Safety management systems work when organisations treat them as operational tools, not paperwork exercises. In 2022, private industry employers in the U.S. reported 2.8 million nonfatal workplace injuries and illnesses, an increase of 7.5% from 2021. These numbers show what happens when safety systems fail to connect with daily operations.

A functional SMS reduces risk through systematic approaches. It identifies hazards before incidents occur. It creates accountability structures that actually work.

This guide draws on 25 years of supply chain experience to explain what makes safety management systems effective. You’ll learn the four core components organisations need. You’ll see how to implement risk management processes that fit operational reality. You’ll understand which standards matter and why.

The difference between compliant organisations and safe organisations lies in execution. Strong SMS frameworks integrate into operations rather than sitting in binders. They measure leading indicators, not just incident reports. They engage workers who actually perform the work.

Understanding What Makes a Safety Management System Work

A safety management system is a structured framework that identifies hazards, assesses risks, and implements controls. The definition matters less than the function.

SMS frameworks organise safety activities into repeatable processes. They document procedures so knowledge transfers across teams. They create feedback loops that drive continuous improvement.

Modern SMS implementations follow systematic approaches. These approaches share common characteristics regardless of industry.

| SMS Characteristic | Operational Function | Business Outcome |

|---|---|---|

| Proactive Risk Management | Identifies hazards before incidents occur | Reduced injury rates and operational disruptions |

| Systematic Processes | Standardises safety activities across operations | Consistent application and reduced variability |

| Data-Driven Decisions | Uses performance indicators to guide improvements | Targeted resource allocation and measurable progress |

| Integrated Operations | Embeds safety into daily work activities | Sustained compliance without separate programs |

The systems approach addresses a fundamental problem. Safety risks exist across every operational process. One-off initiatives can’t cover the complexity.

SMS provides structure without rigidity. The framework adapts to different operational contexts while maintaining core principles. Understanding key components of a safety management system helps organisations tailor approaches to their specific risks.

Effective SMS implementation starts with clear safety policy. This policy establishes management commitment and sets safety objectives. Without this foundation, the rest of the system lacks direction.

The Four Core Components Every SMS Needs

Now that you understand what SMS frameworks do, examine the structure that makes them work. Four components form the foundation of effective safety management systems.

Safety Policy: Establishing Direction and Commitment

Safety policy defines organisational commitment to safety management. It states objectives that guide all safety activities. The policy comes from senior leadership and applies throughout operations.

Effective safety policies identify the accountable executive. This person holds ultimate responsibility for SMS implementation. They control resources and make strategic decisions about safety priorities.

The policy document should state clear safety objectives. These objectives provide measurable targets for safety performance. They connect to business operations rather than existing as separate goals.

Management commitment extends beyond signing documents. Leaders demonstrate commitment through resource allocation, performance expectations, and visible participation in safety activities.

Safety Risk Management: The Core Function

Safety risk management processes identify hazards systematically. Teams analyse potential consequences and implement appropriate controls. This component drives the proactive nature of SMS.

Hazard identification uses multiple methods. These include workplace inspections, incident analysis, worker reports, and operational reviews. Regular identification activities catch risks before they cause harm.

Risk assessment evaluates each identified hazard. The assessment considers likelihood and severity of potential consequences. This analysis prioritises which risks need immediate attention.

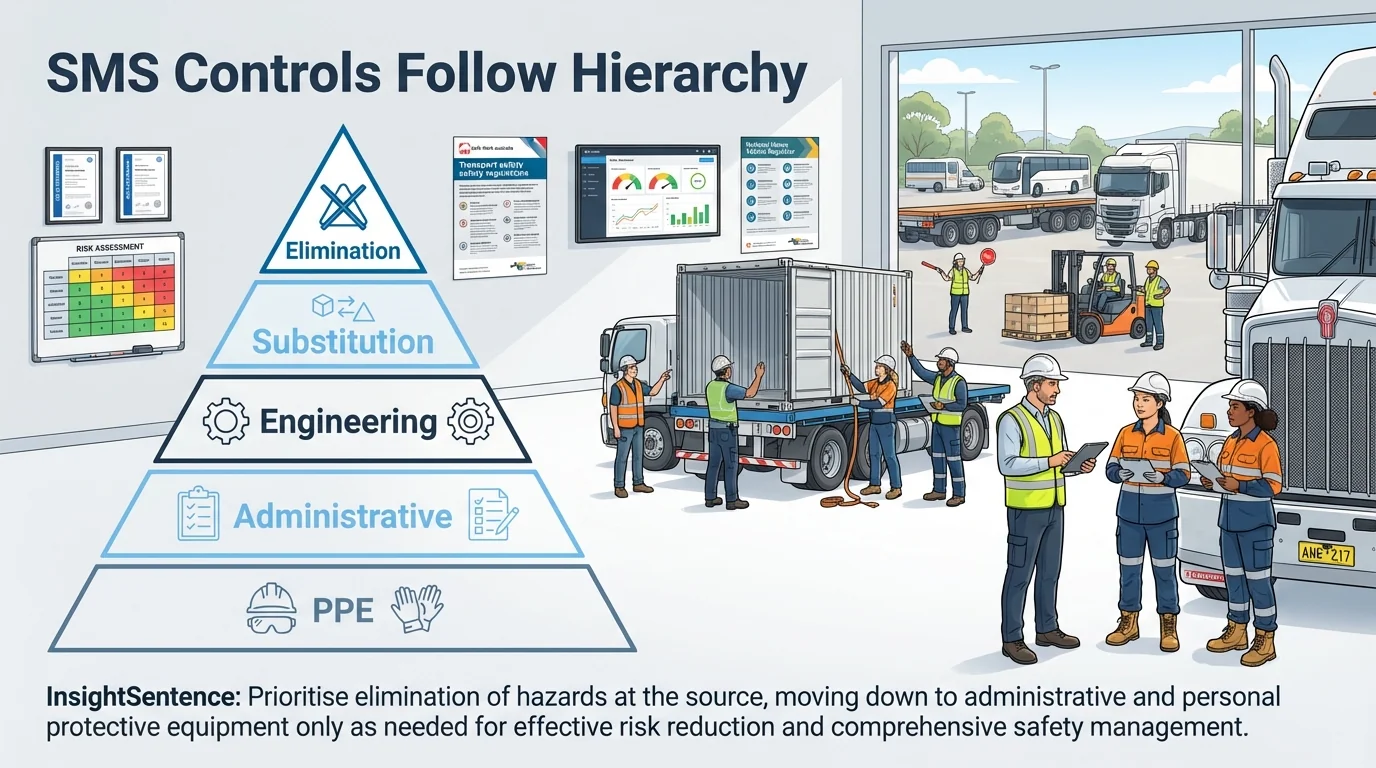

Risk controls follow a hierarchy. Engineering solutions that eliminate hazards work best. Administrative controls and training come next. Personal protective equipment serves as the last line of defense when other controls can’t fully mitigate risk.

Safety Assurance: Monitoring and Verification

Safety assurance confirms that SMS components function as designed. This verification happens through audits, reviews, and performance monitoring. The process identifies gaps between planned and actual performance.

Safety performance indicators measure system effectiveness. Leading indicators track proactive activities like inspections completed and hazards reported. Lagging indicators measure outcomes like injury rates and incident frequency.

Internal audits examine SMS compliance systematically. Auditors review documentation, observe activities, and interview workers. They identify non-conformances and opportunities for improvement.

Management reviews occur at regular intervals. Senior leaders examine audit findings, performance trends, and change requirements. These reviews drive strategic decisions about safety management.

Safety Promotion: Building Culture and Capability

Safety promotion develops the culture and competence needed for SMS success. Training builds worker capability to perform safety functions. Communication reinforces safety priorities and shares lessons learned.

Safety culture reflects how organisations actually value safety. Strong safety culture means workers speak up about hazards. They participate in safety activities because they understand the benefit, not just because procedures require it.

Training programs verify competence, not just attendance. Workers demonstrate they can apply safety procedures in actual work contexts. Implementing a safety management system requires sustained training investment.

Safety communication flows in multiple directions. Leadership communicates expectations and decisions. Workers report hazards and suggest improvements. The communication creates shared understanding of safety priorities.

Critical SMS Elements That Drive Results

With core components established, examine specific elements that make each component effective. Twelve elements appear consistently across successful SMS implementations.

These elements translate broad components into operational activities. They specify what organisations actually do to manage safety risks.

Documentation and Record Management

Documentation captures safety knowledge and creates accountability. Procedures describe how to perform safety activities. Records prove activities occurred as planned.

Effective documentation balances detail with usability. Procedures need enough specificity to ensure consistent application. But excessive detail makes documents hard to use and maintain.

Record management systems track safety activities systematically. These systems store inspection reports, training records, incident investigations, and audit findings. Good records support trend analysis and demonstrate due diligence.

Emergency Preparedness and Response

Emergency response procedures address scenarios that exceed normal operational controls. Plans identify potential emergencies, assign response roles, and establish communication protocols.

Regular drills test emergency procedures under realistic conditions. These exercises reveal gaps in planning or capability. They build worker confidence in emergency response.

Post-emergency reviews examine what worked and what needs improvement. Organisations update procedures based on lessons learned. This continuous improvement extends to emergency management.

Contractor and Vendor Management

Contractor safety integration matters particularly in high-hazard industries. Contractors work under different employment arrangements but face the same operational risks.

Contractor management starts with safety requirements in procurement processes. Contracts specify safety expectations, performance standards, and verification methods.

Pre-work safety inductions orient contractors to site-specific hazards. Ongoing monitoring confirms contractors maintain safety standards. This oversight prevents contractors from becoming weak points in safety management.

Why Organisations Implement Safety Management Systems

Having examined what SMS includes, consider why organisations invest in systematic safety management. Benefits extend beyond regulatory compliance.

The total cost of work injuries in the U.S. was estimated at $167 billion in 2021. These costs include medical expenses, lost productivity, and administrative expenses. Effective SMS reduces these costs through incident prevention.

Fewer incidents mean lower insurance premiums. Insurance providers recognise organisations with strong safety management systems. They adjust premiums to reflect reduced risk exposure.

SMS implementation improves operational efficiency. Hazard identification reveals process inefficiencies. Risk controls often streamline operations while improving safety. The systematic approach eliminates redundant activities.

Strong safety performance enhances business relationships. Clients increasingly require safety management evidence from suppliers and contractors. SMS provides documentation that satisfies these requirements.

Worker engagement improves when organisations demonstrate genuine safety commitment. Employees notice when leaders allocate resources to safety. They respond by participating more actively in safety programs.

Regulatory compliance becomes more manageable under SMS frameworks. The systematic approach addresses legal requirements comprehensively. Unlocking the benefits of a safety management system shows how structure simplifies compliance.

Building Effective Safety Risk Management Processes

Now focus on the component that drives SMS effectiveness. Safety risk management processes determine which hazards organisations address and how they allocate resources.

Systematic Hazard Identification Methods

Hazard identification requires multiple information sources. No single method catches every risk.

Workplace inspections examine physical conditions systematically. Inspectors follow checklists that cover known hazard categories. They document findings with photos and precise locations.

Job safety analysis breaks work activities into steps. Analysts identify hazards at each step and develop specific controls. This detailed approach works well for high-risk activities.

Worker reporting systems capture hazards that formal processes miss. Workers encounter risks daily that inspections might not detect. Easy reporting mechanisms encourage participation.

Incident investigation reveals hazards that caused actual harm. Root cause analysis identifies underlying conditions beyond immediate causes. This analysis prevents similar incidents.

Risk Assessment and Prioritisation

Risk assessment evaluates each identified hazard systematically. The assessment considers both likelihood and severity of potential consequences.

Risk matrices provide consistent evaluation frameworks. They classify risks as high, medium, or low based on assessment criteria. This classification drives resource allocation decisions.

Organisations prioritise high risks for immediate action. Medium risks receive scheduled attention. Low risks get documented but may not require immediate controls.

Assessment quality depends on participant knowledge. Involve workers who perform the activities being assessed. They understand operational reality better than distant analysts.

Control Selection and Implementation

Control selection follows the hierarchy of controls. This hierarchy ranks control types by effectiveness.

Elimination removes hazards completely. This provides absolute protection but isn’t always feasible. When possible, elimination offers the best risk reduction.

Substitution replaces hazardous materials or processes with safer alternatives. This reduces risk without eliminating the function. Engineering controls use physical modifications to reduce risk exposure.

Administrative controls change how people work. These include procedures, training, and work scheduling. They depend on consistent human performance.

Personal protective equipment provides the last defense layer. PPE protects when other controls can’t fully eliminate risk. It requires proper selection, maintenance, and use.

SMS Implementation: From Planning to Operation

Understanding SMS components differs from implementing them. Now examine how organisations move from planning to operational reality.

Gap Analysis and Readiness Assessment

Implementation starts with understanding current state. Gap analysis compares existing safety activities against SMS requirements.

The assessment identifies what already exists. Many organisations have safety activities but lack systematic structure. SMS implementation organises existing activities rather than starting from zero.

Gap analysis reveals what needs development. This includes missing procedures, inadequate training, or weak performance monitoring. The findings create implementation priorities.

Readiness assessment examines organisational capacity. Consider available resources, leadership support, and change management capability. Realistic assessment prevents implementation failures.

Phased Implementation Approach

Phased implementation spreads workload and manages change. Attempting full implementation immediately overwhelms organisations.

Phase one typically establishes safety policy and leadership commitment. This foundation supports subsequent phases. It signals that implementation has genuine management backing.

Phase two develops core documentation and procedures. Teams create standard processes for hazard identification, risk assessment, and incident investigation. These processes enable systematic safety management.

Phase three implements safety assurance mechanisms. Organisations establish performance monitoring, audit programs, and management review processes. These mechanisms verify that planned systems work.

Phase four focuses on continuous improvement and culture development. By this phase, basic systems function. Attention shifts to optimisation and engagement.

Training and Communication Planning

Training requirements vary by role. Senior leaders need strategic SMS understanding. Safety managers require detailed technical knowledge. Workers need role-specific competencies.

Training programs specify learning objectives clearly. They define what participants must demonstrate, not just what content covers. Verification confirms competence through observation or assessment.

Communication planning supports implementation throughout phases. Regular updates explain progress, address concerns, and celebrate achievements. Communication maintains momentum during lengthy implementations.

Creating Strong Safety Culture Through SMS

With implementation underway, focus shifts to the cultural elements that determine long-term success. Procedures and documentation provide structure, but culture determines whether people use them.

Safety culture reflects actual priorities versus stated priorities. Workers judge what organisations value by observing decisions, not reading policy documents. Meta-analytic research on safety climate has found that management safety commitment is associated with lower injury rates.

Leadership behaviour shapes culture powerfully. When leaders visibly participate in safety activities, workers notice. When production pressures override safety concerns, workers notice that too.

Worker participation builds ownership of safety outcomes. Involving workers in hazard identification and control selection increases buy-in. They provide practical insights that improve control effectiveness.

Recognition programs reinforce desired behaviours. Acknowledge workers who report hazards or suggest improvements. Recognition signals that organisations value proactive safety engagement.

Just culture approaches balance accountability with learning. They distinguish between human error, at-risk behaviour, and reckless behaviour. This distinction allows organisations to learn from mistakes without punishing honest errors.

Safety communication happens continuously, not just during incidents. Regular discussions about safety performance, emerging risks, and improvement opportunities keep safety visible. They prevent safety from becoming an afterthought.

Standards and Frameworks That Guide SMS Development

Now examine the standards and frameworks that inform SMS development. These provide structured approaches based on accumulated industry experience.

ISO 45001: International Occupational Health and Safety Standard

ISO 45001 provides an internationally recognised framework for occupational health and safety management systems. The standard applies across industries and organisation sizes.

ISO 45001 uses the Plan-Do-Check-Act methodology. This continuous improvement cycle drives ongoing SMS enhancement. Organisations plan safety activities, implement them, check results, and act on findings.

The standard emphasises integration into business processes. Safety management shouldn’t exist separately from operational management. Integrated approaches ensure safety receives attention in all business decisions.

ISO 45001 certification demonstrates SMS conformance to external parties. Certification requires third-party audit. Many organisations pursue certification to satisfy client requirements or competitive positioning.

ICAO SMS Framework for Aviation

The International Civil Aviation Organization developed SMS frameworks specifically for aviation operations. ICAO SMS standards now apply globally in aviation.

ICAO’s four-component structure aligns with the framework discussed earlier. Safety policy, safety risk management, safety assurance, and safety promotion form the core components.

Aviation SMS includes specific requirements for safety reporting systems. These systems enable confidential hazard reporting. They support safety culture by protecting reporters from punitive responses.

State safety programs coordinate SMS implementation across aviation sectors. Regulators establish minimum standards while allowing flexibility in implementation approaches.

OSHA Guidelines and Regulatory Requirements

The Occupational Safety and Health Administration provides recommended practices for safety and health programs. While not mandating SMS specifically, OSHA guidelines align with SMS principles.

OSHA emphasises management leadership, worker participation, and systematic hazard identification. These elements appear in all effective SMS implementations.

Some jurisdictions have specific SMS regulatory requirements. These requirements vary by industry and location. Organisations must understand applicable regulations in their operating contexts.

Measuring SMS Performance and Driving Continuous Improvement

Finally, examine how organisations measure SMS effectiveness and drive ongoing improvement. Performance measurement distinguishes functional systems from paperwork exercises.

Safety performance indicators fall into two categories. Leading indicators measure proactive safety activities. Lagging indicators measure safety outcomes.

Leading indicators include inspections completed, hazards reported, and training delivered. These metrics predict future performance. They provide early warning when safety activities decline.

Lagging indicators measure incidents, injuries, and near-misses. These outcome measures show whether SMS effectively controls risks. However, they only reveal problems after incidents occur.

Balanced measurement uses both indicator types. Leading indicators guide day-to-day activities. Lagging indicators validate whether activities achieve intended results.

Data analysis identifies trends and patterns. Look for correlations between activities and outcomes. Analysis reveals which SMS elements need strengthening.

Management reviews examine performance data systematically. Reviews occur at defined intervals, typically quarterly or annually. They drive strategic decisions about SMS improvements.

Continuous improvement processes turn findings into actions. Organisations identify improvement opportunities, implement changes, and monitor results. The Plan-Do-Check-Act cycle ensures SMS evolves with changing risks.

| Performance Area | Example Indicators | Measurement Frequency |

|---|---|---|

| Hazard Identification | Hazards reported per month, inspection completion rates | Monthly |

| Training Effectiveness | Competency verification rates, training hours per worker | Quarterly |

| Incident Performance | Recordable injury rate, lost time injury frequency | Monthly |

| Audit Compliance | Audit findings closed on time, repeat findings | Quarterly |

Technology supports performance monitoring. Safety management system software tracks activities, manages documentation, and generates reports. Digital systems improve data quality and accessibility.

Regular safety meetings review performance data with workers. These discussions make data meaningful to people doing the work. They identify practical improvement opportunities that management might miss.

Making SMS Work in Operational Reality

Safety management systems deliver results when organisations treat them as operational tools. The systematic approach identifies hazards proactively, implements effective controls, and drives continuous improvement.

Success requires genuine leadership commitment. Resources must follow policy statements. Safety priorities need protection during operational pressures.

Worker participation matters throughout SMS lifecycles. Those performing the work understand risks and control effectiveness better than anyone. Their engagement builds culture and improves outcomes.

Start with gap analysis to understand current capabilities. Implement changes in manageable phases. Verify that systems work through regular audits and performance monitoring.

Measure both activities and outcomes. Use data to guide improvement decisions. Review performance regularly at management level.

Safety management systems aren’t destinations. They’re continuous improvement frameworks that evolve with changing operations and emerging risks. Organisations that maintain this perspective achieve sustained safety performance.

The choice sits with leadership. Invest in systematic safety management or accept preventable incidents. The data shows which approach costs less and protects better. Top safety management system practices demonstrate what works across diverse operational contexts.