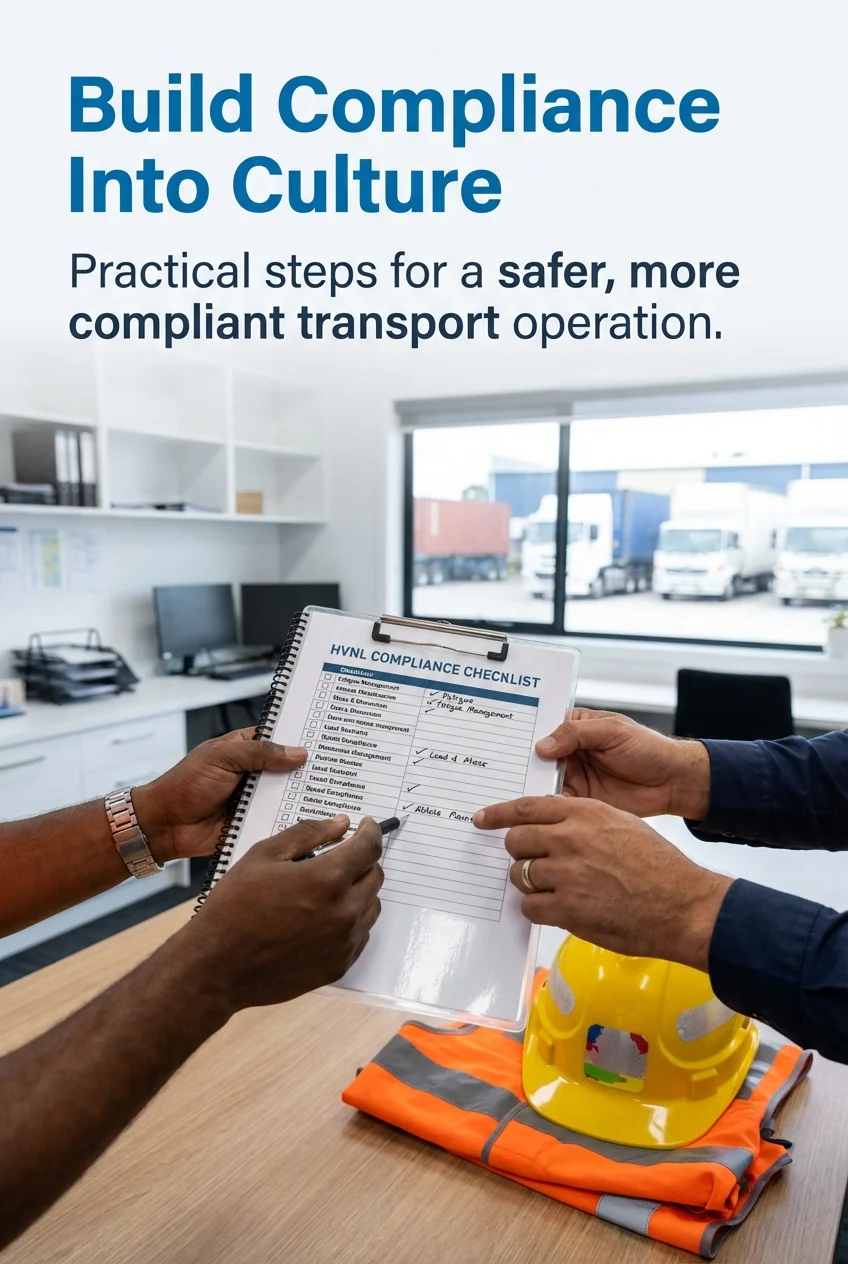

Transport operators working under Australia’s Heavy Vehicle National Law need more than good intentions. They need systematic verification across every compliance obligation. The HVNL establishes a comprehensive regulatory framework for heavy vehicles in Australia, covering vehicle standards, fatigue management, mass and dimension limits, speed compliance, and Chain of Responsibility obligations. This compliance checklist provides transport operators with the verification points necessary to meet NHVR requirements, manage regulatory risk, and maintain operational safety across their entire heavy vehicle operation.

Compliance extends beyond drivers and vehicles. Transport operators must understand compliance extends beyond individual drivers to encompass all parties through Chain of Responsibility obligations, creating accountability for consignors, consignees, schedulers, loaders, and other parties in the supply chain.

This checklist addresses the operational realities of maintaining compliance. Transport operators face inspection by NHVR enforcement officers, potential breaches carrying significant penalties, and the practical challenge of managing documentation across multiple compliance areas. The following sections break down HVNL requirements into verifiable checkpoints organized by compliance category, providing clear reference points for internal audits and operational management.

Understanding HVNL Compliance Requirements

The Heavy Vehicle National Law creates the legal foundation for all heavy vehicle operations in Australia. Transport operators must recognize that HVNL compliance operates as an integrated system rather than isolated requirements.

The National Heavy Vehicle Regulator administers the HVNL and provides guidance on interpretation and application. Operators should reference NHVR resources for current regulatory standards and compliance expectations. The amended HVNL is expected to commence in mid-2026, requiring operators to monitor regulatory changes and update systems accordingly.

Primary Duty Requirements

The HVNL establishes a primary duty for all parties in the Chain of Responsibility. This duty requires each party to ensure their actions or inactions do not cause or contribute to breaches of the Heavy Vehicle National Law.

Transport operators must demonstrate due diligence in meeting this primary duty. This includes implementing systems to identify risks, eliminating or minimizing those risks, monitoring effectiveness of control measures, and maintaining records that demonstrate compliance efforts.

Regulatory Framework Structure

The HVNL covers six key compliance areas that operators must address systematically. Each area carries specific obligations, documentation requirements, and enforcement provisions.

| Compliance Area | Core Requirements | Key Obligations |

|---|---|---|

| Chain of Responsibility | Primary duty, due diligence, risk management systems | Implement safety systems, monitor compliance, maintain audit trail |

| fatigue management | Work and rest hours, work diary records, scheduling practices | Monitor driver hours, verify work diary accuracy, prevent fatigue-related breaches |

| Vehicle Standards | Roadworthy condition, maintenance schedules, defect management | Conduct regular inspections, maintain service records, address defects promptly |

| Mass and Dimension | Weight limits, dimension restrictions, load distribution | Verify load weights, ensure proper loading, obtain necessary permits |

| Load Restraint | Securing requirements, restraint standards, load stability | Apply appropriate restraints, inspect load security, follow Load Restraint Guide |

| Speed Compliance | Speed limit adherence, monitoring systems, driver management | Track vehicle speeds, address violations, implement speed management systems |

Understanding how these areas interconnect helps operators build integrated compliance systems. For example, fatigue management connects to scheduling, which impacts speed compliance and loading practices.

Chain of Responsibility Compliance Checklist

Chain of Responsibility obligations apply to all parties involved in transport operations. The Chain of Responsibility framework extends accountability beyond drivers to include anyone whose actions influence heavy vehicle safety.

Transport operators must identify all parties in their CoR network. This typically includes the operator, drivers, schedulers, consignors, consignees, loaders, and anyone else who exercises control or influence over transport activities.

CoR Party Identification and Documentation

- Document all parties with influence over transport operations

- Define roles and responsibilities for each CoR party

- Establish communication protocols between parties

- Maintain current contact information for all parties

- Review party list quarterly for accuracy

Primary Duty Implementation

Each party must understand their obligations under HVNL duty holder requirements. Transport operators should verify that systems exist to prevent breaches occurring from their activities.

- Conduct risk assessments for all transport activities

- Document control measures addressing identified risks

- Implement monitoring systems for compliance verification

- Establish incident reporting and investigation procedures

- Review and update risk assessments when operations change

Due Diligence Requirements

Due diligence forms the foundation of CoR compliance. Operators must demonstrate active management of compliance obligations through systematic processes.

- Acquire knowledge of HVNL requirements applicable to operations

- Understand operational activities and associated risks

- Verify resources are adequate for safe operations

- Implement processes ensuring compliance with HVNL

- Monitor effectiveness of compliance systems

- Maintain records demonstrating due diligence efforts

Contractual Arrangements Review

Contracts between CoR parties should support compliance rather than create pressure for unsafe practices. Review all contracts to ensure they do not encourage or require HVNL breaches.

- Review delivery timeframes for reasonableness

- Verify payment terms do not incentivize unsafe practices

- Include compliance requirements in contracts

- Establish processes for managing delivery delays

- Document contract variations affecting compliance obligations

Fatigue Management Compliance Points

Fatigue management represents one of the most critical compliance areas under the HVNL. Operators must manage driver work and rest hours, maintain accurate records, and implement systems preventing fatigue-related breaches.

The HVNL establishes different work and rest requirements depending on whether operations fall under Standard Hours, Basic Fatigue Management, or Advanced Fatigue Management. Transport operators must identify which fatigue management option applies to their operations and ensure compliance with the corresponding requirements.

Work and Rest Hours Verification

Operators must verify drivers comply with applicable work and rest requirements. This requires systematic monitoring of driver hours and proactive management of schedules.

- Confirm which fatigue management option applies to each driver

- Monitor daily work hours against applicable limits

- Verify rest breaks meet minimum duration requirements

- Check cumulative work hours over rolling periods

- Review upcoming schedules for potential breaches

- Address scheduling issues before drivers commence work

Work Diary Requirements

Accurate work diary records provide essential evidence of compliance with fatigue management requirements. Operators must ensure drivers maintain proper records and verify accuracy regularly.

- Verify all drivers maintain current work diaries

- Check work diary entries match actual activities

- Review work diaries weekly for accuracy and completeness

- Address missing or incorrect entries immediately

- Retain work diary records for required retention period

- Consider implementing Electronic Work Diary systems for improved accuracy

Scheduling Practices Review

Schedulers play a direct role in fatigue management compliance. Scheduling practices must account for work and rest requirements and provide realistic timeframes for task completion.

- Review scheduling processes for compliance considerations

- Verify schedules allow adequate rest breaks

- Check delivery timeframes permit compliance with speed limits

- Consider traffic conditions and route characteristics in scheduling

- Establish procedures for managing schedule changes

- Document scheduling decisions affecting fatigue compliance

Fatigue Management System Verification

Operators using Basic Fatigue Management or Advanced Fatigue Management must maintain accreditation requirements. This includes regular system reviews and continuous improvement processes.

- Conduct internal audits of fatigue management systems

- Review fatigue risk assessments annually

- Update fatigue management procedures as operations change

- Verify driver training remains current

- Maintain accreditation documentation

- Address non-conformances identified in audits

Vehicle Standards and Maintenance Checklist

Vehicles must meet roadworthy standards at all times under the HVNL. Transport operators carry responsibility for vehicle condition regardless of ownership arrangements. This creates obligations for systematic maintenance and inspection.

Vehicle standards cover everything from brake performance to lighting systems. The National Heavy Vehicle Inspection Manual provides detailed criteria for assessing vehicle condition and identifying defects.

Pre-Trip Inspection Requirements

Drivers must conduct pre-trip inspections before operating heavy vehicles. Operators should implement systems ensuring these inspections occur and defects receive appropriate attention.

- Verify drivers complete pre-trip inspections

- Review inspection reports for identified defects

- Establish defect reporting procedures

- Classify defects by severity level

- Confirm major defects prevent vehicle use

- Track defect rectification to completion

Scheduled Maintenance Programs

Proactive maintenance prevents vehicle defects and ensures ongoing compliance with vehicle standards. Operators must establish and follow systematic maintenance schedules.

- Develop maintenance schedules based on manufacturer recommendations

- Track service intervals for each vehicle

- Conduct periodic safety inspections

- Maintain service records documenting work performed

- Address items identified in service reports

- Review maintenance program effectiveness annually

Defect Management Processes

Defects identified through inspections or driver reports require systematic management. The HVNL prohibits using vehicles with major defects and requires operators to maintain defect records.

- Establish clear defect classification criteria

- Remove vehicles with major defects from service immediately

- Track all defects until rectification

- Verify repairs meet required standards

- Maintain defect records for audit purposes

- Analyze defect patterns to identify systemic issues

Vehicle Modification Documentation

Modifications to heavy vehicles may affect compliance with vehicle standards. Operators must ensure modifications receive proper approval and documentation.

- Verify modifications comply with relevant standards

- Obtain engineering approvals where required

- Update vehicle specifications after modifications

- Maintain modification records with vehicle documentation

- Consider modification impacts on other compliance areas

Mass, Dimension, and Loading Requirements

Heavy vehicles must comply with mass limits, dimension restrictions, and load distribution requirements. These obligations apply to multiple CoR parties including operators, consignors, and loaders.

Mass and dimension breaches carry significant penalties and create safety risks. Operators must implement verification systems preventing overloading and ensuring dimensional compliance.

Mass Limit Verification

Transport operators must verify loads remain within allowable mass limits. This requires accurate weighing systems and proper load documentation.

- Weigh vehicles or verify consignor weight documentation

- Check total mass against vehicle registration limits

- Verify axle group masses meet requirements

- Ensure load distribution maintains compliance

- Obtain Higher Mass Limits permits where required

- Maintain weighing records for audit verification

Dimension Compliance Checks

Vehicle and load dimensions must remain within allowable limits. Operators should verify dimensional compliance before vehicles enter service.

- Confirm vehicle dimensions meet standard requirements

- Verify load dimensions including overhang

- Check overall height including any load projection

- Measure width for loads extending beyond vehicle body

- Obtain dimension permits for non-standard loads

- Review route for dimension restrictions

Loading Procedures and Documentation

Proper loading procedures ensure mass and dimension compliance. Loaders must understand their CoR obligations and follow systematic loading practices.

- Provide loading instructions to all loading personnel

- Verify loading procedures address weight distribution

- Document load weights and dimensions

- Communicate load characteristics to drivers

- Review loading practices for compliance risks

- Train loading personnel on HVNL requirements

Access and Permit Management

Vehicles exceeding standard mass or dimension limits require appropriate permits. Operators must obtain necessary permits and comply with permit conditions.

- Identify when permits are required

- Apply for permits before operating

- Verify permit conditions are understood

- Ensure drivers carry permits during operations

- Comply with route restrictions and time limitations

- Maintain permit records

Load Restraint Compliance Verification

Loads must be properly restrained to prevent movement during transport. The Load Restraint Guide provides performance standards and approved restraint methods for various load types.

Load restraint responsibilities extend across multiple CoR parties. Loaders must apply appropriate restraints, drivers must inspect restraint before departure, and operators must ensure parties understand restraint requirements.

Load Restraint System Selection

Selecting appropriate restraint systems requires understanding load characteristics and applying suitable restraint methods. The Load Restraint Guide details various restraint approaches based on load type.

- Assess load characteristics including weight and stability

- Select restraint method suitable for load type

- Verify restraint equipment meets required standards

- Calculate restraint capacity requirements

- Apply restraint methods according to Load Restraint Guide

- Document restraint approach used

Pre-Departure Inspection Requirements

Drivers must inspect load restraint before departing and at regular intervals during transit. These inspections verify restraint remains effective throughout the journey.

- Conduct visual inspection of all restraint equipment

- Check restraint tension and adjustment

- Verify load has not shifted during loading

- Inspect restraint attachment points

- Establish inspection intervals for longer journeys

- Document restraint inspections

Restraint Equipment Maintenance

Restraint equipment must remain in serviceable condition. Operators should implement inspection and replacement programs for chains, straps, binders, and other restraint equipment.

- Inspect restraint equipment regularly for damage

- Remove damaged equipment from service

- Maintain inventory of serviceable equipment

- Replace worn equipment before failure

- Keep records of equipment inspections

- Store equipment properly when not in use

Speed Compliance Management

Heavy vehicles must comply with applicable speed limits. Speed compliance involves driver behavior, vehicle capabilities, and management systems monitoring compliance.

Operators must implement speed management systems addressing both regulatory requirements and practical safety considerations. This includes driver training, vehicle monitoring, and incident response procedures.

Speed Limit Application and Communication

Drivers must understand which speed limits apply to their operations. Heavy vehicles face different speed restrictions than light vehicles in many jurisdictions.

- Communicate applicable speed limits to drivers

- Provide route information including speed zones

- Brief drivers on location-specific restrictions

- Address speed limiter requirements for certain vehicles

- Update drivers when speed restrictions change

Speed Monitoring Systems

Telematics and speed monitoring systems provide data on vehicle speeds and driver behavior. Operators should utilize available technology to monitor compliance and address issues proactively.

- Implement speed monitoring technology where practical

- Review speed data regularly for compliance

- Establish speed tolerance policies

- Address speed violations through driver coaching

- Document speed management interventions

- Analyze speed data for patterns requiring attention

Driver Behavior Management

Driver behavior directly impacts speed compliance. Operators must address behavior issues through training, coaching, and where necessary, disciplinary processes.

- Provide initial training on speed compliance

- Conduct refresher training periodically

- Address speed violations promptly

- Document coaching and corrective actions

- Escalate persistent violations appropriately

- Recognize positive compliance behavior

Driver Management and Competency Verification

Drivers form the operational front line of HVNL compliance. Transport operators must verify driver competency, provide necessary training, and maintain systems supporting driver compliance.

Driver management extends beyond initial hiring to include ongoing performance monitoring, training updates, and compliance verification. This creates obligations for systematic driver management processes.

Licensing and Qualification Verification

Operators must verify drivers hold appropriate licenses for the vehicles they operate. This requires checking license class, endorsements, and currency.

- Verify driver license class matches vehicle requirements

- Check license expiry dates and renewal status

- Confirm required endorsements are current

- Maintain copies of driver licenses

- Implement license verification schedules

- Address license issues before permitting vehicle operation

Driver Induction and Training

New drivers require induction covering company procedures, vehicle characteristics, and HVNL obligations. Ongoing training addresses regulatory changes and identified competency gaps.

- Conduct structured induction for new drivers

- Cover HVNL compliance obligations in training

- Provide vehicle-specific operating instructions

- Address route characteristics and customer requirements

- Document training completion

- Schedule refresher training periodically

Performance Monitoring and Compliance Tracking

Operators should monitor driver performance across compliance areas. This includes tracking incidents, reviewing compliance data, and addressing performance issues.

- Review driver compliance data regularly

- Track incidents and their causes

- Identify patterns requiring intervention

- Conduct performance reviews with drivers

- Document performance management activities

- Adjust training based on identified needs

Work Diary and Record Keeping Requirements

The HVNL establishes specific record keeping obligations across multiple compliance areas. Transport operators must maintain various records demonstrating compliance with regulatory requirements.

Record keeping serves multiple purposes including compliance verification, audit preparation, and incident investigation. Operators should implement systematic records management covering all HVNL requirements.

Work Diary Record Requirements

Work diaries document driver compliance with fatigue management requirements. Operators must verify work diary accuracy and retain records for the prescribed period.

- Verify all drivers maintain work diaries

- Review work diary accuracy weekly

- Address incomplete or incorrect entries

- Retain work diaries for minimum three years

- Implement storage systems protecting records

- Provide work diary records for NHVR inspection

Vehicle Maintenance and Inspection Records

Maintenance records demonstrate compliance with vehicle standards obligations. These records should document all inspections, services, and repairs.

- Maintain service records for each vehicle

- Document pre-trip and periodic inspections

- Retain defect reports and rectification records

- Keep modification approvals and documentation

- Store vehicle records for required retention period

- Organize records for efficient retrieval

Mass and Loading Documentation

Mass compliance requires documentation of vehicle and load weights. Operators should retain weighbridge dockets, packing lists, and other mass-related records.

- Collect weighbridge tickets for loaded vehicles

- Obtain consignor weight documentation

- Retain load distribution calculations

- Keep permit copies with relevant vehicles

- Document any mass-related incidents

- Store mass records systematically

CoR Documentation and Audit Trail

Chain of Responsibility compliance requires documented evidence of due diligence. Operators must maintain records demonstrating their compliance management activities.

- Document risk assessments and control measures

- Retain training records for all personnel

- Keep contract documents affecting compliance

- Maintain incident investigation reports

- Store compliance monitoring records

- Organize documentation for audit readiness

Safety Management System Implementation

Effective HVNL compliance requires systematic safety management. While not explicitly required under Standard Hours, safety management systems provide the framework for managing compliance obligations across all operational areas.

Operators seeking accreditation under NHVAS or operating under Basic or Advanced Fatigue Management must implement formal safety management systems. However, all operators benefit from systematic approaches to compliance management.

Safety Management System Components

Safety management systems typically include policy statements, risk management processes, training programs, monitoring systems, and continuous improvement mechanisms.

- Develop safety policy addressing HVNL requirements

- Implement risk assessment procedures

- Establish operational procedures for compliance areas

- Create monitoring and reporting systems

- Develop corrective action processes

- Schedule regular system reviews

Internal Audit Programs

Internal audits verify compliance system effectiveness. Operators should conduct regular audits covering all HVNL compliance areas and addressing identified gaps.

- Schedule periodic internal audits

- Cover all HVNL compliance areas systematically

- Document audit findings and non-conformances

- Develop corrective action plans

- Verify corrective actions are implemented

- Review audit results with management

Continuous Improvement Processes

Compliance systems should evolve based on operational experience, regulatory changes, and identified improvements. Operators must review and update systems regularly.

- Review compliance system effectiveness quarterly

- Analyze incidents for systemic causes

- Update procedures based on lessons learned

- Monitor regulatory changes affecting operations

- Implement improvements identified through audits

- Communicate system changes to affected personnel

NHVR Enforcement and Breach Management

The National Heavy Vehicle Regulator conducts enforcement activities including roadside inspections, premises audits, and investigations. Understanding NHVR enforcement helps operators prepare for inspections and manage potential breaches effectively.

NHVR enforcement officers have powers to inspect vehicles, examine documents, and investigate suspected breaches. Operators should train personnel on appropriate responses to enforcement activities and establish procedures for managing enforcement interactions.

Inspection Preparation and Response

Vehicles and documentation should be inspection-ready at all times. This requires maintaining compliance across all areas and ensuring required records are accessible.

- Ensure drivers carry required documentation

- Maintain vehicles in compliant condition

- Train drivers on inspection procedures

- Establish communication protocols for inspections

- Document inspection outcomes

- Address deficiencies identified during inspections

Breach Notification and Response

Breaches identified through inspections or audits require prompt response. Understanding potential penalties and response procedures helps operators manage breach situations effectively.

- Notify management of identified breaches immediately

- Investigate breach circumstances thoroughly

- Document investigation findings

- Implement corrective actions addressing breach causes

- Respond to NHVR inquiries promptly

- Consider legal advice for serious breaches

Infringement Notice Management

Infringement notices represent one enforcement outcome for HVNL breaches. Operators must decide whether to pay infringements or contest them based on circumstances and evidence.

- Review infringement notices carefully

- Verify factual accuracy of alleged breach

- Consider contest options if circumstances warrant

- Meet response timeframes

- Document decisions regarding infringements

- Implement preventive measures for future compliance

Compliance Verification and Audit Preparation

Regular self-assessment helps operators identify compliance gaps before external audits or enforcement activities. Systematic verification processes support ongoing compliance and prepare organizations for NHVR audits.

Transport operators should implement compliance verification schedules covering all HVNL requirements. This includes reviewing documentation, inspecting vehicles, and assessing system effectiveness.

Documentation Readiness Review

Audit preparation begins with ensuring all required records exist, remain current, and are organized for efficient retrieval.

- Verify all required records are maintained

- Check record completeness and accuracy

- Organize documentation systematically

- Address documentation gaps identified

- Update outdated procedures and forms

- Test record retrieval processes

Operational Compliance Assessment

Beyond documentation, operators must verify that actual practices align with procedures and meet HVNL requirements. This involves observing operations and interviewing personnel.

- Observe loading and departure procedures

- Review driver practices against requirements

- Verify maintenance activities meet standards

- Check communication between CoR parties

- Assess whether procedures reflect actual practice

- Identify gaps between documentation and operations

Continuous Monitoring Systems

Effective compliance requires ongoing monitoring rather than periodic checks. Operators should implement systems providing regular compliance data across key areas.

- Establish key performance indicators for compliance areas

- Implement automated monitoring where practical

- Review compliance data weekly

- Trend performance over time

- Address adverse trends proactively

- Report compliance status to management regularly

Implementing Practical HVNL Compliance

This checklist provides verification points across HVNL compliance areas. Transport operators should adapt these items to their specific operations, creating customized checklists reflecting their vehicle types, operating patterns, and organizational structure.

Effective compliance requires more than completing checklists. Operators must build compliance into operational culture, ensuring all personnel understand their obligations and contribute to compliance outcomes.

Regular use of this compliance checklist supports systematic verification of HVNL requirements. Operators should schedule periodic reviews covering all sections, document findings, address identified gaps, and maintain records demonstrating their compliance management efforts. This systematic approach reduces regulatory risk, supports operational safety, and demonstrates the due diligence expected under Chain of Responsibility obligations.