A Safety Management System is a structured framework that identifies workplace hazards, assesses risks, implements controls, and monitors performance to prevent incidents. The four core components work together: Safety Policy establishes organizational commitment and clear objectives, Safety Risk Management identifies hazards and implements controls, Safety Assurance monitors effectiveness through audits and data analysis, and Safety Promotion builds culture through training and communication. Aviation, chemical processing, construction, and marine industries have developed sector-specific frameworks that demonstrate how these components translate into operational reality.

Understanding these systems requires examining how organizations translate regulatory requirements into practical procedures. Each industry faces unique risks that demand tailored approaches while maintaining the core SMS structure.

We’ll examine proven frameworks from multiple sectors, breaking down their components and implementation strategies. You’ll see how different industries apply the same fundamental principles to achieve measurable safety improvements.

What Defines a Safety Management System

A Safety Management System (SMS) is a structured framework designed to manage safety risks in the workplace, supporting continual improvement and compliance with legal and regulatory requirements. This systematic approach moves organizations beyond reactive incident response toward proactive hazard prevention.

The framework establishes formal processes for identifying workplace hazards before they cause harm. Organizations document procedures, assign responsibilities, and create accountability structures that embed safety into daily operations.

Effective SMS implementation requires management commitment backed by allocated resources. Leadership must demonstrate visible support through policy development, resource allocation, and active participation in safety activities.

Documentation forms the backbone of any SMS. Standard operating procedures, risk assessments, incident reports, and audit records create evidence of systematic safety management that satisfies regulatory requirements and supports continuous improvement.

The structured approach enables organizations to measure safety performance through leading and lagging indicators. This data-driven methodology identifies trends, validates control effectiveness, and guides resource allocation decisions.

Core Benefits Beyond Compliance

Organizations that implement robust SMS frameworks typically experience reduced incident rates. Systematic hazard identification catches problems before they escalate into injuries or property damage.

Insurance costs often decrease as insurers recognize proactive safety management. Documented procedures and performance data demonstrate reduced risk profiles that justify premium reductions.

Workplace culture shifts from blame-focused to learning-focused. Employees feel safer reporting hazards and near-misses when they trust the organization will address concerns without punishment.

Operational efficiency improves as safety procedures eliminate wasted time addressing preventable incidents. Streamlined processes reduce disruption and maintain productivity while protecting workers.

The Four Pillars of Every Safety Management System

Every effective SMS rests on four interconnected components that create a complete safety framework. These elements work together to establish, maintain, and improve workplace safety performance.

Understanding how these pillars function individually and collectively provides the foundation for examining industry-specific implementations. Each pillar serves distinct purposes while supporting the others.

Safety Policy: Setting Direction and Commitment

Policy and Planning in a Safety Management System involves establishing a clear safety policy that aligns with regulations and sets objectives for continuous improvement. This documented commitment defines organizational safety vision and establishes accountability.

The policy statement must reflect genuine management commitment. Generic statements that merely satisfy documentation requirements fail to drive meaningful safety improvements across the organization.

Clear safety objectives translate policy into measurable targets. These objectives should be specific, achievable, and linked to resources required for implementation.

Organizational structure assigns safety responsibilities throughout the hierarchy. Everyone from executives to frontline workers must understand their role in maintaining workplace safety.

Safety Risk Management: Identifying and Controlling Hazards

Safety Risk Management (SRM) systematically identifies hazards, assesses their potential consequences, and implements appropriate controls. This proactive process prevents incidents before they occur.

Hazard identification uses multiple methods including workplace inspections, employee reports, incident investigations, and job safety analyses. Diverse input sources capture hazards that single-method approaches might miss.

Risk assessment evaluates each identified hazard’s likelihood and potential severity. This analysis prioritizes control efforts toward the most significant risks facing the organization.

Control hierarchy guides mitigation strategy selection. Elimination and engineering controls receive priority over administrative controls and personal protective equipment.

Risk acceptance decisions involve appropriate management levels. High-risk activities require senior leadership approval with documented justification and monitoring plans.

Safety Assurance: Monitoring and Measuring Performance

Safety Assurance validates that implemented controls work as intended. Regular monitoring, auditing, and data analysis verify SMS effectiveness and identify improvement opportunities.

Internal audits examine compliance with established procedures and regulatory requirements. These systematic reviews identify gaps between documented processes and actual practices.

Performance monitoring tracks leading indicators like near-miss reports and training completion alongside lagging indicators such as injury rates. This balanced approach provides early warning of emerging problems.

Data analysis reveals trends and patterns that inform decision-making. Statistical methods identify whether performance changes represent significant trends or normal variation.

Continuous improvement processes use audit findings and performance data to refine procedures. This feedback loop ensures the SMS evolves to address changing conditions.

Safety Promotion: Building Culture Through Communication

Safety Promotion develops positive safety culture through training, communication, and employee engagement. This pillar transforms documented procedures into consistent workplace behaviors.

Training programs ensure employees possess required competencies. Initial training establishes baseline knowledge while refresher training maintains skills and introduces procedural updates.

Communication channels distribute safety information throughout the organization. Multiple methods including meetings, bulletins, and digital platforms ensure messages reach all employees.

Employee participation mechanisms give workers voice in safety decisions. Safety committees, hazard reporting systems, and consultation processes engage frontline expertise.

Recognition programs reinforce desired safety behaviors. Acknowledging proactive hazard reporting and safety initiative participation encourages continued engagement.

Aviation SMS Framework: The FAA and ICAO Standard

Aviation pioneered structured Safety Management Systems through Federal Aviation Administration and International Civil Aviation Organization standards. This framework has influenced SMS development across multiple industries.

The aviation SMS addresses unique challenges including complex technology, human factors, and high consequence failures. Flight operations require extraordinary reliability that demands systematic safety management.

Aviation-Specific SMS Components

Aviation SMS integrates the four core pillars with sector-specific requirements. Airlines, airports, and maintenance organizations must document how their SMS addresses aviation-specific hazards.

Safety Policy in aviation requires documented commitment from the Accountable Executive. This individual holds ultimate responsibility for SMS implementation and must ensure adequate resources.

Safety Risk Management addresses flight operations, maintenance activities, and ground operations. Risk assessments consider factors like weather, aircraft systems, crew fatigue, and airspace complexity.

Safety Assurance uses flight data monitoring, line operations safety audits, and voluntary reporting systems. These programs capture safety information from normal operations before incidents occur.

Safety Promotion emphasizes crew resource management training. Aviation recognizes human factors as critical elements requiring specific training and procedural controls.

Implementation Results in Aviation

Organizations implementing robust aviation SMS report significant safety performance improvements. Proactive hazard identification systems capture thousands of safety concerns annually that might otherwise go unnoticed.

Data-driven decision making replaces reliance on lagging indicators. Airlines analyze operational data to identify emerging risks and implement targeted interventions.

Just culture principles balance accountability with learning. Pilots and maintenance personnel report errors and hazards without fear of punishment for honest mistakes.

Regulatory acceptance of SMS enables performance-based oversight. Authorities increasingly focus on system effectiveness rather than prescriptive compliance checking.

ISO 45001: The Global Occupational Health and Safety Standard

ISO 45001 provides an international framework for occupational health and safety management systems. This standard applies across industries and integrates with other management system standards.

The standard uses Plan-Do-Check-Act methodology to drive continuous improvement. Organizations establish objectives, implement processes, monitor performance, and refine their approach based on results.

ISO 45001 Core Requirements

Leadership and worker participation form the foundation. Top management must demonstrate commitment while ensuring workers participate in developing and implementing the system.

Planning addresses risk and opportunity identification. Organizations must identify hazards, assess risks, determine legal requirements, and establish objectives with implementation plans.

Support requirements cover resources, competence, awareness, and communication. Documentation controls ensure procedures remain current and accessible to those who need them.

Operation clauses specify how organizations manage operational processes, contractors, and emergency situations. Hierarchy of controls guides risk mitigation strategy selection.

Performance evaluation requires monitoring, measurement, analysis, internal audit, and management review. These elements verify the system functions effectively and achieves intended outcomes.

Benefits of ISO 45001 Certification

Third-party certification demonstrates commitment to recognized international standards. Many clients and supply chain partners require or prefer certified suppliers.

Integration with ISO 9001 quality management and ISO 14001 environmental management creates operational efficiencies. Shared processes reduce duplication while maintaining distinct system objectives.

Global recognition facilitates international business operations. The unified standard eliminates need to comply with multiple national requirements.

Structured improvement framework provides clear roadmap for enhancement. Regular audits and management reviews identify opportunities to strengthen safety performance.

Chemical Industry: OSHA Process Safety Management

OSHA’s process safety Management standard addresses catastrophic risk in facilities using highly hazardous chemicals. This framework prevents releases that could cause fires, explosions, or toxic exposures.

In sectors like chemical or marine, SMS frameworks often include risk management, emergency preparedness, and hazard control tailored to the unique risks of each industry. Process safety focuses on preventing low-probability, high-consequence events.

PSM’s Fourteen Elements

Process safety information documents chemical properties, equipment specifications, and technology details. This technical foundation supports all other PSM elements.

Process hazard analysis systematically evaluates potential failure modes. Teams use methods like HAZOP or What-If analysis to identify scenarios that could cause releases.

Operating procedures provide detailed instructions for normal operations, startups, shutdowns, and emergency situations. These procedures reflect process safety information and hazard analysis findings.

Training ensures employees understand processes, procedures, and emergency response. Refresher training occurs at least every three years or when process changes occur.

Mechanical integrity programs maintain critical equipment through inspection, testing, and preventive maintenance. These programs prevent failures that could trigger catastrophic releases.

Management of change procedures ensure modifications don’t introduce new hazards. Technical review and authorization occur before implementing process or equipment changes.

Incident investigation determines root causes and implements corrective actions. Learning from near-misses and actual incidents prevents recurrence.

Digital Solutions for PSM Compliance

Software platforms help manage PSM complexity. These systems track process safety information, schedule inspections, manage training records, and document hazard analyses.

Automated reminders ensure critical tasks don’t lapse. The system alerts responsible personnel when inspections, tests, or training renewals approach due dates.

Centralized documentation provides instant access to current procedures. Version control prevents use of outdated information that could compromise safety.

Analytics capabilities identify trends in inspection findings, incident patterns, and training effectiveness. Data-driven insights guide resource allocation and program improvements.

Behavior-Based Safety Programs in Action

Behavior-Based Safety focuses on observable worker actions that influence safety outcomes. This approach complements traditional SMS components by addressing the human element.

The methodology recognizes that most incidents result from at-risk behaviors rather than unsafe conditions. Changing these behaviors requires systematic observation, feedback, and positive reinforcement.

BBS Program Structure

Observation process involves peer-to-peer workplace observations using standardized checklists. Observers note safe and at-risk behaviors without blame or punishment.

Immediate feedback helps workers understand risks associated with observed behaviors. Positive reinforcement for safe behaviors proves more effective than punishment for unsafe actions.

Data analysis identifies common at-risk behaviors and underlying system factors. This information guides targeted interventions including training, procedure modification, and engineering controls.

Worker involvement drives program success. Frontline employees participate in developing observation checklists, conducting observations, and analyzing data.

Integration with Broader SMS

BBS programs work best within comprehensive safety management systems. Behavior modification alone won’t overcome inadequate equipment, poor procedures, or organizational pressure for production over safety.

Observation data feeds Safety Assurance processes. Behavior trends indicate whether training, procedures, and controls effectively influence workplace practices.

Management must address system factors that encourage at-risk behaviors. Time pressure, inadequate tools, and conflicting priorities undermine even well-designed BBS programs.

Just culture principles apply to behavior observations. The focus remains on learning and improvement rather than finding individuals to blame.

Construction Safety Management Implementation

Construction presents unique SMS challenges including temporary workplaces, changing hazards, and coordination among multiple contractors. Effective systems adapt core SMS principles to these dynamic conditions.

Project-based work requires rapid SMS deployment. Safety plans must be developed, communicated, and implemented quickly as new projects begin.

Construction-Specific SMS Elements

Pre-job planning identifies project-specific hazards before work begins. This analysis considers site conditions, work sequence, equipment, and worker qualifications.

Site-specific safety plans document identified hazards and required controls. These plans address fall protection, excavation safety, electrical hazards, and coordination with other trades.

Toolbox talks provide regular safety communication. Brief, focused discussions at work start cover daily hazards and reinforce safe work practices.

Multi-employer coordination ensures contractors don’t create hazards for others. Clear communication protocols and site safety meetings facilitate information sharing.

Technology in Construction Safety

Mobile apps enable real-time hazard reporting and safety documentation. Workers photograph hazards and submit reports immediately rather than waiting until day’s end.

Digital inspection checklists ensure consistent safety assessments. Completed forms automatically route to supervisors for review and corrective action assignment.

Wearable technology monitors environmental conditions and worker location. These devices can alert workers to fall hazards, confined spaces, or hazardous atmosphere exposures.

Drones conduct site inspections in hazardous areas. Aerial views identify housekeeping issues, fall hazards, and structural concerns without exposing workers to risk.

Marine Industry Safety Management Approach

Maritime operations use the International Safety Management Code as their SMS framework. This standard applies to ships and shipping companies engaged in international trade.

The ISM Code addresses vessel-specific hazards including enclosed spaces, cargo operations, navigation, and machinery maintenance. Environmental protection requirements integrate with safety management.

ISM Code Key Components

Safety and environmental protection policy establishes company commitment. This policy must be signed by the highest level of management and displayed on all vessels.

Designated person ashore provides shore-based support to masters. This individual monitors vessel safety performance and ensures resources for SMS implementation.

Master’s responsibility and authority receive explicit recognition. The master has overriding authority to make safety and environmental protection decisions.

Emergency preparedness programs address vessel-specific scenarios. Drills verify crew competence in responding to fire, flooding, abandon ship, and pollution situations.

Documentation and Verification

Safety Management Certificate demonstrates SMS implementation. Flag state administrations or recognized organizations audit companies and vessels before issuing certificates.

Document of Compliance verifies shore-based organization meets ISM requirements. This certificate covers all vessels under the company’s management.

Internal audits occur annually while external verification happens at intervals specified by regulations. These audits verify procedures are followed and identify improvement opportunities.

Non-conformity reporting and corrective action processes address identified deficiencies. Root cause analysis prevents recurrence of system failures.

Building Your SMS: Practical Implementation Steps

Developing an effective Safety Management System requires systematic planning and stakeholder engagement. The process takes time but following structured steps increases success likelihood.

Start by assessing current safety practices against SMS requirements. This gap analysis identifies existing strengths and areas needing development.

Phase One: Foundation Development

Secure management commitment through executive briefings. Leaders must understand SMS benefits, resource requirements, and their specific responsibilities.

Form implementation team with representatives from operations, maintenance, human resources, and safety. Diverse perspectives ensure the system addresses all organizational areas.

Define SMS scope and boundaries. Determine which activities, locations, and organizational units the system will cover.

Develop safety policy statement reflecting organizational commitment. This document should be concise, memorable, and signed by the chief executive.

Phase Two: Documentation and Procedures

Document existing safety procedures that already meet SMS requirements. Many organizations have informal practices that simply need documentation and formalization.

Develop required procedures for identified gaps. Involve workers who perform the tasks to ensure procedures reflect operational reality.

Create forms and records supporting SMS processes. Standardized templates ensure consistent documentation across the organization.

Establish document control system managing procedure revisions. Version control prevents use of outdated information.

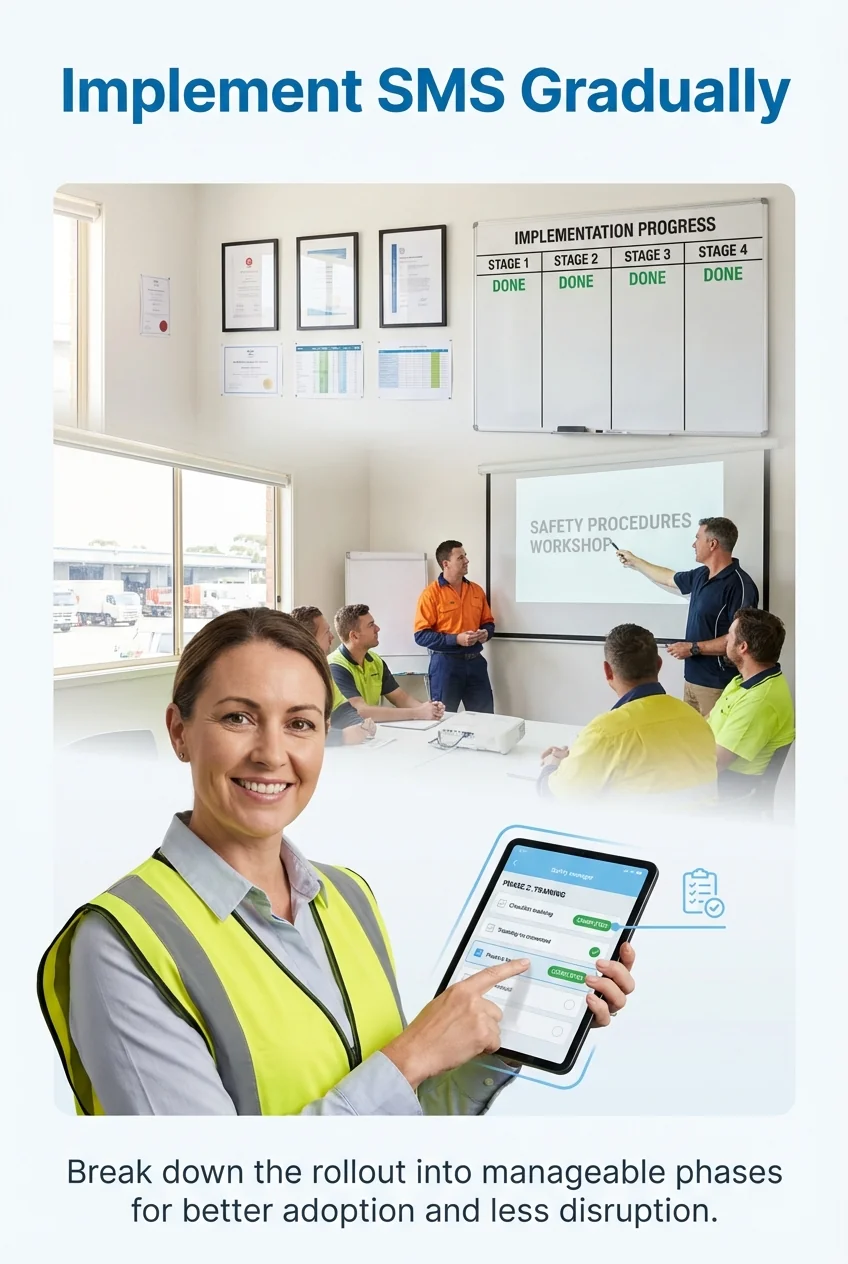

Phase Three: Training and Rollout

Train management on SMS principles and their leadership role. Executives and supervisors must understand how to support implementation.

Conduct worker training on SMS components and their participation role. Emphasize how the system protects them and values their input.

Implement SMS gradually rather than attempting everything simultaneously. Phased rollout allows learning and adjustment before expanding scope.

Establish performance monitoring before full implementation. Baseline data enables measuring improvement after SMS becomes operational.

Phase Four: Monitoring and Improvement

Conduct internal audits evaluating SMS effectiveness. These reviews identify what works well and what needs refinement.

Analyze safety performance data for trends. Leading and lagging indicators reveal whether the system achieves intended outcomes.

Hold management review meetings assessing SMS performance. Senior leadership examines audit findings, performance data, and resource adequacy.

Implement continuous improvement actions based on review findings. The system should evolve to address changing conditions and emerging best practices.

Key Questions About Safety Management Systems

What are the 5 elements of a safety management system?

The five elements include policy and planning, implementation and operation, monitoring and evaluation, review and continual improvement, and employee involvement. These elements create a structured approach to identifying hazards, managing risks, ensuring compliance, and fostering proactive safety culture.

What is an example of a safety system?

The SHELL model integrates procedures, equipment, environment, and human factors to prevent workplace incidents. This model helps organizations identify and address mismatches between people, processes, and technology to enhance overall safety performance.

Moving Forward with Your Safety Management System

Building an effective SMS takes commitment, but the framework provides clear direction. Start with management buy-in and gap analysis to understand your current position.

Focus on one pillar at a time rather than attempting everything simultaneously. Solid foundation in Safety Policy enables effective Risk Management implementation.

Engage workers throughout the process. Their operational knowledge identifies practical solutions that theoretical approaches miss.

Measure progress through both leading and lagging indicators. This balanced approach shows whether your efforts translate into improved safety performance.

Your first step today is assessing management commitment. Without leadership support, even well-designed systems fail to achieve their potential.

Consider how examples from aviation, chemical, construction, and marine sectors apply to your operations. Adapt proven approaches rather than creating everything from scratch.

The investment in systematic safety management delivers returns through reduced incidents, lower costs, and stronger operational performance. Organizations that treat SMS as strategic advantage rather than compliance burden achieve superior results.

Visit our guide on why SMS matters to understand the broader business case for structured safety management. For transport operations, explore our Chain of Responsibility safety system resources that demonstrate industry-specific implementation. Learn about heavy vehicle safety compliance frameworks that show SMS principles in action.