Your Heavy Vehicle National Law compliance starts with knowing what to check. Any person who has influence over heavy vehicle transport activities shares a legal duty to ensure safety under the HVNL. This checklist covers mass limits, load restraint, fatigue management, speed compliance, vehicle maintenance, and duty holder responsibilities. It provides audit tools, role-based matrices, and documentation requirements for transport operators, safety managers, and supply chain professionals.

Twenty-five years in supply chain operations taught me that compliance checklists fail when they sit in filing cabinets. They work when operators integrate them into daily workflows, from pre-start inspections to contract negotiations.

This guide delivers actionable verification steps for each Chain of Responsibility duty area. You’ll get practical tools for mass checking, load restraint assessment, fatigue monitoring, and maintenance tracking. Each section connects regulatory requirements to operational reality, the way actual transport businesses manage compliance under the HVNL.

Understanding Chain of Responsibility Duty Holders

Chain of Responsibility under the HVNL creates shared legal obligations across the transport supply chain. Consignors, packers, loaders, schedulers, carriers, and receivers all hold duties when they influence transport activities.

The 2018 CoR amendments introduced a primary duty. CoR was strengthened in October 2018 with amendments introducing a primary duty for safety in transport activities. This primary duty requires parties to eliminate or minimize public risks arising from their transport activities.

Executive officers face specific due diligence obligations. Company directors must ensure their organization implements systems to manage CoR duties. This includes providing resources, verifying compliance systems work, and maintaining current knowledge of HVNL requirements.

Identifying Your CoR Role

You hold CoR duties if you control or influence any transport activity aspect. Consignors decide delivery timeframes. Schedulers create driver run sheets. Loading managers supervise restraint procedures. Each role carries specific compliance obligations.

Multiple parties often share CoR duties for single transport tasks. A retailer scheduling deliveries holds scheduler duties. Their warehouse supervisor loading trucks holds loader duties. The transport company operating the vehicle holds carrier duties. All three parties must manage their respective obligations.

Primary Duty Requirements

The primary duty requires you to ensure safety so far as reasonably practicable. This means eliminating risks where possible, or minimizing them when elimination isn’t practical.

Reasonably practicable considers likelihood and degree of harm, what you know about risks, available risk controls, and costs of controls relative to the risk. You can’t claim ignorance as a defense.

| Duty Holder | Primary Influence Area | Key CoR Obligations |

|---|---|---|

| Consignor | Delivery requirements, packaging specifications | Reasonable delivery timeframes, accurate documentation, load compatibility |

| Packer | Load configuration, container selection | Weight distribution, load stability, dimension compliance |

| Loader | Physical loading, restraint application | Load restraint standards, mass compliance verification, vehicle capacity |

| Scheduler | Journey planning, driver assignments | Fatigue law compliance, speed compliance allowances, realistic timeframes |

| Carrier | Vehicle operation, driver management | Vehicle maintenance, driver licensing, work diary compliance, speed management |

| Receiver | Unloading requirements, site access | Safe unloading facilities, reasonable timeframes, mass verification processes |

Mass and Dimension Compliance Verification

Mass compliance starts before loading begins. You need current weight limits for the vehicle configuration, route restrictions, and accurate product weights.

Check the vehicle’s mass management accreditation status. Accredited vehicles use certified weighing systems. Non-accredited vehicles require public weighbridge verification or approved portable weighing equipment.

Pre-Loading Mass Checks

Verify vehicle tare weight before loading. Compare the weighbridge docket or load cell reading against vehicle registration documents. Discrepancies indicate potential compliance issues or documentation errors.

Calculate available payload capacity. Subtract tare weight and fuel weight from the gross vehicle mass limit. Add axle group limits and bridge formula calculations for multi-axle configurations.

Confirm product weights match documentation. Physical package labels, supplier declarations, and warehouse management system data should align. A 2% variance triggers re-verification requirements under most Chain of Responsibility frameworks.

Dimension Compliance Requirements

Standard dimension limits are 2.5 meters wide, 4.3 meters high, and 19 meters long for rigid trucks. B-double combinations extend to 26 meters. Your route and vehicle configuration determine applicable limits.

Measure load overhang at the rear. Projections beyond 1.2 meters require warning devices. Projections beyond 3.7 meters require pilot vehicles and notice to road managers.

| Compliance Element | Verification Method | Frequency |

|---|---|---|

| Gross Vehicle Mass | Weighbridge or certified load cells | Every loaded departure |

| Axle Group Weights | Individual axle weighing or distribution calculation | Every loaded departure |

| Product Weight Accuracy | Sample weighing, supplier declaration verification | New products, quarterly audits |

| Height Clearance | Physical measurement, bridge height databases | Route planning, load configuration changes |

| Width Compliance | Physical measurement at widest point | Load configuration changes, non-standard cargo |

Load Restraint Assessment and Verification

Load restraint prevents cargo movement during normal driving conditions. The Load Restraint Guide specifies performance standards for different load types and vehicle configurations.

Your restraint system must withstand forces in all directions. Forward forces during braking reach 0.8g. Rearward forces during acceleration hit 0.5g. Lateral forces during cornering reach 0.5g. Vertical forces account for road irregularities.

Restraint System Components

Direct restraint uses physical barriers. Headboards, gates, and bulkheads contain loads. These structures must handle the required forces for the cargo weight.

Indirect restraint uses tie-downs. Chains, straps, and ropes create downward force. This friction prevents load movement. The Load Restraint Guide provides calculation methods for required tie-down capacity.

Combination restraint uses both methods. Palletized goods often need headboard protection plus strap restraint. Containerized freight combines container twist-locks with load distribution inside the container.

Load Restraint Inspection Points

Check tie-down anchorage points before loading. Inspect for cracks, deformation, or corrosion. Vehicle manufacturer specifications define safe working loads for each anchor point.

Verify restraint equipment condition. Chains need manufacturer markings visible. Straps can’t have cuts or excessive wear. Rated capacity must exceed calculated requirements from the Load Restraint Guide.

Document restraint methods used. Note tie-down positions, tension applied, and blocking used. This documentation proves compliance and supports CoR training when you review effective practices.

- Measure load dimensions and calculate weight distribution

- Select appropriate restraint method from Load Restraint Guide

- Verify restraint equipment meets required working load limits

- Apply restraint with proper technique and tension

- Inspect restraint before departure and at rest stops

- Document restraint method, equipment used, and inspection results

Fatigue Management Compliance

Fatigue management under the HVNL requires work and rest hour compliance. Drivers use work diaries or electronic work diary systems to record work, rest, and driving time.

Standard hours allow 12 hours work in 24 hours, with mandatory rest breaks. Solo drivers need 7 continuous hours rest in each 24-hour period. Two-up operations have different requirements when both drivers are present.

Scheduler Fatigue Obligations

Your schedules must allow drivers to comply with work and rest requirements. Build in buffer time for traffic, delays, and unexpected events. Tight schedules that force speeding or skipped rest breaks create CoR breaches.

Review actual journey times against scheduled times monthly. Consistent over-runs indicate unrealistic scheduling. This data helps you adjust schedules before drivers face compliance pressure.

Verify driver work diary compliance before assigning additional work. A driver who just completed a 12-hour shift can’t legally start another shift without required rest. Schedulers who assign work knowing rest requirements aren’t met breach CoR duties.

Work Diary and EWD Verification

Check work diary completion daily. Drivers must record work and rest times within required timeframes. Missing entries, unclear entries, or obvious errors need immediate correction.

Electronic work diary systems automate much of this tracking. The system links to vehicle telematics, recording driving time automatically. Manual entries still occur for non-driving work time.

Maintain work diary records for three years. NHVR audits request historical records. Electronic storage systems simplify this requirement compared to paper diary retention.

| Fatigue Requirement | Standard Hours | Verification Method |

|---|---|---|

| Maximum work time | 12 hours in 24 hours | Work diary total, EWD system report |

| Minimum rest break | 7 continuous hours in 24 hours | Work diary entries, EWD rest period calculation |

| Maximum driving time | 5.5 hours without break | Telematics data, work diary driving entries |

| Rest break requirements | 15 minutes stationary every 5.5 hours driving | Work diary break entries, EWD stationary periods |

Speed Compliance Monitoring Systems

Speed compliance protects your CoR position and driver safety. Schedulers must allow legal speed limit compliance. Carriers must implement speed monitoring systems.

Telematics systems track vehicle speed continuously. Set alert thresholds at posted speed limits for routes. Configure systems to flag repeated speeding events, not isolated instances.

Speed Limiter Requirements

Vehicles over 4.5 tonnes GVM manufactured after 1991 need speed limiters. The limiter must restrict maximum speed to 100 km/h. Annual inspections verify limiter function and seal integrity.

Check speed limiter certification during vehicle inspections. The limiter must be type-approved and properly sealed. Tampering with speed limiters creates serious CoR breaches.

Route-Based Speed Management

Map speed limits for regular routes. School zones, roadwork areas, and local restrictions change frequently. Update route speed data quarterly or when drivers report changes.

Calculate realistic journey times using route speed limits. Add time for mandatory rest breaks, typical traffic conditions, and loading or unloading duration. Unrealistic schedules that require speeding breach scheduler CoR duties.

Review telematics speed data monthly. Identify routes with frequent speeding events. This analysis reveals whether speed limits are unrealistic, driver behavior needs addressing, or route selection needs changing.

Vehicle Maintenance and Roadworthiness Standards

Vehicle maintenance obligations fall primarily on carriers, but consignors and schedulers hold duties too. You can’t use vehicles you know are unroadworthy or likely to become unroadworthy during the planned journey.

Establish preventive maintenance schedules based on manufacturer recommendations. Heavy vehicles need more frequent servicing than light vehicles. Document all maintenance work with date, work performed, parts replaced, and next service due.

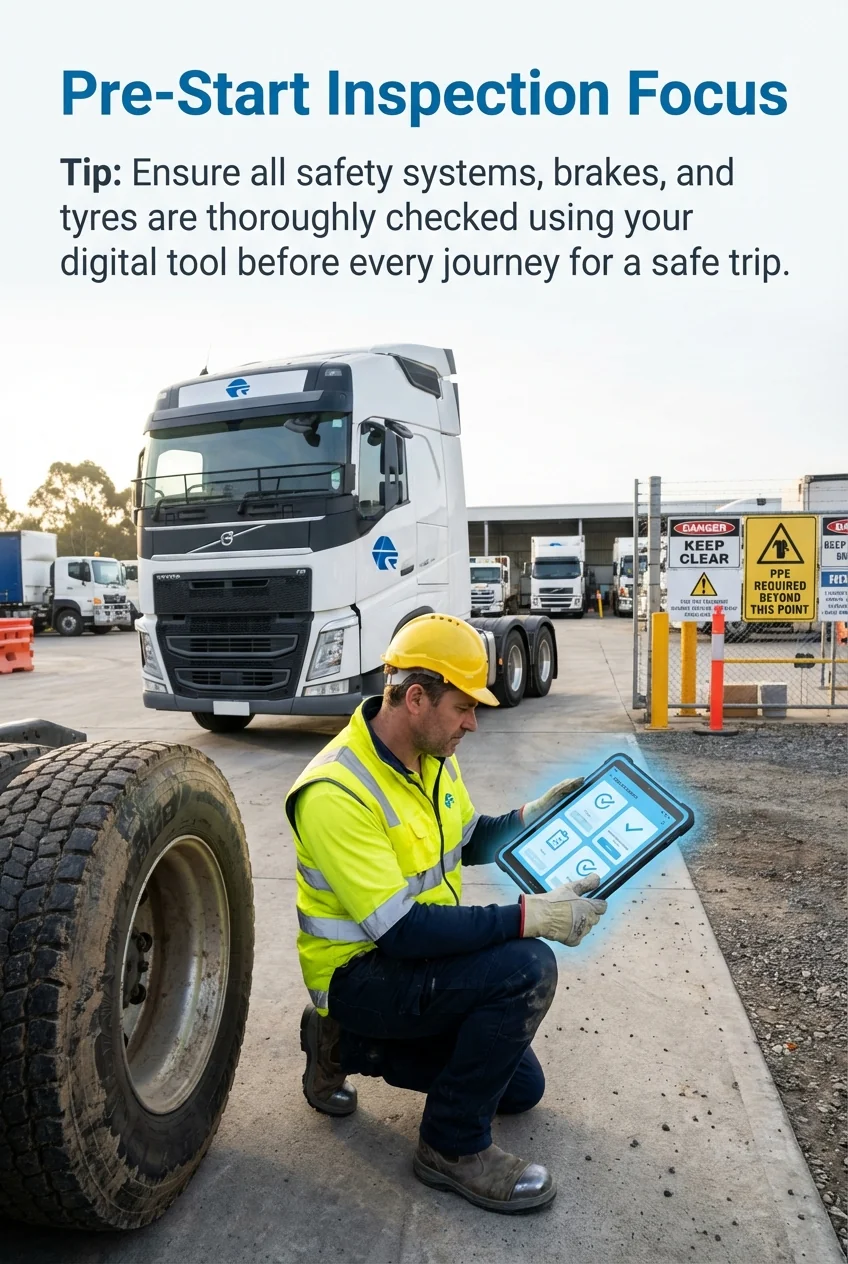

Pre-Start Inspection Requirements

A truck pre-operational checklist typically covers brakes, steering, tyres, lights, indicators, and mirrors. Drivers complete these checks before each journey. Document inspection results and any defects identified.

Critical safety items need immediate attention. Brake defects, steering problems, and significant oil leaks prevent departure. Non-critical items like minor exterior damage can be scheduled for repair if they don’t affect safety.

Create simple inspection forms drivers can complete in 10 minutes. Complex forms reduce completion rates. Focus on items that affect safe operation, not cosmetic concerns.

Service and Repair Documentation

Keep complete service histories for each vehicle. Record dates, odometer readings, work performed, parts used, and technician details. This documentation proves your maintenance system operates effectively.

Track component replacement intervals. Major items like brake shoes, bearings, and steering components have predictable wear patterns. Replace them before failure, not after breakdown.

Maintain records for vehicle lifetime plus three years after disposal. CoR audits examine maintenance history to verify systematic approaches to roadworthiness.

- Schedule preventive maintenance based on manufacturer intervals

- Document all pre-start inspections with defect recording

- Track component wear and replace before failure

- Maintain service records for all maintenance and repairs

- Verify annual inspection currency and display certificates

Driver Licensing and Competency Verification

Carriers must verify driver licensing before employment and regularly during employment. Different heavy vehicle classes require specific license endorsements. Check licenses match vehicle types driven.

Verify medical fitness currency. Drivers over 45 need annual medicals. Conditional licenses restrict driving based on medical conditions. Confirm these restrictions don’t conflict with assigned duties.

License Verification Processes

Check licenses physically, not just copies. Validate license numbers through state licensing authority databases. This confirms license status, class, conditions, and demerit points.

Conduct license checks at hiring and quarterly thereafter. Set calendar reminders for each driver. Missing an expired license creates carrier CoR breaches and invalidates insurance.

Document license verification in driver files. Note check date, license number, class, expiry date, and any conditions. Include database confirmation screenshots as evidence.

Competency Assessment Requirements

Assess driver competency for specific vehicle types and operations. A driver licensed for rigid trucks needs additional assessment before operating articulated vehicles.

Conduct practical assessments for new hires. Observe coupling procedures, load restraint application, and defensive driving techniques. Document assessment outcomes and areas needing improvement.

Provide regular CoR training covering fatigue management, mass limits, load restraint, and speed compliance. Training demonstrates your due diligence and keeps drivers current with HVNL requirements.

Risk Assessment and Management Plans

Risk assessment identifies hazards in your transport operations. Management plans document controls you implement to eliminate or minimize identified risks.

Transport risk assessments cover route hazards, vehicle suitability, driver competency, weather conditions, and cargo characteristics. Assess risks before operations begin, then review regularly.

Transport Risk Identification

Map your transport activities end-to-end. Start with consignment receipt, through loading, journey planning, delivery, and return. Identify decision points where CoR duties apply.

List potential breaches at each decision point. Unrealistic delivery times create fatigue pressure. Inadequate restraint equipment causes load shift. Poor vehicle maintenance leads to breakdowns.

Assess likelihood and consequence for each risk. High likelihood and high consequence risks need immediate controls. Low likelihood and low consequence risks may only need periodic review.

Control Implementation and Monitoring

Select appropriate controls for identified risks. Elimination controls remove the hazard completely. Substitution controls replace risky processes with safer alternatives. Engineering controls use physical barriers or automated systems.

Administrative controls include procedures, training, and supervision. Personal protective equipment is the last control option when other methods don’t adequately reduce risk.

Monitor control effectiveness monthly. Review incident reports, near-misses, and compliance data. Ineffective controls need replacement or supplementation with additional measures.

| Risk Category | Common Hazards | Control Examples |

|---|---|---|

| Mass compliance | Overloading, incorrect weights, inadequate equipment | Weighbridge protocols, product weight verification, payload management systems |

| Load restraint | Inadequate tie-downs, poor technique, equipment failure | Restraint equipment inspections, loading procedures, competency training |

| Fatigue management | Tight schedules, unrealistic timeframes, inadequate rest | Schedule reviews, buffer time allocation, work diary monitoring |

| Speed compliance | Unrealistic schedules, route pressures, driver behavior | Telematics monitoring, realistic journey planning, speed alerts |

| Vehicle maintenance | Deferred maintenance, inadequate inspections, component wear | Preventive maintenance schedules, pre-start checks, service tracking |

Record Keeping and Documentation Requirements

HVNL requires records proving CoR compliance. Keep evidence of management systems, training delivery, inspections completed, and corrective actions taken.

Retention periods are three years for most CoR records. Some records like driver license verifications and vehicle maintenance histories need longer retention.

Essential CoR Records

Maintain delivery dockets with accurate load descriptions and weights. Include consignor and consignee details, delivery timeframes, and special requirements. These documents prove you set reasonable expectations.

Keep weighbridge dockets for every loaded departure. Electronic weighbridge systems can automatically store this data. Paper dockets need organized filing systems with quick retrieval capability.

Document all load restraint applications. Photos of tied-down loads provide excellent evidence. Include restraint equipment specifications and calculation worksheets from the Load Restraint Guide.

Training and Competency Records

Record all CoR training delivered to staff. Note training date, content covered, participants, and assessment results. Keep course materials and participant acknowledgment forms.

Document driver competency assessments. Include assessment criteria, observation notes, and outcomes. Track refresher training dates and re-assessment schedules.

Maintain training registers showing who received what training and when. This register proves your systematic approach to building CoR competency across your organization.

Audit and Inspection Documentation

Keep internal audit reports showing compliance verification activities. Document what you checked, findings, non-conformances identified, and corrective actions implemented.

Retain external audit reports from NHVR compliance reviews or accreditation audits. Track corrective action completion and provide evidence of improvements made.

File inspection reports for vehicles, restraint equipment, and facilities. Regular inspections demonstrate proactive management of roadworthiness and load security.

Audit and Compliance Verification Processes

Regular internal audits verify your CoR management system works effectively. Schedule audits quarterly for high-risk areas and annually for lower-risk elements.

Audit scope should cover all CoR duty areas relevant to your operations. Don’t just audit easy areas. Focus audit time on areas with highest breach consequences or recent incidents.

Internal Audit Planning

Develop audit checklists aligned to this CoR compliance checklist. Each checklist item needs corresponding evidence requirements and assessment criteria.

Assign auditors with appropriate competency. They need CoR knowledge, your operational understanding, and objectivity. External consultants provide independence for periodic reviews.

Schedule audits to minimize operational disruption while ensuring representative sampling. Audit during normal operations, not special circumstances or quiet periods.

Non-Conformance Management

Document all compliance gaps identified during audits. Classify by severity – critical breaches need immediate action, minor issues can follow normal improvement processes.

Assign responsibility for corrective actions with specific completion dates. Track action completion and verify effectiveness before closing non-conformances.

Analyze trends in non-conformances. Repeated issues indicate system failures needing fundamental changes, not just corrective actions for individual instances.

NHVR Compliance Activities

NHVR leadership has signalled a stronger focus on data-driven regulation and higher supply-chain accountability. Expect increased compliance activities targeting duty holders beyond carriers.

Prepare for desk audits requesting documentation. NHVR can require delivery records, weighbridge dockets, maintenance logs, and training records. Organized record systems enable quick response.

Roadside inspections check vehicle roadworthiness, load security, driver licensing, and work diary compliance. Ensure drivers carry required documents and understand their CoR obligations.

Technology Solutions for CoR Management

Management systems like CoRGuard track CoR obligations across your supply chain. These platforms centralize compliance data, automate alerts, and generate audit reports.

Telematics systems monitor vehicle location, speed, and driving behavior. Integration with work diary apps creates automated fatigue management. Real-time alerts enable proactive intervention before breaches occur.

Weighing Technology Options

Onboard weighing systems use load cells or air suspension sensors. These systems display real-time weight during loading. Accuracy within 2% meets most compliance requirements.

Portable axle scales provide verification without weighbridge access. Position scales under axle groups and read weights directly. These scales suit remote operations or periodic verification.

Weighbridge integration with transport management systems automates weight recording. Data flows directly from weighbridge to dispatch systems, eliminating manual entry and improving accuracy.

Electronic Work Diary Systems

EWD systems link to vehicle systems, recording driving time automatically. Drivers manually enter rest periods and non-driving work. The system calculates remaining available hours.

Choose EWD systems approved by NHVR. Approved systems meet accuracy standards and record requirements. Non-approved systems don’t satisfy HVNL obligations.

Train drivers thoroughly on EWD operation. Incorrect manual entries create compliance issues despite automated features. Regular audits verify drivers use systems correctly.

Procurement and Contractor Management

Your CoR duties extend to contractors and subcontractors you engage. Due diligence requires verification that contractors have adequate CoR management systems.

Include CoR requirements in transport contracts. Specify compliance standards, documentation requirements, and audit rights. Contracts shift some compliance burden to contractors while maintaining your oversight duties.

Contractor Pre-Qualification

Assess contractor CoR capabilities before engagement. Request evidence of accreditation, insurance currency, safety systems, and recent audit results.

Verify contractor vehicles meet roadworthiness standards. Check maintenance records, inspection certificates, and vehicle age. Poor vehicle condition indicates inadequate maintenance systems.

Review contractor incident history. Frequent breaches or safety incidents reveal systemic problems. These contractors pose compliance and reputational risks.

Ongoing Contractor Monitoring

Audit major contractors annually. Review their CoR management systems, training records, and compliance documentation. Document audit findings and track improvement actions.

Monitor contractor performance metrics monthly. Track delivery timeframes, load rejections, vehicle defects, and safety incidents. Performance decline triggers increased oversight or contract review.

Maintain contractor compliance registers. Record pre-qualification evidence, audit dates, incidents, and contract renewal decisions. This register demonstrates your ongoing due diligence.

Building Sustainable Compliance Culture

Technical compliance checklists only work when your organization values safety and compliance. Culture drives behavior when supervisors aren’t watching.

Leadership commitment shows through resource allocation, priority setting, and consequences for non-compliance. Executives who cut corners signal that compliance is optional.

Embedding Compliance in Operations

Integrate CoR checks into existing workflows. Dispatchers verify driver hours before assignment. Warehouse supervisors confirm weighbridge dockets before releasing vehicles. Procurement staff assess contractor CoR systems before engagement.

Provide tools that make compliance easier than non-compliance. Simple checklists, automated alerts, and accessible documentation reduce compliance friction.

Recognize and reward good compliance practice. Drivers who consistently manage fatigue well and maintain vehicles deserve acknowledgment. Positive reinforcement builds compliance culture more effectively than punishment alone.

Learning from Incidents and Near-Misses

Investigate all compliance breaches and near-misses. Identify root causes, not just immediate failures. Did system deficiencies enable the breach? Was training inadequate? Did competing priorities create pressure?

Share lessons learned across your organization. Incident reports become training case studies. Near-miss discussions in team meetings build awareness without blame.

Track corrective action effectiveness. Did the changes prevent recurrence? Ineffective corrections indicate deeper systemic issues needing attention.

Heavy vehicles are involved in around one in five road crash fatalities. Your CoR compliance directly contributes to road safety outcomes. The systems you build today protect your drivers, other road users, and your business sustainability.

Taking Action on Chain of Responsibility

This checklist provides the framework for HVNL compliance across your transport operations. Start by identifying your specific CoR duty holder roles. Map your current practices against each section of this guide.

Prioritize areas with highest risk or largest gaps. Mass compliance and load restraint typically need immediate attention. Fatigue management and vehicle maintenance follow closely. Documentation and record-keeping enable verification of everything else.

Build your compliance system systematically. Implement mass verification processes before launching complex technology solutions. Establish basic maintenance schedules before pursuing accreditation programs. Each step creates foundation for the next level.

Review this checklist quarterly. CoR requirements evolve through regulatory updates and enforcement focus changes. Your operations change through new contracts, different vehicle types, and altered routes. Regular reviews keep your compliance current.

Working through detailed CoR compliance across mass, load restraint, fatigue, speed, and maintenance creates the documented evidence NHVR looks for. Your systematic approach to each duty area demonstrates the due diligence that protects your organization and supports transport safety.