transport safety management requires more than basic compliance. It demands structured systems, technology integration, and a leadership commitment to continuous improvement.

Transport operations face evolving safety challenges. Driver Fatigue, Vehicle maintenance gaps, and distracted driving remain persistent risks. Effective safety management integrates regulatory compliance with practical operational strategies.

This guide provides ten actionable transport safety management tips. Each tip reflects current industry practices and regulatory frameworks. You’ll learn how to develop safety culture, implement technology solutions, and manage driver performance effectively.

1. Build Leadership Commitment to Safety Culture

Safety culture starts at the executive level. Management must demonstrate visible commitment through resource allocation and policy enforcement.

Leadership actions communicate organizational priorities. When executives participate in safety meetings, review incident reports, and support training investments, they signal that safety matters beyond compliance documentation.

Allocate budget for safety initiatives. Include safety performance in leadership KPIs. Schedule regular executive reviews of safety metrics. This accountability structure ensures safety remains a strategic priority.

Recognize employees who identify hazards or suggest improvements. Create reporting channels that protect workers from retaliation. Safety culture thrives when workers trust the system.

Practical Leadership Actions

Hold monthly safety committee meetings with cross-functional representation. Review incident trends and near-miss reports. Assign action items with deadlines and ownership.

Include safety performance in manager evaluations. Link compensation to safety outcomes. This creates accountability at every management level.

Communicate safety expectations clearly. Publish safety policies in accessible formats. Ensure all workers understand their responsibilities under your safety management system.

2. Implement Regular Vehicle Maintenance Programs

Vehicle maintenance prevents mechanical failures that cause incidents. Structured maintenance programs reduce breakdown risks and extend asset life.

Establish maintenance schedules based on manufacturer recommendations and operational demands. Track maintenance history for each vehicle. Use this data to identify recurring issues and optimize replacement cycles.

Conduct daily pre-trip and post-trip inspections. Train drivers to identify brake system issues, tire wear, and fluid leaks. Empower drivers to remove unsafe vehicles from service.

Document all maintenance activities. Maintain records for regulatory compliance and warranty claims. Digital maintenance management systems improve tracking accuracy and reporting capabilities.

Critical Maintenance Components

Focus on safety-critical systems. Brake systems require regular inspection and immediate repair when issues arise. Tire rotation and replacement prevent blowouts that cause loss of control.

Monitor fluid levels systematically. Oil, coolant, and brake fluid degradation affects vehicle performance. Establish replacement intervals based on usage patterns.

Address minor issues promptly. Small problems escalate when ignored. A systematic approach to repairs prevents costly breakdowns and safety incidents.

3. Develop Driver Training and Education Programs

Driver capability directly impacts safety outcomes. Structured training programs improve skills and reinforce safe behaviors.

Provide comprehensive onboarding for new drivers. Cover vehicle operation, company safety policies, and regulatory requirements. Assess competency before assigning independent duties.

Deliver ongoing training throughout employment. Address emerging risks, new equipment, and regulatory changes. Use varied formats including classroom sessions, online modules, and behind-the-wheel coaching.

Training programs should address defensive driving techniques. Teach drivers to anticipate hazards and maintain safe following distances. Cover blind spot awareness and lane change protocols.

Training Program Components

Include fatigue management education. Drivers need to recognize early fatigue symptoms and understand the importance of rest breaks. This knowledge complements regulatory hours-of-service requirements.

Address distracted driving prevention. Establish clear policies on mobile phone use and other distractions. Explain how attention lapses contribute to incidents.

Provide training on work zone safety. Construction zones require heightened awareness and speed reduction. Drivers should understand traffic control devices and appropriate responses.

4. Combat Driver Fatigue Through Systematic Management

Driver fatigue degrades alertness and reaction time. Systematic fatigue management protects drivers and other road users.

Understand regulatory requirements. Hours-of-service regulations set maximum driving periods and minimum rest requirements. Compliance forms the foundation of fatigue management.

Monitor driver schedules proactively. Identify patterns that may indicate fatigue risk. Consider factors beyond regulatory limits including route difficulty and time of day.

Encourage drivers to prioritize sleep quality. Provide resources on sleep hygiene and fatigue recognition. Create a culture where drivers feel comfortable reporting fatigue.

Fatigue Risk Factors

Night driving increases fatigue risk. Circadian rhythms affect alertness during overnight hours. Schedule adequate recovery time after night shifts.

Long continuous driving periods create cumulative fatigue. Break long routes into manageable segments. Plan rest stops strategically.

Environmental factors contribute to fatigue. Heat, noise, and vibration increase physical stress. Address these factors through vehicle selection and maintenance.

5. Leverage Technology and Telematics Solutions

Technology provides objective data for safety management. Generative AI is being tested in California’s Department of Transportation programs to make use of sensor and camera data for safety interventions.

Telematics systems track vehicle location, speed, and operational parameters. This data enables proactive safety management and coaching opportunities.

Dashboard cameras provide incident documentation and driver coaching opportunities. Forward-facing cameras capture roadway conditions. Driver-facing cameras identify distracted driving and fatigue indicators.

GPS tracking enables route optimization and improved response to breakdowns. Real-time location data supports customer communication and operational efficiency.

Technology Implementation Strategies

Introduce technology with clear communication about safety objectives. Address driver privacy concerns transparently. Focus on safety improvement rather than punitive enforcement.

Use telematics data for coaching conversations. Review speeding events, harsh braking, and rapid acceleration with drivers. Provide specific feedback and improvement strategies.

Analyze aggregate data to identify systemic issues. Route-specific hazards, scheduling pressures, and training gaps become visible through data analysis.

6. Eliminate Distracted Driving

Distracted driving removes driver attention from the roadway. Mobile phones represent the most common distraction source.

Establish clear policies prohibiting mobile phone use while driving. Define acceptable hands-free communication methods. Communicate expectations during onboarding and ongoing training.

Enforce policies consistently. Use technology to detect phone use violations. Address violations through progressive discipline combined with education.

Address other distraction sources. Eating, adjusting controls, and interacting with passengers divert attention. Train drivers on attention management strategies.

Distraction Prevention Tactics

Encourage drivers to complete administrative tasks while parked. Planning and documentation should occur during rest breaks.

Design dispatch systems that minimize communication needs while driving. Batch route changes and information updates when drivers stop.

Promote situational awareness. Drivers should scan the roadway systematically and maintain appropriate following distances. This creates time to respond to unexpected events.

7. Enforce Speed Management Policies

Speed affects stopping distance and collision severity. Speed management reduces incident frequency and severity.

Set speed policies appropriate to operating conditions. Consider road type, traffic density, and weather conditions. Policies may be more restrictive than posted speed limits.

Use telematics to monitor speed compliance. Identify speeding patterns and address them through coaching. Focus on repeated violations rather than isolated instances.

Explain the physics of speed-related risks. Higher speeds require longer stopping distances. Impact forces increase exponentially with speed.

Speed Management Approaches

Consider vehicle speed limiters for fleet consistency. Electronic speed limiting prevents excessive speeds regardless of driver behavior.

Recognize drivers who maintain appropriate speeds. Positive reinforcement encourages continued safe behavior and influences peer norms.

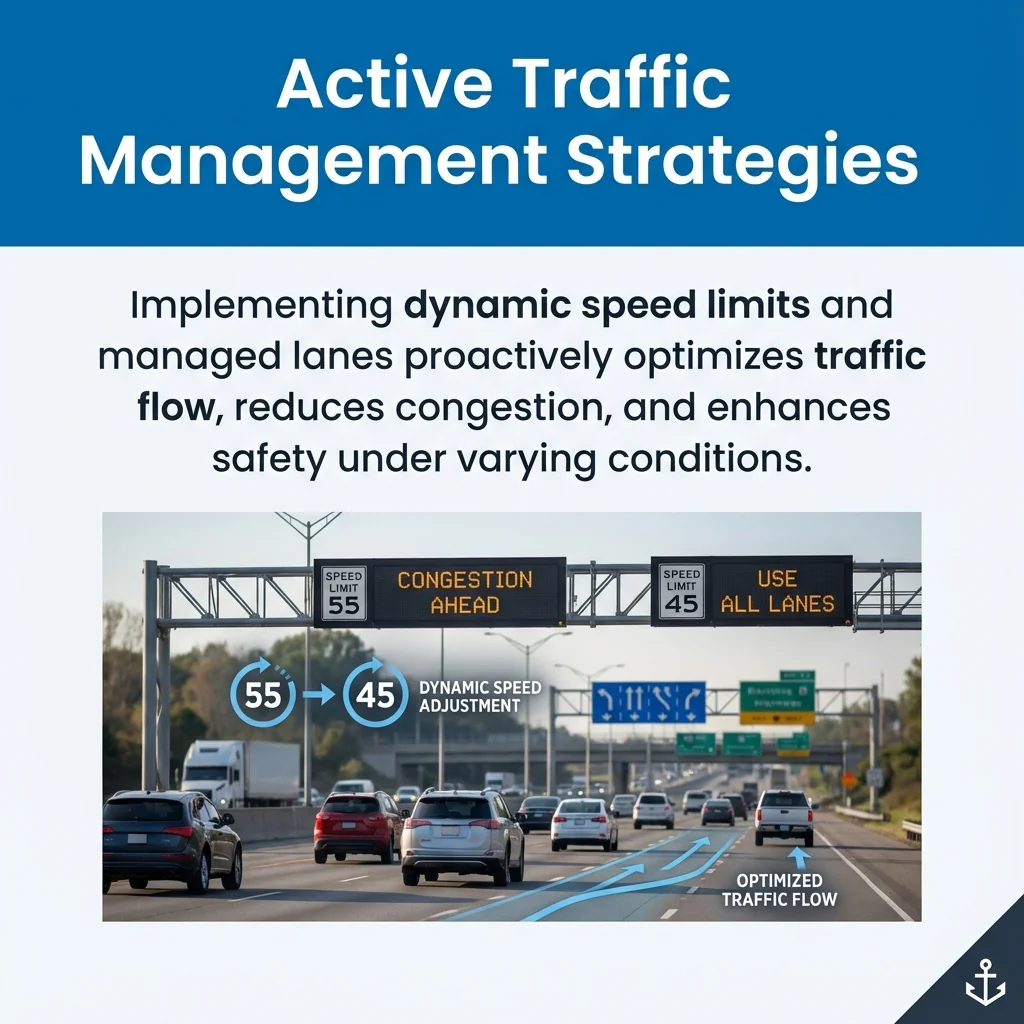

Monitor speed in work zones carefully. Temporary speed reductions protect workers and drivers. The U.S. Federal Highway Administration’s 2024 Urban Congestion Trends report describes Active Traffic Management (ATM) strategies that include dynamic speed management.

8. Conduct Pre-Trip and Post-Trip Inspections

Daily vehicle inspections identify defects before they cause incidents. Structured inspection processes ensure consistency and thoroughness.

Provide drivers with detailed inspection checklists. Cover all safety-critical systems including brakes, tires, lights, and steering components. Require documentation of inspection results.

Train drivers to recognize defects. Explain what constitutes an out-of-service condition. Empower drivers to remove unsafe vehicles from operation.

Post-trip inspections identify issues that developed during operation. This allows repairs before the next dispatch cycle.

Inspection Process Requirements

Allocate adequate time for inspections. Rushed inspections miss critical defects. Include inspection time in route planning and driver schedules.

Create a simple defect reporting system. Drivers should easily communicate issues to maintenance personnel. Track reported defects through resolution.

Review inspection records regularly. Identify patterns that indicate maintenance gaps or driver training needs. Use this data to improve your maintenance program.

9. Establish Safety Planning and Risk Management Protocols

Systematic safety planning identifies hazards and implements controls. The U.S. Public Transportation Agency Safety Plan (PTASP) rules require transit agencies receiving FTA funding to implement Safety Management Systems (SMS).

Conduct regular risk assessments. Identify operational hazards including route-specific risks, cargo handling dangers, and environmental factors. Prioritize risks based on likelihood and severity.

Develop controls for identified risks. Use the hierarchy of controls: elimination, substitution, engineering controls, administrative controls, and personal protective equipment.

Document safety procedures clearly. Make procedures accessible to all affected personnel. Review and update procedures regularly.

Emergency Response Planning

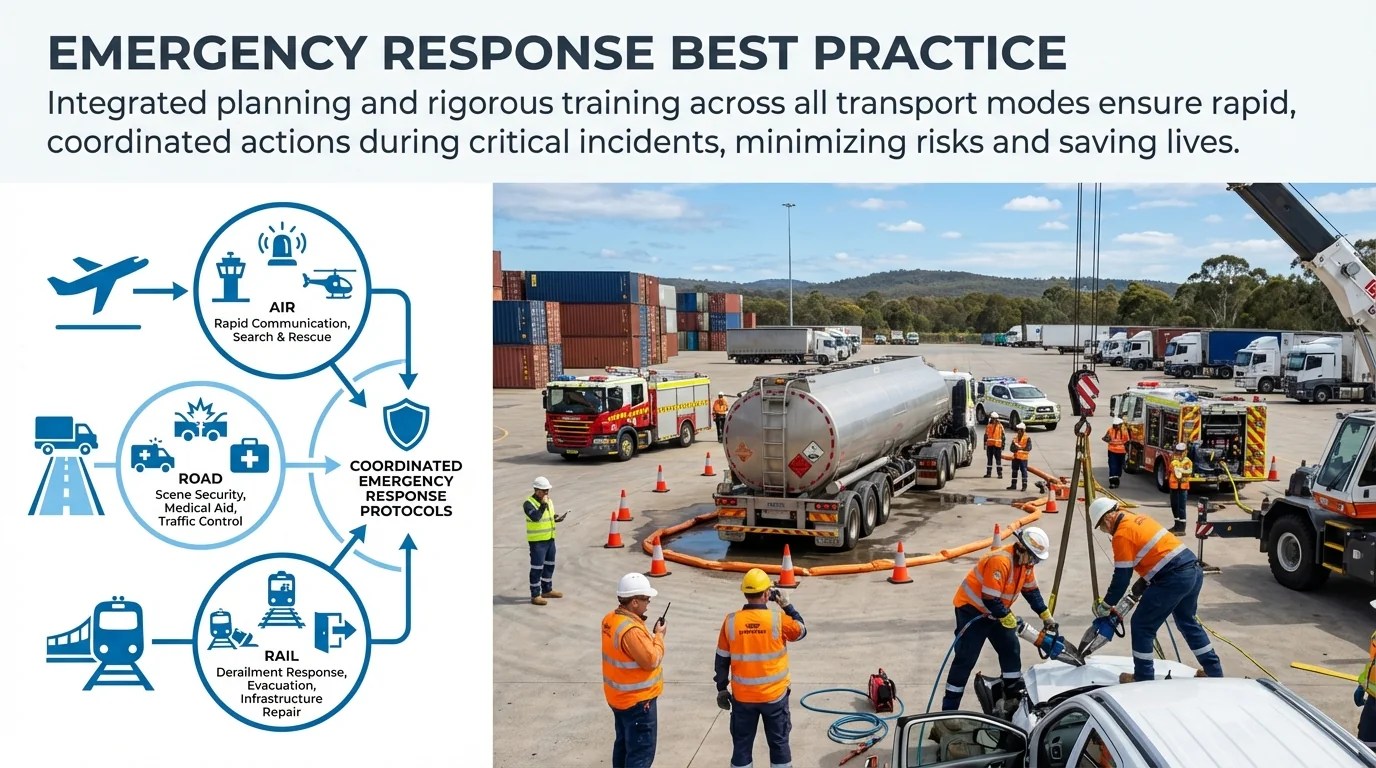

Develop emergency response procedures for likely scenarios. Address vehicle breakdowns, cargo spills, and medical emergencies. The International Air Transport Association (IATA) promotes Emergency Response Planning (ERP) as a safety best practice for airlines, principles applicable across transport modes.

Train drivers on emergency procedures. Conduct drills to verify understanding and identify procedure gaps. Update procedures based on drill results.

Establish communication protocols for emergencies. Ensure drivers can contact dispatch or emergency services quickly. Provide emergency contact information in vehicles.

10. Monitor and Measure Safety Performance

Safety performance measurement drives continuous improvement. Track leading and lagging indicators systematically.

Lagging indicators include incident frequency, severity, and costs. These metrics reveal safety performance but don’t prevent incidents. Track trends over time and compare to industry benchmarks.

Leading indicators predict future performance. Near-miss reports, safety observation participation, and training completion rates indicate safety culture strength.

Review safety metrics regularly with leadership and frontline personnel. Discuss trends, identify improvement opportunities, and assign corrective actions.

Performance Measurement Framework

| Metric Type | Example Indicators | Review Frequency |

|---|---|---|

| Lagging Indicators | Incident rate per million kilometers, severity rate, lost time injuries | Monthly |

| Leading Indicators | Pre-trip inspection completion, near-miss reports submitted, training hours per driver | Weekly |

| Compliance Metrics | Vehicle inspection compliance, driver qualification file completeness, hours-of-service violations | Monthly |

Benchmark performance against industry standards. Identify areas where your organization excels and areas requiring improvement. Use benchmarks to set realistic improvement targets.

Celebrate safety achievements. Recognize milestone periods without incidents. Share success stories across the organization. Positive recognition reinforces desired behaviors.

Implementation Roadmap

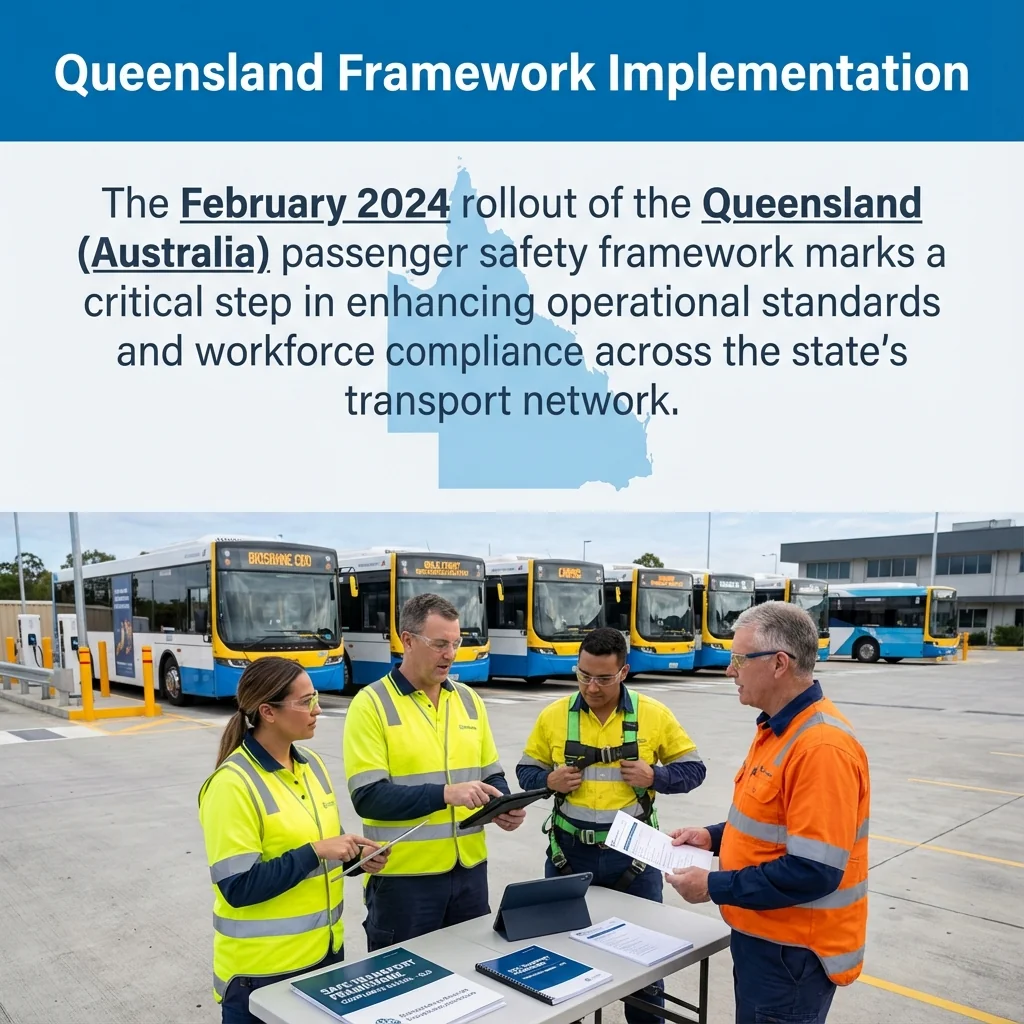

Transport safety management requires sustained effort across multiple domains. In February 2024, Queensland (Australia) implemented a new safety management framework for all road-based public passenger services, demonstrating the ongoing evolution of regulatory frameworks.

Start with leadership commitment and policy development. Establish clear safety expectations and allocate resources appropriately. This foundation supports all subsequent initiatives.

Prioritize high-impact interventions. Address vehicle maintenance systematically before investing in advanced telematics. Build driver capability through training before implementing complex technology solutions.

Measure progress continuously. Track both outcomes and implementation milestones. Adjust strategies based on performance data and emerging risks.

Sustaining Safety Performance

Safety management requires continuous attention. Complacency develops when incidents decline. Maintain focus through regular communication and leadership visibility.

Engage workers in safety improvement. Frontline personnel identify hazards and improvement opportunities. Create mechanisms for worker input and respond to suggestions promptly.

Adapt to changing conditions. New equipment, routes, and regulatory requirements create evolving risks. Review safety programs regularly and update as needed. For more guidance on adapting safety systems, explore implementing a safety management system.

Transport safety management protects your most valuable assets: your people. Systematic approaches to safety culture, vehicle maintenance, driver management, and technology integration reduce incidents and improve operational performance. Start with one tip today. Build momentum through consistent implementation and measurement.

Your transport operation’s safety performance reflects organizational commitment and systematic execution. Review these ten tips against your current practices. Identify gaps and prioritize improvements. Safety excellence emerges from sustained attention to fundamentals combined with willingness to adopt proven practices. For specific insights on enhancing your approach, consider reviewing effective transport safety strategies.

Safety management systems provide structured frameworks for continuous improvement. If you need support developing or auditing your safety program, professional guidance ensures alignment with regulatory requirements and industry best practices. Learn more about common transport safety challenges and how to address them systematically.