnings for less serious breaches while pursuing stronger action for serious or repeated non-compliance. Cooperation generally leads to better outcomes than adversarial approaches.

Responding to Compliance Investigations

If NHVR investigates a potential breach, respond professionally and cooperatively. Refusing access or withholding information typically worsens outcomes.

Understand what information NHVR can require. They have powers to inspect vehicles, examine records, and interview personnel. Know your obligations while protecting any legitimate privileges.

Seek professional advice for serious matters. HVNL breaches can carry significant penalties, and responses to investigations create records that may be used in proceedings. Legal or specialized compliance advice helps navigate complex situations.

Use investigations as learning opportunities. Even when breaches occurred, demonstrating that you’ve identified root causes and implemented corrections shows responsible management.

Accessing NHVR Guidance and Support

NHVR provides extensive guidance materials, fact sheets, and decision-making tools. Use these resources to understand requirements and improve your compliance systems.

The NHVR website offers information on specific compliance topics, permit applications, approved EWD providers, and regulatory updates. Regularly check for new materials relevant to your operations.

Attend NHVR industry forums and workshops when available. These sessions provide opportunities to hear directly from regulators and ask questions about specific situations.

Consider engaging with industry associations that work with NHVR on policy development. Collective industry input helps shape practical regulatory approaches.

Technology Solutions Supporting HVNL Compliance

Technology increasingly supports HVNL compliance through automation, data capture, and analysis capabilities that manual systems can’t match. Strategic technology adoption improves compliance while reducing administrative burden.

Consider where technology adds genuine value rather than pursuing systems for their own sake. The best technology integrates with your operations and provides actionable information.

Telematics and Fleet Management Systems

Telematics systems capture vehicle location, movement, and performance data. This information supports fatigue monitoring, speed compliance, and vehicle maintenance.

Modern telematics integrate with EWD systems to automatically record driving time. This reduces driver workload and improves accuracy compared to manual recording.

Use telematics data to identify operational risks. Patterns of harsh braking might indicate driver behavior issues or schedule pressure. Excessive idling might reveal inefficient loading processes.

Implement alerts for critical compliance events. Real-time notification when drivers approach work hour limits or vehicles exceed speed restrictions enables immediate intervention.

Maintenance Management Software

Maintenance management systems schedule preventive maintenance, track service history, and manage defect reporting. They ensure vehicles receive appropriate attention on time.

Link maintenance scheduling to actual vehicle usage rather than calendar dates alone. Vehicles operating in harsh conditions may require more frequent servicing than those in standard operations.

Use the system to generate compliance reports showing maintenance currency. When auditors ask about vehicle standards compliance, comprehensive maintenance records demonstrate your systematic approach.

Compliance Management Platforms

Dedicated compliance management platforms consolidate multiple compliance functions in integrated systems. They may include document management, training records, risk assessment tools, and audit management.

Systems like CoRGuard provide specialized HVNL compliance functionality including Chain of Responsibility mapping, obligation tracking, and compliance verification. Purpose-built platforms understand heavy vehicle compliance requirements better than generic business systems.

Evaluate whether integrated platforms or best-of-breed point solutions suit your needs. Integrated platforms offer convenience and data sharing. Specialized point solutions might provide superior functionality in specific areas.

Whatever technology you adopt, ensure people receive proper training. Sophisticated systems deliver value only when users understand and employ their capabilities effectively.

Common HVNL Compliance Challenges and Solutions

Even well-intentioned operations face compliance challenges. Understanding common problems and proven solutions helps you avoid or address these issues.

Managing Compliance Across Multiple CoR Parties

Supply chains involve numerous parties, each controlling different compliance elements. Coordination challenges create gaps where compliance failures occur.

Establish clear contractual obligations specifying each party’s responsibilities. Don’t rely on assumptions about who manages what. Written agreements create accountability.

Implement communication protocols for compliance-critical information. How do schedulers inform operators about delivery timeframes? How do operators notify consignors about vehicle limitations? Systematic communication prevents problems.

Conduct joint compliance reviews with key supply chain partners. Understanding each other’s constraints and capabilities helps identify practical solutions to shared challenges.

Balancing Operational Demands with Compliance Requirements

Business pressure to meet customer demands sometimes conflicts with compliance requirements. Short-term gains from non-compliance create long-term risks.

Build compliance requirements into customer commitments from the start. When you quote delivery times or accept orders, factor in fatigue rules, mass limits, and other constraints. Unrealistic promises force compliance breaches.

Educate customers about regulatory requirements affecting service delivery. Many don’t understand how HVNL rules impact transport operations. Patient explanation often gains acceptance of necessary timeframes.

Develop contingency plans for unexpected delays. When compliance requirements extend timeframes, how will you manage customer expectations and operational impacts? Planning reduces pressure for non-compliant shortcuts.

Addressing Resource Constraints in Smaller Operations

Smaller operators and businesses face HVNL compliance requirements without large compliance teams or sophisticated systems. Resource constraints don’t eliminate obligations but require practical approaches.

Focus resources on highest-risk compliance areas first. If fatigue breaches represent your greatest exposure, prioritize that area before less critical concerns. Proportionate attention matches resource limitations.

Use industry associations and shared resources. Many associations provide members with compliance tools, templates, and advice. Leverage collective resources rather than building everything independently.

Consider outsourcing specialized compliance functions. Professional compliance auditors, consultants, or training providers bring expertise and systems that small operations can’t justify developing internally.

Implement simple but systematic processes. Compliance doesn’t require complex systems, but it does require consistent application. Well-designed checklists and straightforward procedures work effectively.

Key Questions About HVNL Compliance

How do you ensure employees’ compliance with legislation and regulation?

Ensure employees comply with legislation through clear policy implementation, role-specific training, and continuous monitoring. Map legal obligations to specific business processes and assign control owners. Conduct regular transaction reviews, attestations, and exception reporting to verify employees follow requirements in daily operations.

What are the 5 steps to compliance?

A practical five-step compliance approach includes identifying obligations and risks, assessing their significance, designing appropriate controls, implementing those controls across operations, and monitoring effectiveness while continuously improving. This cycle reflects how regulators expect effective compliance programs to operate.

What is the best way to ensure compliance?

Build risk-based compliance monitoring that identifies obligations, prioritizes them by risk level, assigns control owners, and conducts ongoing verification. Integrate this with structured risk management that analyzes, evaluates, and treats risks to ensure controls remain effective as regulations and operations evolve.

Taking Action on HVNL Compliance

HVNL compliance requires systematic attention across multiple operational areas. The regulatory framework extends responsibility beyond drivers to everyone influencing transport activities through Chain of Responsibility obligations.

Effective compliance starts with understanding your specific obligations based on the control you exercise. From there, implement documented systems addressing fatigue management, vehicle standards, mass and dimension limits, speed, and loading. Monitor your compliance status continuously rather than reacting to problems after they occur.

Your next step depends on where you currently stand. If you’re building compliance systems from scratch, start with the HVNL compliance fundamentals before diving into detailed requirements. If you’re strengthening existing systems, conduct a thorough gap analysis using the compliance checklist to identify specific areas requiring attention.

For operations dealing with Chain of Responsibility complexities across multiple parties, review your CoR best practices to ensure all parties understand their obligations and implement appropriate controls.

Focus on building sustainable systems rather than quick fixes. HVNL compliance isn’t a one-time project but an ongoing management responsibility. The businesses that succeed integrate compliance into their operational DNA rather than treating it as a separate administrative task.

Twenty-five years working across supply chain operations has reinforced one truth: compliance systems work when they’re built by people who understand both the regulations and the operational realities. Theory without practical application creates paper systems that fail under pressure. Operations without regulatory grounding create risk exposure.

Build systems that work for your specific circumstances. Take the frameworks and approaches outlined here and adapt them to your operational context, resource constraints, and risk profile. Effective HVNL compliance reflects your commitment to safety and professional operations.