Supply chain risk management software provides organisations with visibility across multiple supplier tiers, real-time monitoring capabilities, and automated risk assessment tools to identify threats before they disrupt operations. These platforms address cybersecurity vulnerabilities, geopolitical instability, financial risks, and compliance requirements through integrated dashboards that map supplier relationships, track regulatory changes, and enable rapid response to emerging threats across your entire supply network.

I’ve spent 25 years working across FMCG supply chains in Australia and the UK. Managing procurement budgets exceeding $20m taught me that risks hide in plain sight.

Your third-tier supplier faces a cyberattack. A regulatory change impacts your overseas vendors. A natural disaster disrupts logistics routes. Without proper visibility and monitoring systems, these events become costly surprises rather than managed risks.

Modern supply chain risk management software transforms how organisations identify and respond to threats. These platforms provide the tools needed to map complex supplier networks, monitor risks continuously, and maintain operational resilience.

What Supply Chain Risk Management Software Actually Does

Supply chain risk management software identifies, assesses, and mitigates threats throughout your supplier network. These platforms create visibility across multiple tiers of suppliers that traditional systems miss.

The software maps relationships between your direct suppliers and their suppliers. This multi-tier visibility reveals hidden dependencies and concentration risks. You discover which components rely on single sources or vulnerable geographic regions.

Real-time monitoring forms the operational core of these systems. Platforms track supplier financial health, cybersecurity incidents, regulatory compliance status, and operational disruptions. Automated alerts notify relevant teams when risk thresholds are exceeded.

Risk assessment methodologies vary by platform. Most systems assign risk scores based on multiple factors including supplier location, financial stability, past performance, and external threat intelligence. These scores prioritise where to focus your mitigation efforts.

Integration capabilities connect risk management software with existing enterprise systems. Data flows between procurement platforms, ERP systems, and supply chain management tools. This integration eliminates manual data entry and ensures consistent information across your organisation.

Core Functionality That Drives Value

Supplier onboarding and due diligence capabilities streamline how new vendors enter your network. Automated questionnaires collect compliance documentation, financial statements, and security certifications. The system flags gaps before contracts are signed.

continuous monitoring replaces periodic audits with ongoing surveillance. The demand for supply chain risk management software is driven by the need for real-time risk visibility, scenario modeling, and automation. Systems track news feeds, regulatory databases, and financial markets for signals that affect your suppliers.

scenario planning tools model potential disruptions. You test how various events impact operations. Which suppliers serve as single points of failure? How quickly can alternative sources be activated?

Technology Foundations

Cloud-based deployment models dominate current offerings. These platforms provide accessibility across locations without significant IT infrastructure investments. Updates and security patches deploy automatically.

AI and machine learning capabilities enhance threat detection. Blue Yonder Luminate offers automated scenario planning and real-time data integration. Algorithms identify patterns humans miss and predict emerging risks based on historical data.

Data analytics dashboards present complex information clearly. Visualisations show risk concentrations, compliance status across supplier portfolios, and trend analysis. Executives access summary views while specialists drill into detailed data.

Why Supply Chain Visibility Matters More Than Ever

Supply chains now span continents and involve hundreds of indirect suppliers. Traditional visibility stops at your direct suppliers. That limitation creates blind spots where significant risks accumulate.

Nth-tier suppliers operate beyond your direct oversight. A component manufacturer’s raw material supplier faces financial difficulties. Your first-tier supplier appears healthy, but their operations depend on this struggling nth-tier provider.

Supply chain risk management software extends visibility downward through these tiers. Multi-tier mapping reveals the complete network. You understand dependencies that would otherwise remain hidden until disruption occurs.

The Cost of Limited Visibility

Financial disruption from supply chain incidents damages more than immediate operations. Stock prices drop when major customers learn about delivery delays. Insurance premiums increase following incidents. Customer relationships suffer permanent damage.

Regulatory penalties compound these costs. Organisations remain responsible for their suppliers’ compliance failures. When a third-party supplier violates data protection regulations or safety standards, your organisation faces penalties and reputational damage.

Operational disruption creates cascading effects. Production lines stop waiting for components. Customer orders go unfilled. Alternative suppliers charge premium rates for expedited service. These costs far exceed investment in preventive risk management systems.

Competitive Advantages From Better Visibility

Organisations with superior supply chain visibility respond faster to emerging threats. They identify issues days or weeks before competitors recognise problems. This advance warning enables proactive mitigation rather than reactive crisis management.

Customer confidence strengthens when you demonstrate robust risk management capabilities. Major buyers increasingly require suppliers to document their supply chain resilience. Organisations using advanced risk management software meet these requirements more easily.

Operational efficiency improves alongside risk reduction. Better visibility reveals redundancies, inefficient routing, and opportunities for consolidation. Risk management systems provide data that drives both safety and performance improvements.

Risk Categories That Demand Active Management

Supply chain risks divide into categories that require different monitoring approaches and mitigation strategies. Effective software addresses multiple risk types through integrated assessment frameworks.

Cybersecurity and Data Protection Risks

Cybersecurity threats targeting suppliers create vulnerabilities throughout your network. A breach at a third-party vendor exposes your data. Ransomware affecting a supplier disrupts your operations.

Supply chain risk management software monitors supplier security postures. Systems track security certifications, conduct vulnerability assessments, and flag incidents. Integration with threat intelligence feeds provides early warning of attacks affecting your supplier network.

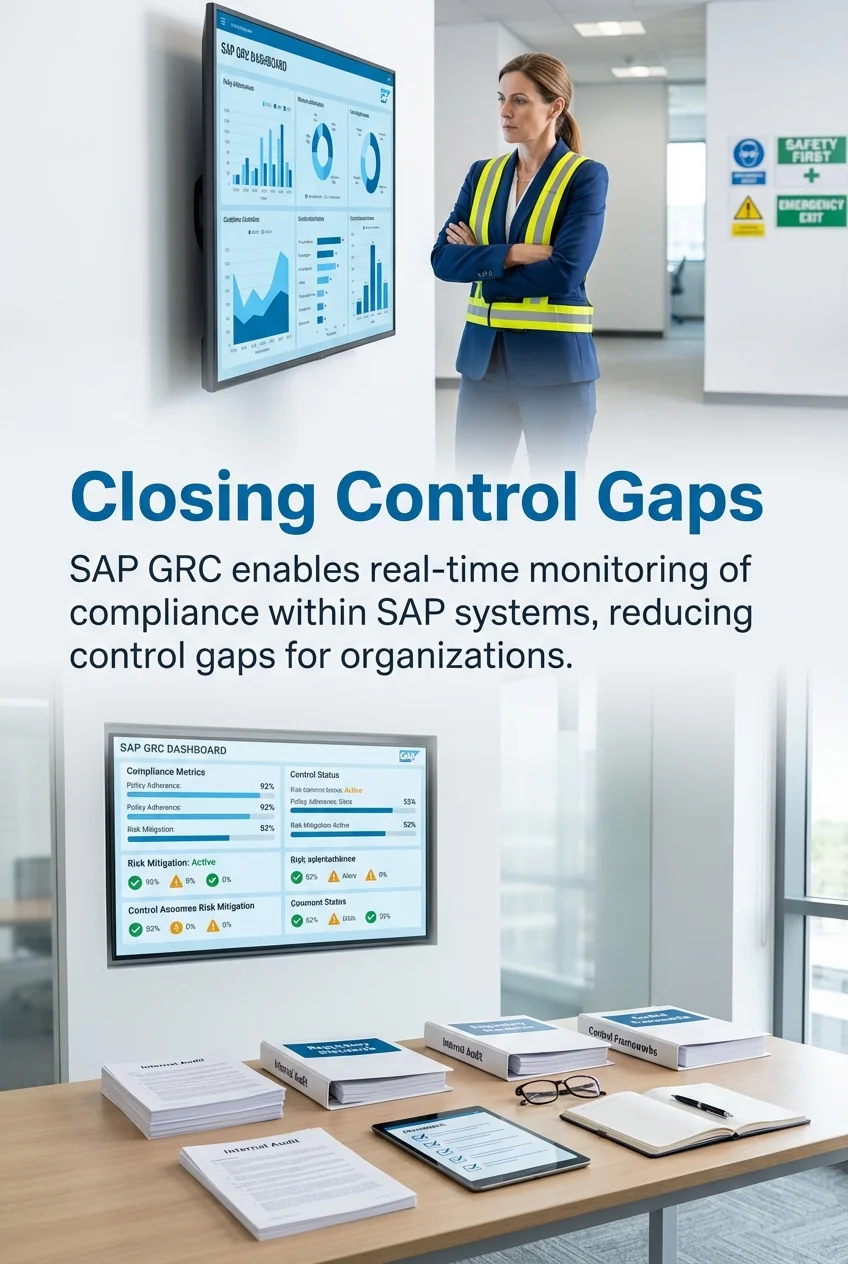

SAP GRC enables real-time monitoring of compliance within SAP systems, reducing control gaps. These capabilities extend to suppliers using similar enterprise systems.

Data protection compliance requires ongoing verification. Suppliers handle sensitive information about your operations and customers. Software platforms automate compliance checking against GDPR, CCPA, and other regulatory frameworks.

Geopolitical and Regulatory Risks

Geopolitical instability affects supply chains through sanctions, trade restrictions, and political unrest. Regulatory changes impact compliance requirements across jurisdictions. These risks evolve rapidly and demand continuous monitoring.

Modern platforms track regulatory databases and government announcements. Automated alerts notify teams when changes affect your supplier locations or product categories. This monitoring covers sanctions lists, export controls, and trade agreements.

Country risk assessments evaluate political stability, legal systems, and economic conditions. Software incorporates these assessments into supplier risk scores. You identify concentration risks in unstable regions before events disrupt operations.

Financial and Operational Risks

Supplier financial instability creates supply disruption risks. A vendor declares bankruptcy. A key supplier struggles with cash flow and cannot fulfil orders. These events cascade through your operations.

Financial monitoring capabilities track supplier credit ratings, payment histories, and financial statement indicators. Early warning systems flag deteriorating financial health before suppliers fail.

Operational risks include capacity constraints, quality issues, and delivery performance. Historical performance data combined with current monitoring reveals patterns. Which suppliers consistently meet commitments? Where do quality problems concentrate?

ESG and Sustainability Risks

Environmental, social, and governance risks affect brand reputation and regulatory compliance. Suppliers using unsustainable practices or violating labour standards create liability for your organisation.

ESG monitoring modules assess supplier performance against sustainability criteria. Carbon emissions, waste management, labour practices, and ethical sourcing receive systematic evaluation. Documentation requirements ensure suppliers maintain appropriate standards.

Sustainability reporting demands visibility into supplier ESG performance. Risk management platforms aggregate this data for regulatory filings and stakeholder communications. You demonstrate commitment to responsible supply chain practices.

Essential Features of Effective SCRM Platforms

Selecting supply chain risk management software requires understanding which capabilities deliver operational value. Essential features separate comprehensive platforms from basic monitoring tools.

Multi-Tier Supplier Mapping

Supplier mapping capabilities visualise relationships across your entire supply network. Direct suppliers connect to their suppliers, revealing the complete chain from raw materials to finished products.

Interactive maps show geographic concentrations, identify single points of failure, and highlight dependency chains. You filter views by product line, risk category, or supplier tier. This visualisation makes complex networks understandable.

Mapping accuracy depends on data collection methods. Leading platforms combine supplier-provided information with third-party data sources. Verification processes ensure maps reflect actual relationships rather than outdated documentation.

Automated Risk Assessment and Scoring

Risk scoring methodologies evaluate suppliers against multiple criteria. Financial stability, compliance history, cybersecurity posture, and operational performance feed into composite scores. These scores prioritise where to focus management attention.

Assessment frequency matters for maintaining current risk profiles. Static annual assessments miss emerging threats. Continuous assessment models update scores as new information becomes available. High-risk suppliers receive more frequent evaluation.

Customisable scoring frameworks adapt to your organisation’s priorities. You weight risk factors according to your industry requirements and risk tolerance. Financial services organisations emphasise cybersecurity while manufacturing companies prioritise operational reliability.

Real-Time Monitoring and Alerting

Monitoring systems track multiple data sources simultaneously. News feeds, social media, regulatory databases, financial markets, and weather services provide signals about emerging threats.

Alert configuration determines how information reaches decision-makers. Critical threats trigger immediate notifications. Lower-priority risks aggregate into daily or weekly reports. Alert fatigue occurs when systems lack proper threshold settings.

Response workflows connect alerts to action plans. When a supplier faces disruption, the system presents alternative sources and escalation procedures. Integration with communication tools enables rapid team coordination.

Compliance Management Capabilities

Compliance modules manage requirements across regulatory frameworks. Systems track which suppliers must meet specific standards. Documentation workflows ensure certificates and audits remain current.

Regulatory change monitoring identifies new requirements affecting your supply chain. When regulations change, the system flags affected suppliers and initiates compliance verification processes.

Audit trail capabilities document compliance activities for regulatory inspections. Who reviewed which supplier? When did assessments occur? What actions were taken to address gaps? Complete documentation protects against penalties.

Integration and Data Management

Integration capabilities determine how well risk management software fits into existing technology ecosystems. APIs connect with procurement systems, ERP platforms, and quality management tools.

Data quality controls ensure accuracy across integrated systems. Duplicate records merge automatically. Inconsistencies flag for review. Master data management maintains a single source of truth about supplier information.

Reporting and analytics tools transform raw data into actionable insights. Standard reports cover common needs while custom analytics address specific questions. Export capabilities support presentations and external reporting requirements.

Building an Effective SCRM Program

Technology platforms provide capabilities, but effective supply chain risk management requires structured implementation. Successful programs combine software tools with governance processes and trained personnel.

Governance and Process Foundations

Governance frameworks define roles, responsibilities, and decision authorities. Who owns supplier risk management? Which teams contribute data? How do escalation procedures work? Clear governance prevents gaps and duplicated efforts.

Risk management processes standardise how your organisation identifies, assesses, and mitigates threats. Documented procedures ensure consistent application across business units and supplier categories. Process maturity develops through continuous improvement cycles.

Policy development establishes risk tolerance levels and acceptable mitigation strategies. These policies guide daily decisions and provide frameworks for evaluating trade-offs between risk and cost.

Technology Implementation Strategy

Implementation planning begins with current state assessment. What supplier data exists? Which systems contain relevant information? Where do manual processes create bottlenecks? Understanding starting conditions shapes realistic implementation timelines.

Phased rollout approaches reduce implementation risk. Start with critical suppliers or high-risk categories. Learn from initial deployment before expanding to the complete supplier base. This approach builds capability while delivering early value.

Change management addresses how people adapt to new systems and processes. Training programs develop user competency. Communication plans explain benefits and address concerns. Executive sponsorship demonstrates organisational commitment.

Data Quality and Supplier Engagement

Data quality determines software effectiveness. Incomplete or inaccurate supplier information produces unreliable risk assessments. Initial data cleanup often represents the largest implementation challenge.

Supplier engagement processes collect and verify information. Self-service portals enable suppliers to update their profiles. Verification procedures confirm accuracy of supplier-provided data.

Ongoing data maintenance prevents quality degradation. Scheduled updates capture changes in supplier circumstances. Automated validation identifies anomalies requiring review. Data governance assigns ownership for maintaining accuracy.

Measuring Program Effectiveness

Performance metrics demonstrate program value and identify improvement opportunities. Lead time from risk identification to mitigation measures responsiveness. Percentage of suppliers with current risk assessments indicates program coverage.

Business impact metrics connect risk management activities to operational outcomes. Avoided disruptions, reduced incident costs, and improved supplier performance quantify program value. These metrics justify continued investment and resource allocation.

Continuous improvement processes use performance data to refine approaches. Which risk indicators prove most predictive? Where do false positives waste resources? Regular program reviews drive capability development.

Evaluating Supply Chain Risk Management Solutions

Defining Your Requirements

Requirements definition starts with understanding your supply chain complexity. How many suppliers do you manage? How many tiers require visibility? Which geographic regions matter most? These factors determine necessary platform capabilities.

Risk priorities vary by industry and organisation. Logistics operations emphasise different risks than manufacturing or retail. Your specific threats should drive feature prioritisation.

Integration needs shape platform selection. Which existing systems must connect with your risk management software? What data flows are required? Technical compatibility affects implementation difficulty and ongoing operational efficiency.

Evaluating Platform Capabilities

Capability assessment examines how well platforms address your requirements. Request demonstrations focused on your specific use cases. Generic presentations miss details that matter for your situation.

Scalability considerations address future growth. Will the platform handle increased supplier counts? Can it adapt to new risk categories or regulatory requirements? Today’s needs differ from requirements in three years.

User experience affects adoption rates. Complex interfaces discourage use. Intuitive designs encourage regular engagement. Trial periods reveal whether your teams can effectively operate the platform.

Understanding Total Cost of Ownership

Hyperproof targets mid-market organizations with governance, risk, and compliance features starting at $12,000 per year. Enterprise platforms often exceed these entry-level costs significantly.

Licensing models vary between vendors. Per-user pricing, supplier-count tiers, and module-based pricing each create different cost structures. Understanding these models helps predict expenses as your program scales.

Implementation costs include software configuration, data migration, integration development, and training. These upfront investments often exceed first-year licensing fees. Budget accordingly to avoid mid-project funding shortages.

Ongoing costs cover licensing renewals, support contracts, and system maintenance. Factor in resources for data management, user support, and continuous improvement activities. Total cost of ownership extends beyond initial purchase price.

Vendor Assessment Factors

Vendor stability matters for long-term platform viability. Established vendors provide confidence but may move slowly on innovation. Newer entrants offer modern capabilities but carry greater risk.

Support and service quality affects operational success. What response times do support contracts guarantee? Are customer success resources available during implementation? Strong vendor support accelerates value realisation.

Customer references provide unfiltered insights. Speak with organisations facing similar challenges. How well did the platform meet expectations? What implementation challenges emerged? Would they select the same vendor again?

Implementation Best Practices

Executive Sponsorship and Stakeholder Alignment

Executive sponsorship provides authority and resources for implementation success. Sponsors remove organisational barriers, resolve conflicts, and maintain priority during competing demands. Identify sponsors early and keep them engaged throughout implementation.

Stakeholder mapping identifies everyone affected by the new system. Procurement, quality, fleet management, finance, and operations all interact with supplier risk management. Understanding stakeholder needs shapes implementation approaches.

Communication planning maintains stakeholder engagement. Regular updates share progress, address concerns, and celebrate milestones. Transparency about challenges builds trust and encourages problem-solving support.

Starting With High-Value Use Cases

Initial use case selection determines early success. Focus on scenarios where risk management software delivers clear, measurable value. Quick wins build momentum and justify continued investment.

Critical supplier management represents a natural starting point. These relationships already receive significant attention. Applying new capabilities to familiar challenges demonstrates value while limiting scope.

High-risk categories benefit immediately from enhanced monitoring. If cybersecurity concerns drive your software investment, start with suppliers handling sensitive data. This focused approach proves value in your priority area.

Managing the Change Journey

Change management addresses how people adapt to new ways of working. Training programs develop skills required for system operation. But training alone doesn’t ensure adoption.

User involvement during implementation builds ownership and identifies practical requirements. Include end users in testing and validation activities. Their feedback improves system configuration and reveals overlooked needs.

Resistance management anticipates and addresses concerns. Some stakeholders fear additional workload. Others worry about transparency revealing their performance. Understanding resistance sources enables targeted responses.

Continuous Improvement Mindset

Initial implementation establishes baseline capability. True value develops through continuous refinement. Regular reviews identify what works well and where adjustments improve effectiveness.

User feedback loops collect operational insights. Which features deliver most value? Where does the system create frustration? This feedback drives configuration adjustments and workflow improvements.

Capability expansion builds on initial success. After core functions operate smoothly, add suppliers, risk categories, or integration points. Measured expansion maintains stability while increasing program value.

Quick Answers to Common Questions

What is software supply chain risk management?

Software supply chain risk management identifies, assesses, and mitigates risks in software development, acquisition, and deployment. This includes monitoring code vulnerabilities, dependencies, and third-party components to ensure integrity, security, and reliability of software products.

What is a supply chain risk management system?

A supply chain risk management system provides structured frameworks and processes for identifying, assessing, mitigating, and monitoring risks throughout your supply chain. These systems ensure operational continuity and resilience against disruptions, vulnerabilities, and compliance failures.

Which software is used in Supply Chain Management?

Supply Chain Management commonly uses platforms like SAP SCM, Oracle SCM Cloud, and IBM Supply Chain Insights. These tools provide planning, procurement, logistics, inventory management, and risk mitigation capabilities supporting end-to-end supply chain operations.

Moving Forward With Supply Chain Risk Management

Supply chain risks will continue evolving as global networks grow more complex. Organisations that invest in proper visibility, monitoring, and response capabilities position themselves to manage threats proactively rather than reactively.

Start by assessing your current risk exposure and visibility gaps. Where do blind spots exist? Which supplier tiers lack proper monitoring? What would major disruptions cost your operations?

Evaluate platforms that address your specific requirements. Focus on capabilities that matter for your industry and risk profile. Remember that systematic management approaches deliver better results than ad-hoc responses.

Build implementation plans that balance ambition with realistic capacity. Phased approaches succeed where comprehensive rollouts often struggle. Quick wins demonstrate value and build momentum for broader deployment.

Your supply chain resilience depends on the visibility and control you establish today. The right software platform provides tools. Your governance, processes, and people determine whether those tools deliver their potential value.